- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3442mm*3000mm*16800mm

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

No overseas service provided

-

Usage:

-

Oil Well

-

Certification:

-

API

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HH

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3442mm*3000mm*16800mm

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

No overseas service provided

-

Usage:

-

Oil Well

-

Certification:

-

API

Products Description

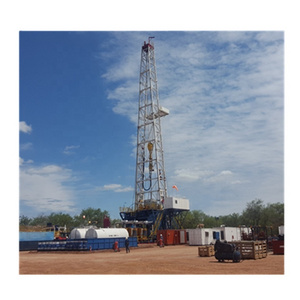

Product information of ZJ50/3150DZ DC frilling Rig

Features

1. The drawworks is one-piece single shaft structure, compact, light-weighted, higher transmission efficiency, less maintenance and hook hoisting speed is 0~1.3m/s stepless speed regulation.

2. Drawworks main brake is hydraulic disc brake. Assistant brake is dynamic brake. Brake unit automatically detects electric voltage on DC side and when the reading exceeds preset value, extra dynamics is consumed on brake resistance and tripping in speed (incl. suspension) is controlled to your will.

3. Drawworks is equipped with motor auto-bit-feeding device which adopts vector control technique enabled with speed sensor and realizes constant WOB auto-bit-feeding and zero speed suspension function. WOB is smooth and even and bit-feeding is sensitive and accurate and mechanical penetration is increased. As emergency response to main system failure, maximum drill string weight can be hoisted.

4. Traveling block position automatic control system prevents “collide up and impact down” accidents. Position control is achieved by real time detection of traveling block position and PLC calculation and analysis. When traveling block reaches alarming position, “soft-stop” control procedure of “alarming-slowdown-stop” is trigger automatically. Accurate real time position indication of traveling block makes driller’s operation easy.

5. Field-bus control system forms a communication network founded on PROFIBUS-DP. The network enables data exchange and control of driller control cabin, auto-bit-feeding system, unitized instrumentation, traveling block position control system and VF speed regulation cabinet. Machine-human interface (touch screen) is used for displays of working state and parameters and realization of control function.

6. Intelligent driller control cabin is fully-equipped with real time display of operating parameter, electrical system monitoring and display and failure display and alarm. Driller is changing from skillful worker to knowledge technician. Driller’s duty focus on acquisition of data and optimize drilling parameter in response to well condition and engineering instruction to realize safe, efficient and cost-effective drilling operation.

7. The rig satisfies HSE regulations.

8. The rig performance and technical parameters comply with SY/T5609—1999 standard. Main parts conform to API spec and marked with API monogram.

Features

1. The drawworks is one-piece single shaft structure, compact, light-weighted, higher transmission efficiency, less maintenance and hook hoisting speed is 0~1.3m/s stepless speed regulation.

2. Drawworks main brake is hydraulic disc brake. Assistant brake is dynamic brake. Brake unit automatically detects electric voltage on DC side and when the reading exceeds preset value, extra dynamics is consumed on brake resistance and tripping in speed (incl. suspension) is controlled to your will.

3. Drawworks is equipped with motor auto-bit-feeding device which adopts vector control technique enabled with speed sensor and realizes constant WOB auto-bit-feeding and zero speed suspension function. WOB is smooth and even and bit-feeding is sensitive and accurate and mechanical penetration is increased. As emergency response to main system failure, maximum drill string weight can be hoisted.

4. Traveling block position automatic control system prevents “collide up and impact down” accidents. Position control is achieved by real time detection of traveling block position and PLC calculation and analysis. When traveling block reaches alarming position, “soft-stop” control procedure of “alarming-slowdown-stop” is trigger automatically. Accurate real time position indication of traveling block makes driller’s operation easy.

5. Field-bus control system forms a communication network founded on PROFIBUS-DP. The network enables data exchange and control of driller control cabin, auto-bit-feeding system, unitized instrumentation, traveling block position control system and VF speed regulation cabinet. Machine-human interface (touch screen) is used for displays of working state and parameters and realization of control function.

6. Intelligent driller control cabin is fully-equipped with real time display of operating parameter, electrical system monitoring and display and failure display and alarm. Driller is changing from skillful worker to knowledge technician. Driller’s duty focus on acquisition of data and optimize drilling parameter in response to well condition and engineering instruction to realize safe, efficient and cost-effective drilling operation.

7. The rig satisfies HSE regulations.

8. The rig performance and technical parameters comply with SY/T5609—1999 standard. Main parts conform to API spec and marked with API monogram.

|

Rig model

|

ZJ50/3150DB

|

|

||

|

Nominal drilling depth (114mm drill pipe) m

|

3500-5000

|

|

||

|

Max. hook load kN

|

3150

|

|

||

|

Max. drill line no.

|

12

|

|

||

|

Wireline diameter mm(in)

|

35 (13/8)

|

|

||

|

Sheave OD mm(in)

|

1270 (50)

|

|

||

|

Swivel center pipe bore diameter mm(in)

|

75 (3)

|

|

||

|

Drawworks rated power kW(hp)

|

1100 (1500)

|

|

||

|

Drawworks gear

|

1 stepless change

|

|

||

|

Rotary table opening diameter mm(in)

|

698.5 (271/2)

|

952.5 (371/2)

|

||

|

Rotary table gear

|

1 stepless change

|

|

||

|

Power/mud pump set kW(hp)

|

960 (1300)

|

1180 (1600)

|

||

|

Mast effective height m(ft)

|

45 (147)

|

|

||

|

Drill floor height m(ft)

|

7.5 (25)

|

9 (30)

|

||

|

Drill floor clearance m(ft)

|

7.62 (25)

|

8.92 (29.3)

|

||

|

Note: DB – AC VF drive rig

|

|

|

||

Marketing Campaign

Details Images

Product packaging

According to the volume and weight of the product and export requirements, provide multi-layer boxes and iron box packaging.

Transportation is based on customers in different regions using steam, rail, road and air transportation.

Transportation is based on customers in different regions using steam, rail, road and air transportation.

Hot Searches