- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

800kg

-

Weight (KG):

-

400 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haomai

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800*1200*1500mm

-

Power (kW):

-

26 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Usage:

-

powder or low moisture powder mixing

-

Name:

-

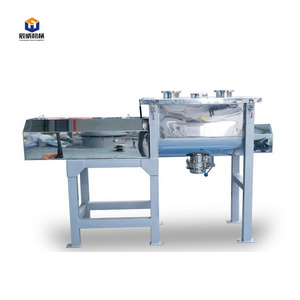

GHJ vertical speed efficiency mixer

-

Stirrer type:

-

Agitator

-

Model:

-

GHL-400

-

Power:

-

21.5kw

-

Weight:

-

250kg

-

Power(W):

-

13.2-48W

-

Product name:

-

Homogenizing Emusifying Machine

Quick Details

-

Barrel Volume (L):

-

850

-

Max. Loading Volume (L):

-

850 L

-

Range of Spindle Speed(r.p.m):

-

4000 - 4500 r.p.m

-

Max. Loading Capacity:

-

800kg

-

Weight (KG):

-

400 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haomai

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800*1200*1500mm

-

Power (kW):

-

26 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Usage:

-

powder or low moisture powder mixing

-

Name:

-

GHJ vertical speed efficiency mixer

-

Stirrer type:

-

Agitator

-

Model:

-

GHL-400

-

Power:

-

21.5kw

-

Weight:

-

250kg

-

Power(W):

-

13.2-48W

-

Product name:

-

Homogenizing Emusifying Machine

Products Description

WORKING PRINCIPLE

The GHJ vertical high-speed mixer is a high-speed and high-efficiency mixer equipment specially developed for the mixing of powder materials. It solves the problem of the process of uniformly mixing various powder raw materials into wet materials in the food, pharmaceutical and other industries for many years. Most of the previous manufacturers used tank mixers, V-type mixers, two-dimensional mixers, three-dimensional mixers and other mixing equipment, but there are common problems such as long mixing time, uneven mixing, small roundness and small pieces. The products have different color, taste and composition, which makes the product quality unstable and the appearance is not beautiful. GHL vertical high-speed mixer is a high-efficiency mixer newly developed by domestic and foreign advanced technology, which solves the problem that powder materials are difficult to mix, and it is difficult to mix with other equipment.

FEATURES

1.Due to centrifugal force, the bottom of the feed slurry leaves along the bottom of the tube wall material up continuously feeding the material from the upper portion of the center to fall down, so that the material circulation spiral. 2.High-speed particle slurry leaves the bulk material leaves the feed slurry delivered completely shattered. 3. Since the two kinds of high-speed rotation of said leaf pulp, so make the material in a relatively short period of time to achieve the purpose of mixing, the mixing speed and the uniformity of the intermediate material are various domestic mixer after mixing can not be achieved without granular , evenness of mixing reaches one hundred percent. 4.Open the discharge valve, the material fast, easy to clean equipment. 5.The aircraft material contact points are made of stainless steel, no material volatilization, deterioration and loss during the mixing process. 6.The machine is suitable for different proportions of dry, wet mixed materials, especially for stirring chicken, powder, granules and other beverages complex mixture of materials.

1.Due to centrifugal force, the bottom of the feed slurry leaves along the bottom of the tube wall material up continuously feeding the material from the upper portion of the center to fall down, so that the material circulation spiral. 2.High-speed particle slurry leaves the bulk material leaves the feed slurry delivered completely shattered. 3. Since the two kinds of high-speed rotation of said leaf pulp, so make the material in a relatively short period of time to achieve the purpose of mixing, the mixing speed and the uniformity of the intermediate material are various domestic mixer after mixing can not be achieved without granular , evenness of mixing reaches one hundred percent. 4.Open the discharge valve, the material fast, easy to clean equipment. 5.The aircraft material contact points are made of stainless steel, no material volatilization, deterioration and loss during the mixing process. 6.The machine is suitable for different proportions of dry, wet mixed materials, especially for stirring chicken, powder, granules and other beverages complex mixture of materials.

Specification

|

Model

|

Volume

|

Kg/Batch

|

Installed power

|

Dimension(mm)

|

|

GHJ-350

|

350

|

150

|

13.2

|

1500*1000*1400

|

|

GHJ-400

|

500

|

300

|

21.5

|

1600*1100*1400

|

|

GHJ-850

|

850

|

400

|

26

|

1800*1200*1500

|

Applied material

It is widely used in rubber, dyeing and other industries. Such as plastic modified coloring, resin, color masterbatch and calcium carbonate additives, polytetrafluoroethylene (Teflon) filled masterbatch. The main structure consists of mixing chamber, stirring paddle, deflector, unloading device, driving device and control system.

Detailed Images

Packing & Delivery

Hot Searches