- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Haixu Abrasives

-

Model Number:

-

AFS40-AFS50 Ceramic foundry sand

-

Use:

-

foundry

-

Certification:

-

ISO9001

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

AFS15-AFS210 Ceramic foundry sand

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Haixu Abrasives

-

Model Number:

-

AFS40-AFS50 Ceramic foundry sand

-

Use:

-

foundry

-

Certification:

-

ISO9001

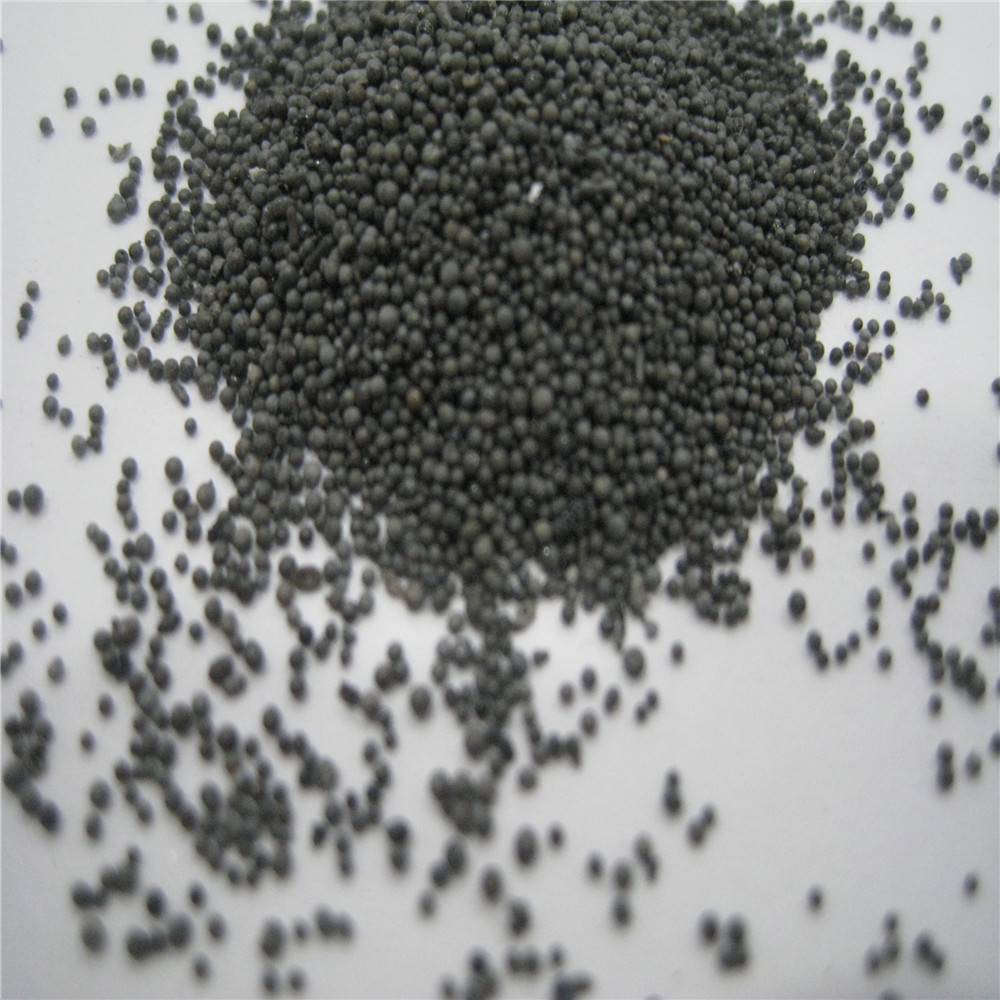

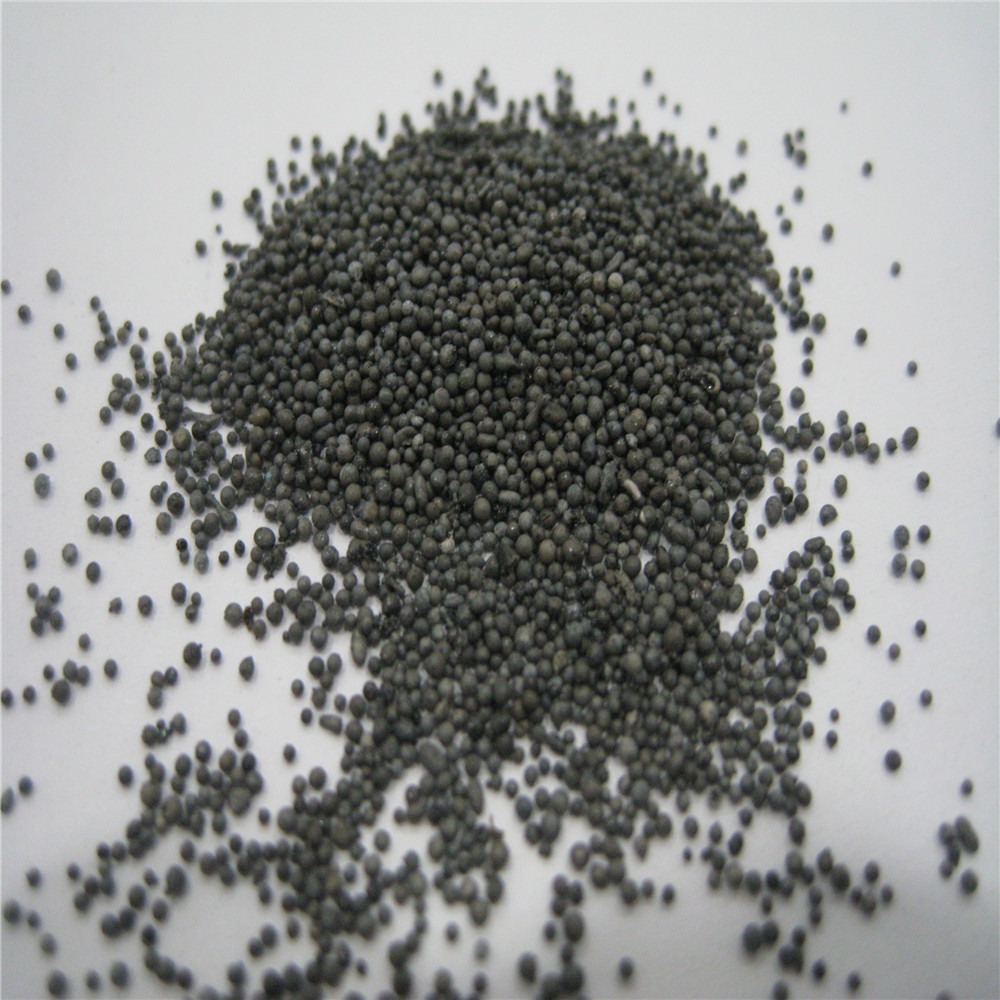

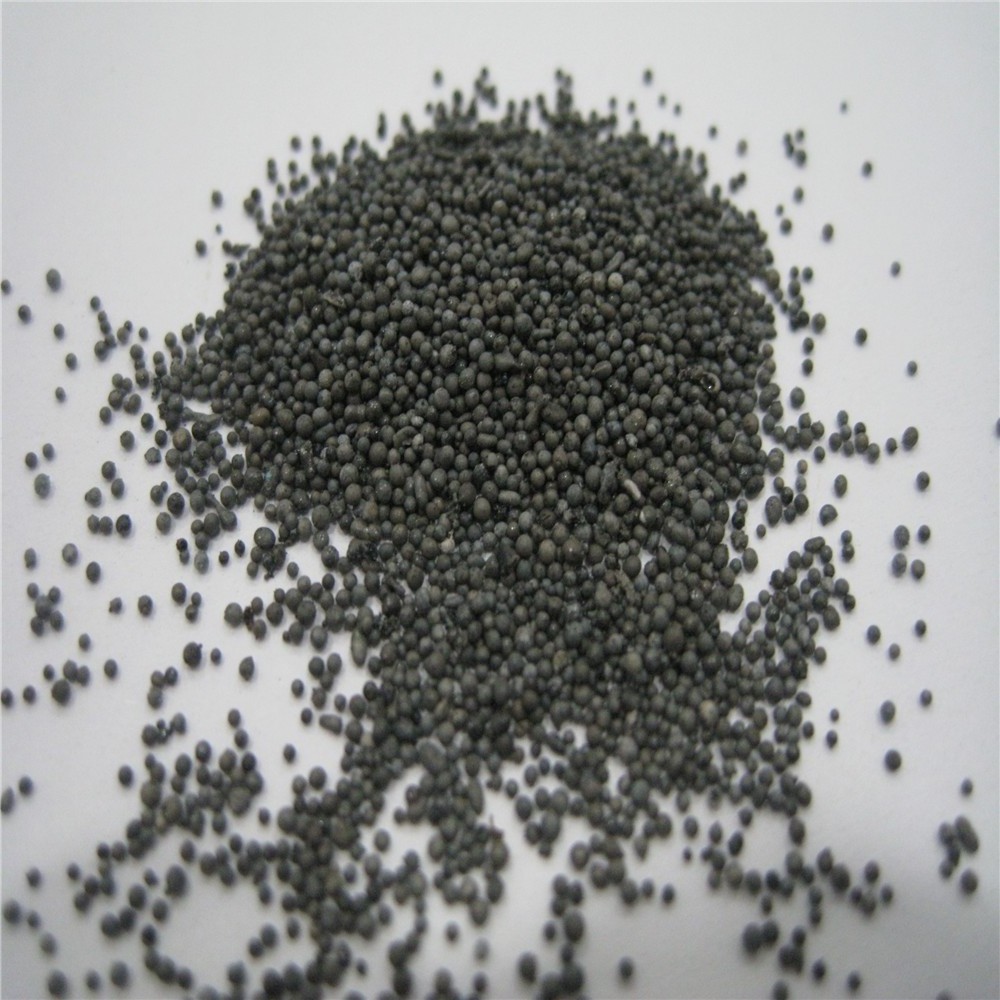

Ceramic foundry sand for Resin Coated Sand Casting

Ceramic foundry sand is made of high quality bauxite, through the process of electrofusion, granulation, screening and so on, which is made of very ball-like refractory particles.

Product features:

1. The granule is spherical, with good fluidity and easy filling;Smooth surface, compact structure, small surface area, less consumption of binding dose and curing agent, at the same time with a high degree of compactness, metal liquid is not suitable for infiltration, can prevent mechanical penetration of sticky sand.

2, high refractory, high temperature chemical stability, belongs to the neutral material, is not easy to be metal compound erosion, can prevent chemical sand.

3. Small thermal expansion rate can effectively prevent gradual expansion defects.

4, good crushing resistance, not easy to produce dust, conducive to environmental protection, and good recycling performance, can reduce costs, save resources.