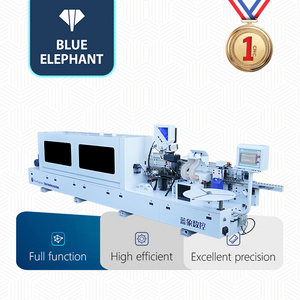

Two modes, one-button switching: partial bevel + straight edge , straight edge .

Application:

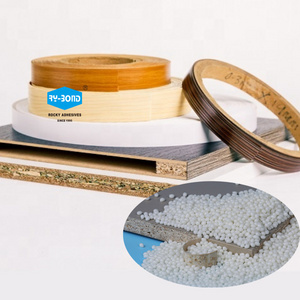

The machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, PVC edge banding, pure veneer edge banding, sandwich board, plywood etc, straight line edging and trimming. The machine is stable, reliable and durable, with favorable price. It is suitable for large and medium-sized furniture manufacturers.

The machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, PVC edge banding, pure veneer edge banding, sandwich board, plywood etc, straight line edging and trimming. The machine is stable, reliable and durable, with favorable price. It is suitable for large and medium-sized furniture manufacturers.