- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110-380V, accroding to your standard

-

Power:

-

Can be customized

-

Dimension(L*W*H):

-

68*95*74cm, can be customized

-

Weight (KG):

-

500

-

Product Name:

-

aluminum tank machine chrome tank rotary tank for electroplating

-

Coatings:

-

Galvanizing, Copper plating, Nickel plating, Gold plating

-

Available for:

-

Metal Surface Plating

-

Heating model:

-

Electric Heating

-

Operation:

-

Semi-auto

-

Application:

-

Surface Treatment

-

OEM Service:

-

Accept

-

Size:

-

Customer's Reuqest

-

Advantage:

-

High Strength

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

electroplating

-

Brand Name:

-

Guangcai

-

Voltage:

-

110-380V, accroding to your standard

-

Power:

-

Can be customized

-

Dimension(L*W*H):

-

68*95*74cm, can be customized

-

Weight (KG):

-

500

-

Product Name:

-

aluminum tank machine chrome tank rotary tank for electroplating

-

Coatings:

-

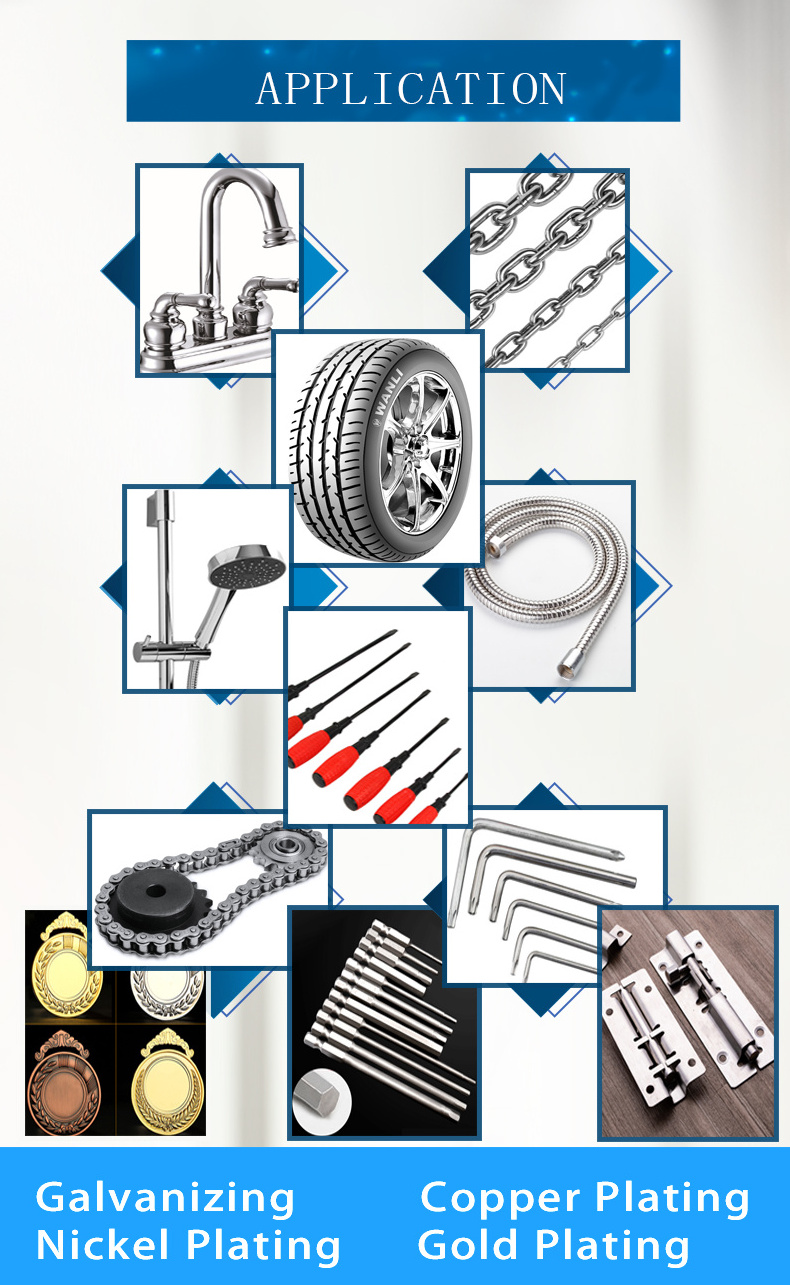

Galvanizing, Copper plating, Nickel plating, Gold plating

-

Available for:

-

Metal Surface Plating

-

Heating model:

-

Electric Heating

-

Operation:

-

Semi-auto

-

Application:

-

Surface Treatment

-

OEM Service:

-

Accept

-

Size:

-

Customer's Reuqest

-

Advantage:

-

High Strength

-

After Warranty Service:

-

Video technical support

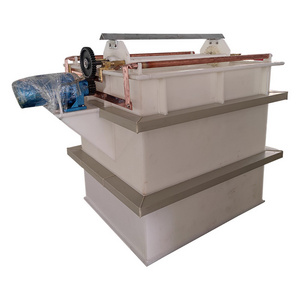

Aluminum tank machine chrome tank rotary tank for electroplating

| Product Name | Anodizing rotary tank for electroplating machine chrome plating tank |

| Usage | Metal Surface Plating |

| Material | PP plate, Motor, and so on |

| Heating source | Electricity |

| Performance | High efficiency (> 90%) |

| Feature | Power Saving (over 30%) |

| Application | Galvanizing, Copper plating, Nickel plating, Gold plating |

| Size | Can be customized |

| Volume | According to your application performance |

| Warranty time | 1 year |

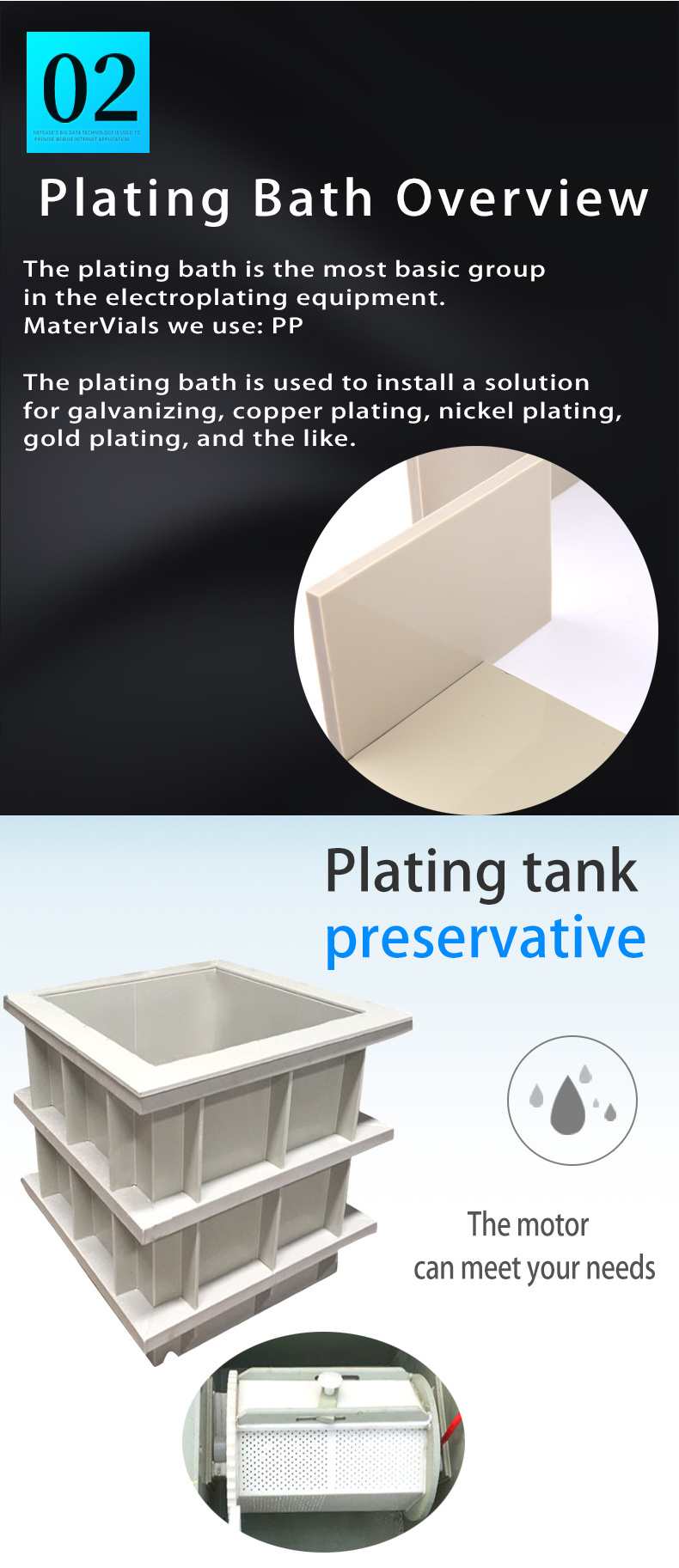

The plating tank is used to install a solution for galvanizing, copper plating, nickel plating, gold plating, and the like. The cathode moving plating tank is composed of a steel tank lined with a soft polyvinyl chloride plastic tank, a conductive device, a steam heating tube and a cathode moving device. The tank body can also be made of steel-framed with rigid polyvinyl chloride plastic. The choice of tank structure depends on the nature of the plating tank and the temperature. It consists of a motor, a reducer, an eccentric disk, a connecting rod and a pole supporting roller.

Plating tank size setting

When determining the size of the plating tank , the following three basic conditions must be met:

1 ) to meet the plating requirements of the machined parts, such as the ability to completely immerse the parts to be electroplated to the entire surface;

2 ) Prevent the electrolyte from overheating;

3 ) It can maintain a certain stability of the electrolyte component content in the plating production cycle.

Of course, we must also consider the overall coordination of the production line, to meet the requirements of the rationality of the layout of the plating shop.

Linyi Guangcai Metal Surface Technology Co., Ltd. was established in 1999, specializing in the research and development and manufacture of electroplating equipment. Our products include fully automatic, semi-automatic, manual plating equipment and other metal surface treatment equipment and auxiliary equipment, and we have professional electroplating technicians to ensure that all products meet international quality standards. Because we can meet the different needs of our customers, our company is highly valued by different markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We value the quality of our products, pay more attention to our brands and services, and look forward to being your next business partner. Let us make the world a better place!