- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Electronic Potting And Assembly UV Cure Adhesives

-

Material:

-

One-component potting materials

-

Storage temperature:

-

-20-8℃

-

Curing method:

-

Heat curing

-

Color:

-

Black

-

Use:

-

Low temperature fast curing

-

Product Description:

-

Suitable for low-temperature curing of heat-sensitive components

-

Curing system:

-

Heat cured or UV cured

-

Feature:

-

High temperature stability and heat shock resistance

-

Glue type:

-

Epoxy resin-based

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DeepMaterial

-

Model Number:

-

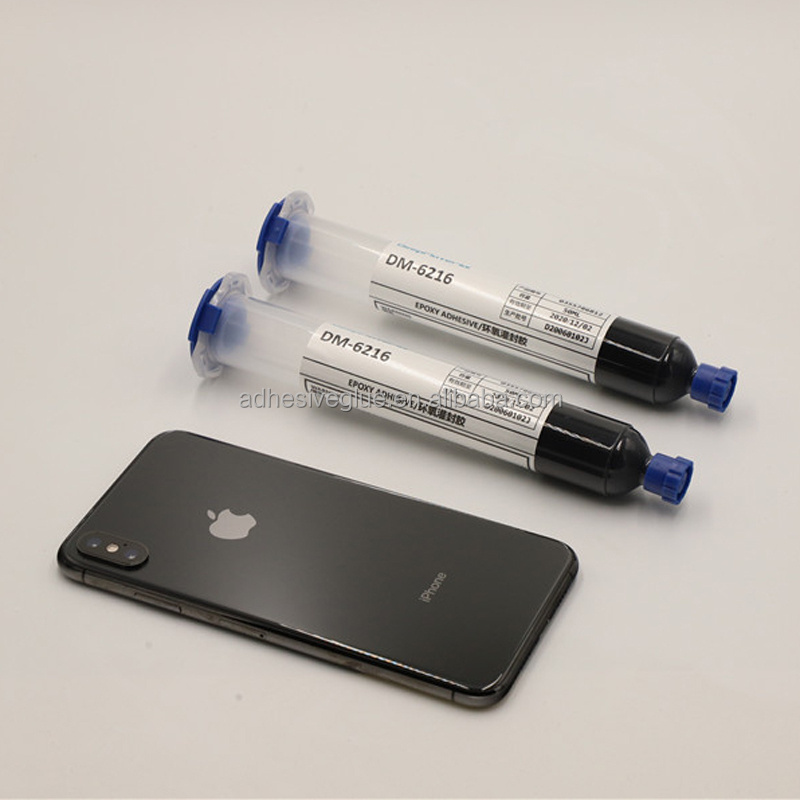

DM-6216

-

Product name:

-

Electronic Potting And Assembly UV Cure Adhesives

-

Material:

-

One-component potting materials

-

Storage temperature:

-

-20-8℃

-

Curing method:

-

Heat curing

-

Color:

-

Black

-

Use:

-

Low temperature fast curing

-

Product Description:

-

Suitable for low-temperature curing of heat-sensitive components

-

Curing system:

-

Heat cured or UV cured

-

Feature:

-

High temperature stability and heat shock resistance

-

Glue type:

-

Epoxy resin-based

DeepMaterial High Viscosity Good Flexibility Electronic Potting And Assembly UV Cure Adhesives For Camera Module Cable Fixed

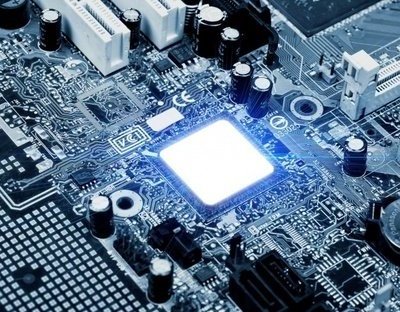

DeepMaterial's smart card chip encapsulant prevents damage to sensitive contacts and protects the chip itself from scratches, dust and moisture. DeepMaterial 's chip encapsulant is solvent-free and has high ionic purity, which also protects the chip card from internal corrosion and reduces local galvanic coupling. By reducing material stress, glue can greatly improve the reliability and durability of chips.

DeepMaterial chip encapsulant is based on UV-curable epoxy resin, which can be cured in seconds under UV light. This makes it suitable for fully automated mass production.

Heat-cured sealants, on the other hand, have the advantage of curing in dark areas where UV light cannot reach. Overcoats or coatings with dark shades are usually heat cured only.

The chip underfill developed by DeepMaterial can be used for smart card production and chip packaging glue. Chip encapsulant with different curing time and viscosity can be customized according to customer requirements.

DeepMaterial DM-6216 high temperature resistant epoxy resin adhesive is a black epoxy resin potting adhesive with fast curing speed, high bonding strength, good hardness and good toughness after curing. It is widely used in electrical and electronic, craft gifts, petrochemical industry, etc. Encapsulation bonding between metals, ceramics, wood, glass and rigid plastics in the industry.

Encapsulation E poxy Adhesives S election

|

Product Series |

Product N ame |

Product T ypical A pplication |

|

Encapsulation Adhesive |

DM-6216 |

It is an epoxy resin encapsulant, suitable for applications requiring excellent handling properties. The cured material has severe thermal shock and provides continuous heat resistance to 177°C. It is especially suitable for the packaging of transistors and similar semiconductors. It can be used for the packaging of watch integrated circuits and components, and for the packaging of sensitive plug-ins on PCB boards, transistors, smart cards and IC cards. |

|

DM-6261 |

Component encapsulation adhesive, used for PCB board sensitive plug-in packaging, excellent viscosity stability, easy to control the size of the adhesive. After passing 1000H temperature/humidity/deviation test and thermal cycle to 125℃. The special viscosity stabilized at 25°C provides a more easily controlled size using conventional time/pressure dispensing equipment. |

|

|

DM-6258 |

This product provides excellent environmental and thermal protection for packaged components. This product is especially suitable for the protection of sensors and precision components used in harsh environments such as automobiles. |

|

|

DM-6286 |

Epoxy resin encapsulants are designed for applications that require excellent handling properties. Used for IC and semiconductor packaging, with good heat cycle ability, the material can withstand thermal shock continuously to 177°C |

Encapsulated Epoxy Adhesive Product Data Sheet

|

Product line |

Product Series |

Product name |

Colour |

Typical viscosity (cps) |

Initial fixation time / full fixation |

Curing method |

TG/℃ |

Hardness/D |

Store/℃ /M |

|

Epoxy based |

Encapsulation Adhesive |

DM-6216 |

Black |

58000-62000 |

150℃ 20min |

Heat curing |

126 |

86 |

2-8/6 M |

|

DM-6261 |

Black |

32500-50000 |

140℃ 3H |

Heat curing |

125 |

* |

2-8/6 M |

||

|

DM-6258 |

Black |

50000 |

120℃ 12min |

Heat curing |

140 |

90 |

*-40/6 M |

||

|

DM-6286 |

Black |

62500 |

120℃ 30min1 150℃ 15min |

Heat curing |

137 |

90 |

2-8/6 M |

1. What’s the minimum order quantity(MOQ)?

- Minimum 1 unit, small batch and large volumes are acceptable.

2. When can I get the quotation?

- We usually respond within 24 hours on working days receiving your messages.

After we receive the TDS report or sample, we will forward to you with quotation within one week.

3. Which is the safe payment method to trade?

- We accept T/T, LC, Paypal, Trade Assurance and Secure payment on Alibaba platform.

4. How long does it take to deliver?

- For standard adhesive, it will be 7 days for manufacturing.

- For non-standard adhesive, it will be negotiated customized according to your requirements.

5. What’s the shipping method?

- We are able to ship worldwide where Ocean shipping or Air shipping can reach.

- We have a professional packaging team. Products will be packed safely and protectively.

Our Factory specializing in adhesives for semiconductor and electronic applications and surface protection materials for chip packaging and testing. Based on the core technology of adhesives, DeepMaterial has developed adhesives for chip packaging and testing, circuit board-level adhesives, and adhesives for electronic products. Based on adhesives, it has developed protective films, semiconductor fillers, and packaging materials for semiconductor wafer processing and chip packaging and testing. To provide electronic adhesives and thin-film electronic application materials products and solutions for communication terminal companies, consumer electronics companies, semiconductor packaging and testing companies, and communication equipment manufacturers,to solve the above-mentioned customers in process protection, product high-precision bonding, and electrical performance. Domestic substitution demand for protection, optical protection, etc.

The Factory continues to modify the application of adhesives and resin materials, and the company's strategic plan will focus on the development of EB curing adhesives and new semiconductor materials. EB curing adhesives and resins will break through the technical bottlenecks such as curing time, open operation time and bonding strength of any structural adhesive in the world, thereby forming no open time, no curing time (super fast nanosecond curing), high viscosity new adhesives with high bonding strength will break the current use of electronic products and component assembly, precision sensors, PCB circuit board substrate processing, PCB circuit board etching processing (etching process above 195nm), new energy (battery and wind power potting, bonding). The market adhesive application rules for the building materials industry (composite panels); the application of EB curing and irradiation technology in the direction of semiconductor materials will break through the current technological monopoly of semiconductor protective materials by Japanese companies and achieve technical overtaking on a curve.