- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

12KW

-

Dimension(L*W*H):

-

2600*1600*1850mm

-

Weight:

-

3200 kgs

-

Warranty:

-

1 year

-

Production:

-

90-110PCS/MIN

-

Type:

-

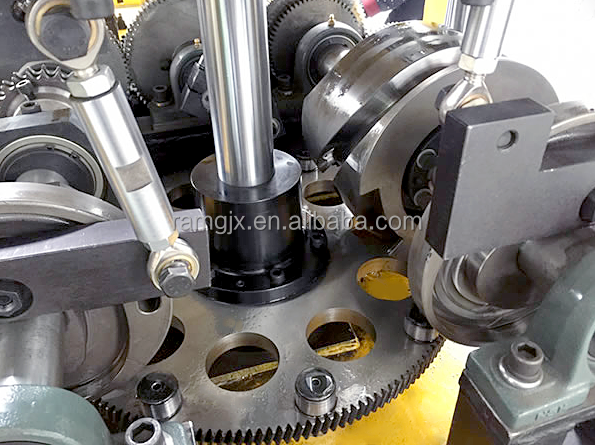

OPEN CAM WITH THE GEAR IN AUTOMATIC LUBRICATION SYSTEM

-

SIZE:

-

4-16OZ

-

Raw material:

-

PE Coated Paper

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MINGGUO

-

Model Number:

-

MG-C800

-

Voltage:

-

220V/380V

-

Power:

-

12KW

-

Dimension(L*W*H):

-

2600*1600*1850mm

-

Weight:

-

3200 kgs

-

Warranty:

-

1 year

-

Production:

-

90-110PCS/MIN

-

Type:

-

OPEN CAM WITH THE GEAR IN AUTOMATIC LUBRICATION SYSTEM

-

SIZE:

-

4-16OZ

-

Raw material:

-

PE Coated Paper

Description

MG-C800 HIGH SPEED PAPER CUP MACHINE use the three turnplates. The machine adopts desktop layout, insulate the transmission part and mold. The transmission part is arranged in the frame box under the machine table, lubrication spray automatically. The machine adopts open cam design, interrupted division design, gear drive, longitudinal axis design. So they can reasonably distribute each part function. On table setting each mold which makes easy clean and maintain. MG-C800 in total two course for top curling forming , first course rotate top curling ,and second that heating and forming , thus the cup forming will be more perfectly. MG-C800 electric parts adopt PLC control, photoelectric tracking and monitoring the whole process, also the servo control feeding. Suitable for 4 to 16oz hot & cold paper cups .

MG-C800 Using CCD image detection system (optionally), it will detected the broken, tainted, and molding defects cups. without manual selection,it can reduce secondary pollution.

MG-C800 high speed paper cup machine simplifies paper cup forming process. This machine can finish paper feeding, gluing, cup-bottom feeding heating, knurling, cup-mouth curling, cup-collecting, etc .It is especially suitable for making paper cups with height of 50-135mm.

Technical specification:

|

Model |

MG-C800 |

|

Weight |

3200 KG |

|

Dimension |

2600x1600x1850 MM |

|

Total power |

12KW 380V50Hz |

|

Air supply requirement |

0.5-0.8MPa , 0.4cube/min |

|

Capacity |

90-110 PCS/MIN |

|

Paperspecification |

SINGLE /DOUBLE PE COATED PAPER |

|

Paper grams |

190-350g/mm |

|

Cup size |

4-16OZ |

Features

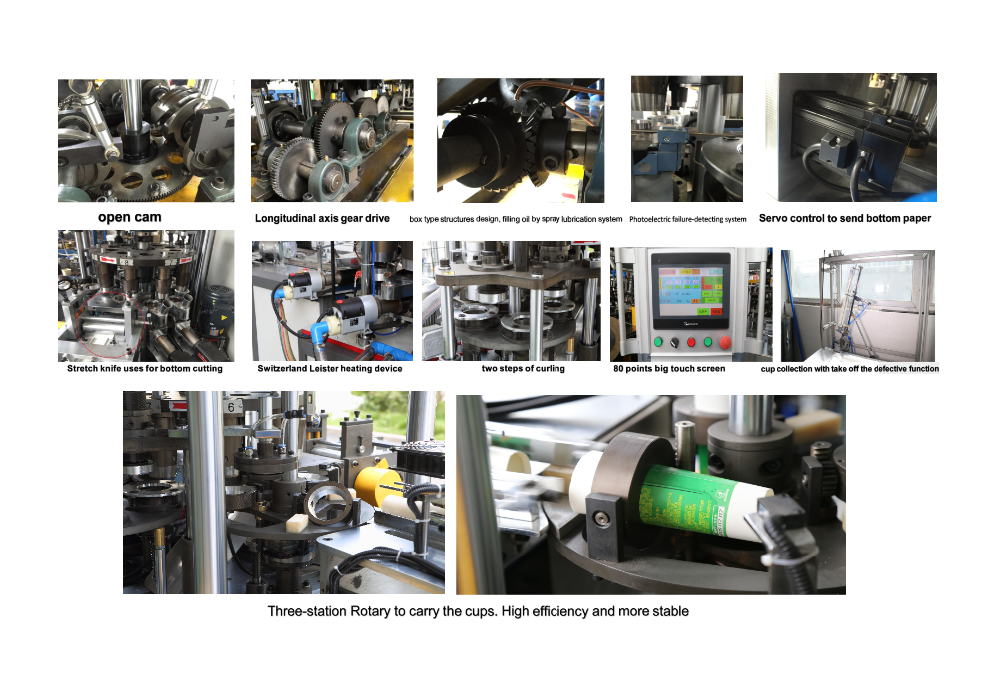

A. The machine adopts open cam type structure, high precision, large out-put and long life.

B. Longitudinal axis gear drive. This make up the chain drive jitter and instability's weakness.

C. Whole machine is box type structures design, filling oil by spray lubrication system So that it can run fast and stably.

D. Photoelectric failure-detecting system is available. PLC control system for the whole cup forming process.

E. Servo control to send bottom paper of cup, deliver bottom when cup tube come, otherwise no bottom delivery.

F. Stretch knife uses for bottom cutting. Easy changed and more stable.

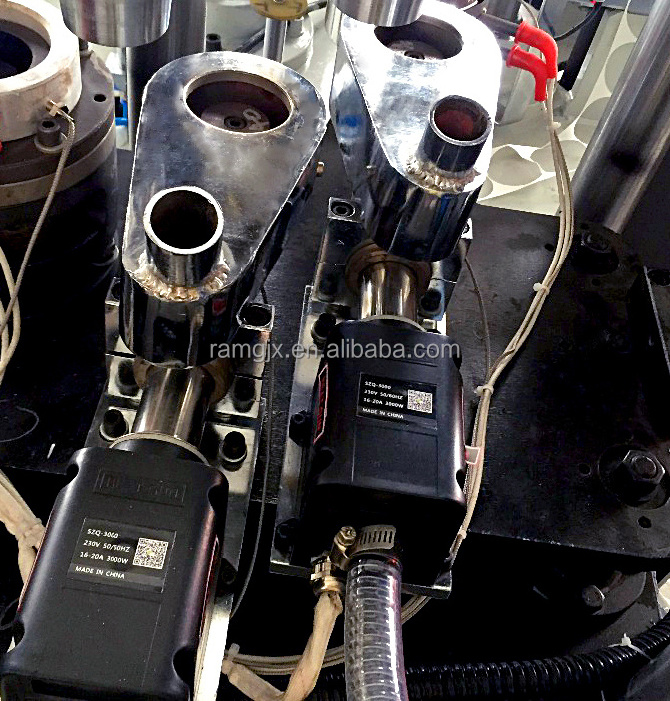

G. Switzerland Leister heating device is equipped for cup body and bottom sealing, bottom are heated at first before they are feeding, thus improving heating effect and helping guarantee knurling.

H. Curling. There are two steps of curling. The first one is curl the cup top and the second consolidate the cup curling.

I. It adopts the t hree-station Rotary to carry the cups. High efficiency and more stable.

J. The cup collection with take off the d efective function .

Sample

Certificate

Packing & Shipping