- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fect

-

Voltage:

-

380V 3P

-

Power:

-

3kw paper lunch box making machine

-

Dimension(L*W*H):

-

3450mm*1250mm*1480mm

-

Weight:

-

1500 kg

-

Marketing Type:

-

paper lunch box making machine

-

Name:

-

paper lunch box making machine

-

Box Length:

-

L100-450mm

-

Edge banding height:

-

H 15-200mm

-

Box Width:

-

B100-580/385mm

-

Max. Paper thickness:

-

1.5mm

-

fast food box machine Speed:

-

180pcs/min

-

lunch box making machine:

-

Paper Boat Tray Machine

-

burger box:

-

cake box making machine

-

take away food box:

-

corrugated box making machine

-

Keyword:

-

paper lunch box making machine

Quick Details

-

Production Capacity:

-

180pcs/min

-

Product Type:

-

paper lunch box making machine

-

Processing Type:

-

paper lunch box making machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fect

-

Voltage:

-

380V 3P

-

Power:

-

3kw paper lunch box making machine

-

Dimension(L*W*H):

-

3450mm*1250mm*1480mm

-

Weight:

-

1500 kg

-

Marketing Type:

-

paper lunch box making machine

-

Name:

-

paper lunch box making machine

-

Box Length:

-

L100-450mm

-

Edge banding height:

-

H 15-200mm

-

Box Width:

-

B100-580/385mm

-

Max. Paper thickness:

-

1.5mm

-

fast food box machine Speed:

-

180pcs/min

-

lunch box making machine:

-

Paper Boat Tray Machine

-

burger box:

-

cake box making machine

-

take away food box:

-

corrugated box making machine

-

Keyword:

-

paper lunch box making machine

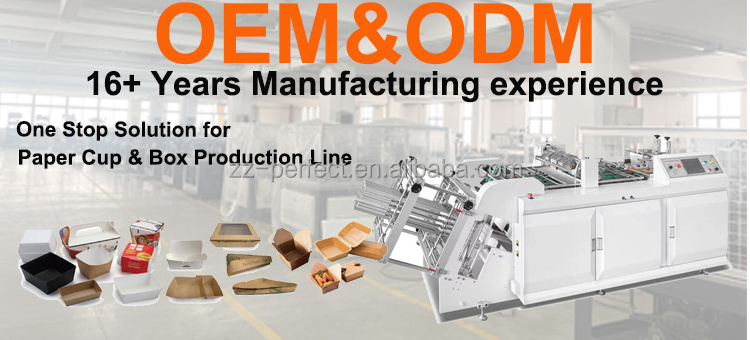

♦ Application♦

automatic small corrugated cake box making machine to make cardboard boxes is a special forming machine that produces various fast food box container, such as , burger box, one block box, food pail box( take away box), hamburger box, French Fries box take out container and other related containers made by aluminum foil paper and double PE coated paper.

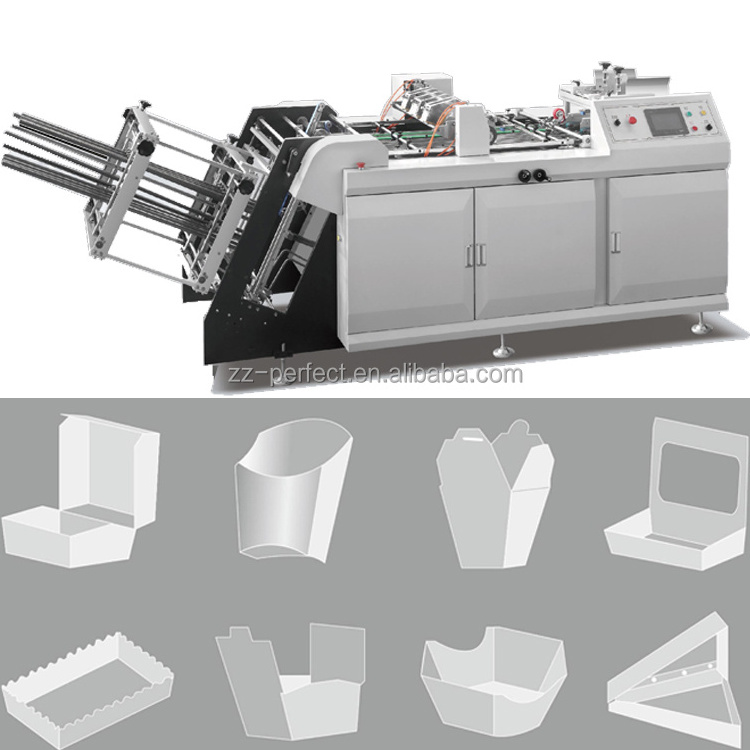

♦Techincal parameter♦

|

Box Length |

L100-450mm |

|

Box Angles |

5°- 40° |

|

Box Width |

B100-580/385mm |

|

Edge banding height |

H 15-200mm |

|

Occupancy of machine |

1.2m*4m |

|

Product speed |

Max 180pcs/min |

|

Bonding/Gluing device |

Water-based adhesive |

|

Paper thickness |

Max 1.5mm |

|

Electrical requirement |

4.5kw/h |

|

Air requirement |

6kg/cm²*200L/min |

|

Equipment size |

2.95*1.3*1.3m |

|

G.W. |

2000KG |

|

Package measurements |

3.55m*1.35m*1.7m (L*W*H) |

1) Short time required to change the mould to make various shape paper box

2) Water-based adhesive is belongs to food-grade. It is safe for human body.

3) All of the molds are made of Pine materials, which is more durable.

4) Automatically collecting. According to clients’ request, we can add calculator for counting the amount of boxes and set a mark per 100/200 boxes in order to counting easily.

5) PLC control system, during running period, the machine will stop automatically when short of paper, ensure safety for operator.

♦ Features♦

- It adopts micro-computer, PLC

- alternating current frequency converter

- the vacuum-sucking paper feeding

- auto gluing

- automatic paper tape counting

- chain drive

|

1. Paper feeding The feeding part adopts mechanical rubber-wheel paper feeding structure, which can feeding paper in any size and specification without adjust in addition. The machine adopts chain drive to guarantee smooth running,hard-wearing.the chain drive of every unit are separated to reduce noise and workload, increase the stability ,The transmission width can be adjusted by the screw rod easily and conveniently. |

|

|

2. Gluing Use water-based adhesive coat the roller by foam, and apply on the paper glue position. |

|

|

3. Forming device and box collector The mold height is adjustable and can be made into various specifications and shapes, such as the taper box and flapped hamburger box etc.Automatic counter can be set mark 100/200pcs one time for paper box subgroup packing.

|

|

| Optional Hot-melt adhesive system | |

| Electric equipment | |

.

Paper box erecting machine Customer cases