- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1000

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

WUMU

-

Place of Origin::

-

Shanghai China (Mainland)

-

Brand Name::

-

CISSCO

-

Model Number:

-

1438

-

Application::

-

dacron/terylene/non-woven fabrics

-

Main Products::

-

drafting machine,tighting hot styling,tractor,fiber spinning machine

Quick Details

-

Machine Type:

-

Polyester Staple Fiber for Pillow Filling Making Machine

-

Product:

-

Polyester Staple Fiber for Pillow Filling Making Machine

-

Material Capabilities:

-

FIBER

-

Weight (KG):

-

1000

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

WUMU

-

Place of Origin::

-

Shanghai China (Mainland)

-

Brand Name::

-

CISSCO

-

Model Number:

-

1438

-

Application::

-

dacron/terylene/non-woven fabrics

-

Main Products::

-

drafting machine,tighting hot styling,tractor,fiber spinning machine

Polypropylene Staple Fiber for Pillow Infilling Making Machine

1.Application

The PSF Production Line can be used to produce polyester, polypropylene, polyamide and other staple fiber .

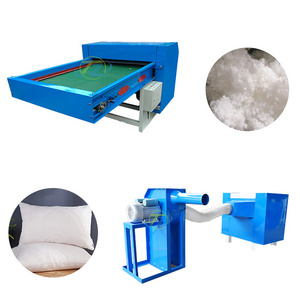

PET stable fibers have a variety of different uses: in the cotton spinning industry such as, singly spinning or spinning together with cotton along with, viscose, fiber, fur and vinyl. For instance, the clothing material for pillows. Also, they are widely used as shell fabric, packing cotton, filling material, thermal insulation materials and waterproof cotton.

Corresponding to technical equipment adjustment, it will be used to produce three-dimensional hollow fiber and other special chemical fiber. The mainframe is diveded into two main parts, the prevenient filature and post filature .

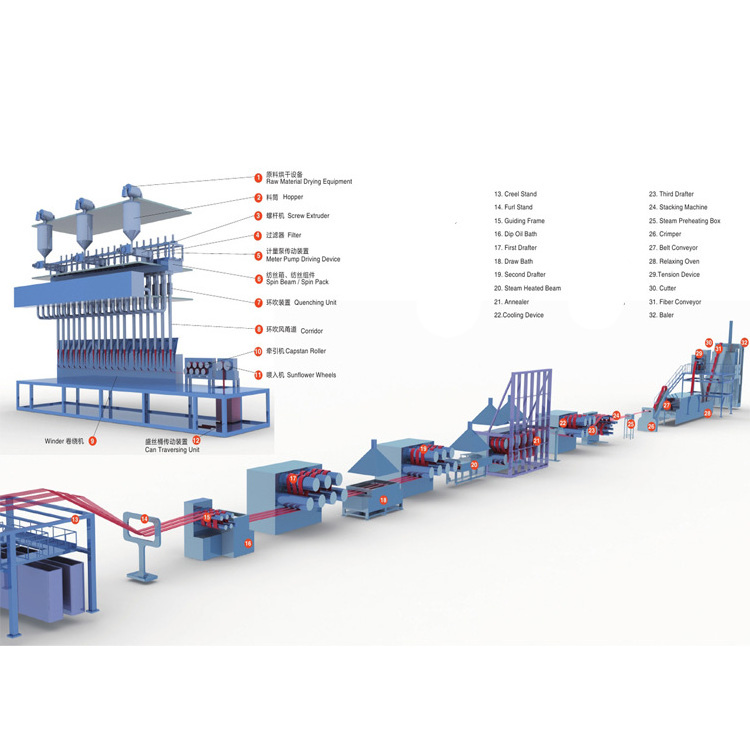

2. Processes

2.1. Fore Spinning Line

Vacuum Dryer -> Hopper -> Screw Extruder -> Filter -> Spin Beam (Meter Pump System, Spin Pack, Spinneret) -> Quenching Unit -> Interfloor Duct -> Draw-off Wall -> Capstan Roller -> Sunflower Gearing unit -> fiber can traverse system.

2.2. After Spinning Line

- if 2-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tow Stacker -> Crimper Steam Box -> Crimper -> Tow Conveyer -> Relaxer -> Tow Tension Stand -> Cutter -> Chain Plate Conveyor -> Baling Press

- if 3-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tension Control Device -> Tow Stacker -> Crimper Steam Box -> Crimper -> Silicon Oil Sprayer -> Tow Tension Stand -> Cutter -> Fiber Spreader -> Fiber Leveler -> Relaxer -> Chain Plate Conveying system -> Baling Pressrecycled psf production line

3. Pictures

Standard Package for Ocean Shipping