- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1000 kg

-

Product name:

-

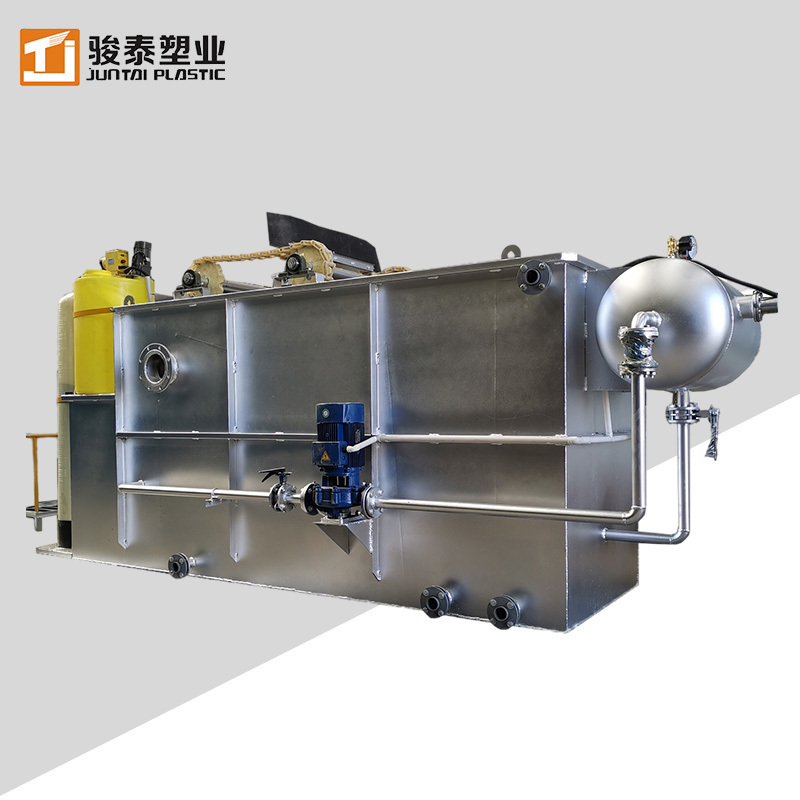

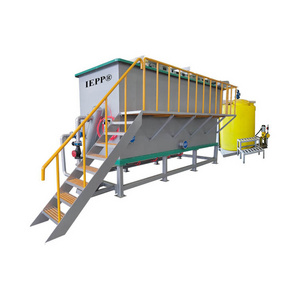

Dissolved Air Flotation

-

Color:

-

Grey

-

Net water:

-

2(m3/h)

-

Processing custom:

-

Support

-

Turbidity of inlet water:

-

500(mg/l)

-

Turbidity of effluent:

-

3(mg/l)

-

Material:

-

Carbon Steel / Stainless Steel

-

Application:

-

Solid-liquid Separation

-

Delievery time:

-

After get the deposit within 15 days

-

Usage:

-

wastewater pre-treatment

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JUNTAI

-

Weight:

-

1000kg

-

Weight (KG):

-

1000 kg

-

Product name:

-

Dissolved Air Flotation

-

Color:

-

Grey

-

Net water:

-

2(m3/h)

-

Processing custom:

-

Support

-

Turbidity of inlet water:

-

500(mg/l)

-

Turbidity of effluent:

-

3(mg/l)

-

Material:

-

Carbon Steel / Stainless Steel

-

Application:

-

Solid-liquid Separation

-

Delievery time:

-

After get the deposit within 15 days

-

Usage:

-

wastewater pre-treatment

Product Details

Juntai dissolved air flotation is one of the most effective methods with a specific gravity close to that of water at 1.0. Juntai dissolved air flotation is a liquid/solid or liquid/liquid separation process to remove minute suspended matter, colloids, oils and greases with a density close to that of water.

Juntai dissolved air flotation is an innovation combining traditional dissolved air flotation concept and modern technology.

Dissolved air flotation (DAF)

is a clarification process that utilizes air to remove suspended matter from the surface of treated water. DAF works by dissolving air under pressure and then releasing millions of tiny air bubbles into the water at atmospheric pressure.

Advantages:

1.Total suspended solids (TSS) reduction up to 97%

2.Chemical oxygen demand (COD) removal up to 85%

3.

Low-cost operation and maintenance

4.

Standard and customized units meet a variety of application and flow ranges

5.Designed for ease of installation and use

6.Suitable for high-salinity water

Equipment Introduction

|

Model

|

Treatment capacity(m3/h)

|

Dissolved gas volume(m3/h)

|

Weight(T)

|

|

|

|

JTDAF-5

|

5

|

1—2

|

2.1

|

6.5

|

|

|

JTDAF-10

|

10

|

2—3

|

3.2

|

8.5

|

|

|

JTDAF-20

|

20

|

5—7

|

3.6

|

14.7

|

|

|

JTDAF-30

|

30

|

6—10

|

3.9

|

19.2

|

|

|

JTDAF-50

|

50

|

15—20

|

5.6

|

41

|

|

|

JTDAF-80

|

80

|

24—32

|

7.6

|

63

|

|

|

JTDAF-100

|

100

|

30—35

|

11.5

|

81

|

|

|

JTDAF-150

|

150

|

60—80

|

15

|

115

|

|

|

JTDAF-200

|

200

|

80—100

|

19

|

160

|

|

|

JTDAF-250

|

250

|

110—120

|

23

|

230

|

|

|

JTDAF-300

|

300

|

120—180

|

26

|

295

|

|

Working Principle:

Air flotation separation and purification mainly plays the role of solid-liquid separation (at the same time, it can reduce COD, BOD, chromaticity, etc.).

Air flotation mainly uses the micro bubbles in the dissolved air water generated by the dissolved air system to bond with the suspended flocs in the water, and the suspended matter rises to the water surface together with the micro bubbles to form flotsam, so that the suspended flocs in the water can be removed.

Application in Various Industry:

The aim of dissolved air flotation is to separate the fine suspended solids in water, algae and micro-floc. And dissolved air flotation can be used in the following industries:

1.Separate or recycle waste oil or grease in: oil exploration and refining, biodiesel, machining , food production and catering and so on.

2.High concentration organic wastewater treatment: paper, printing and dyeing, textile, leather, pharmaceutical, fermentation wastewater and so on.

3.Biochemical effluent liquid separation: the anaerobic effluent solid-liquid separation, aerobic (activated sludge process,contact oxidation, filter) biochemical water solid-liquid separation, the secondary settling tank Effluent treatment and

so on.

4.Farm and slaughter house wastewater treatment: cattle, pigs, chickens farm, slaughter house wastewater.

5.Manufacturing waste: electroplating, painting, etc.

6.Purification: river, landscape, recycle water and so on.

1.Separate or recycle waste oil or grease in: oil exploration and refining, biodiesel, machining , food production and catering and so on.

2.High concentration organic wastewater treatment: paper, printing and dyeing, textile, leather, pharmaceutical, fermentation wastewater and so on.

3.Biochemical effluent liquid separation: the anaerobic effluent solid-liquid separation, aerobic (activated sludge process,contact oxidation, filter) biochemical water solid-liquid separation, the secondary settling tank Effluent treatment and

so on.

4.Farm and slaughter house wastewater treatment: cattle, pigs, chickens farm, slaughter house wastewater.

5.Manufacturing waste: electroplating, painting, etc.

6.Purification: river, landscape, recycle water and so on.

Packaging Display

We use standard package. If you have special package requirements, we will pack as required.

Hot Searches