- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V 50-60HZ

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FUNLE

-

Dimension(L*W*H):

-

70X35X45CM

-

Weight:

-

63 KG

-

Applicable products:

-

High and low viscosity liquid and paste

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Machinery Capacity:

-

100BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V 50-60HZ

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FUNLE

-

Dimension(L*W*H):

-

70X35X45CM

-

Weight:

-

63 KG

-

Applicable products:

-

High and low viscosity liquid and paste

-

Marketing Type:

-

Hot Product 2022

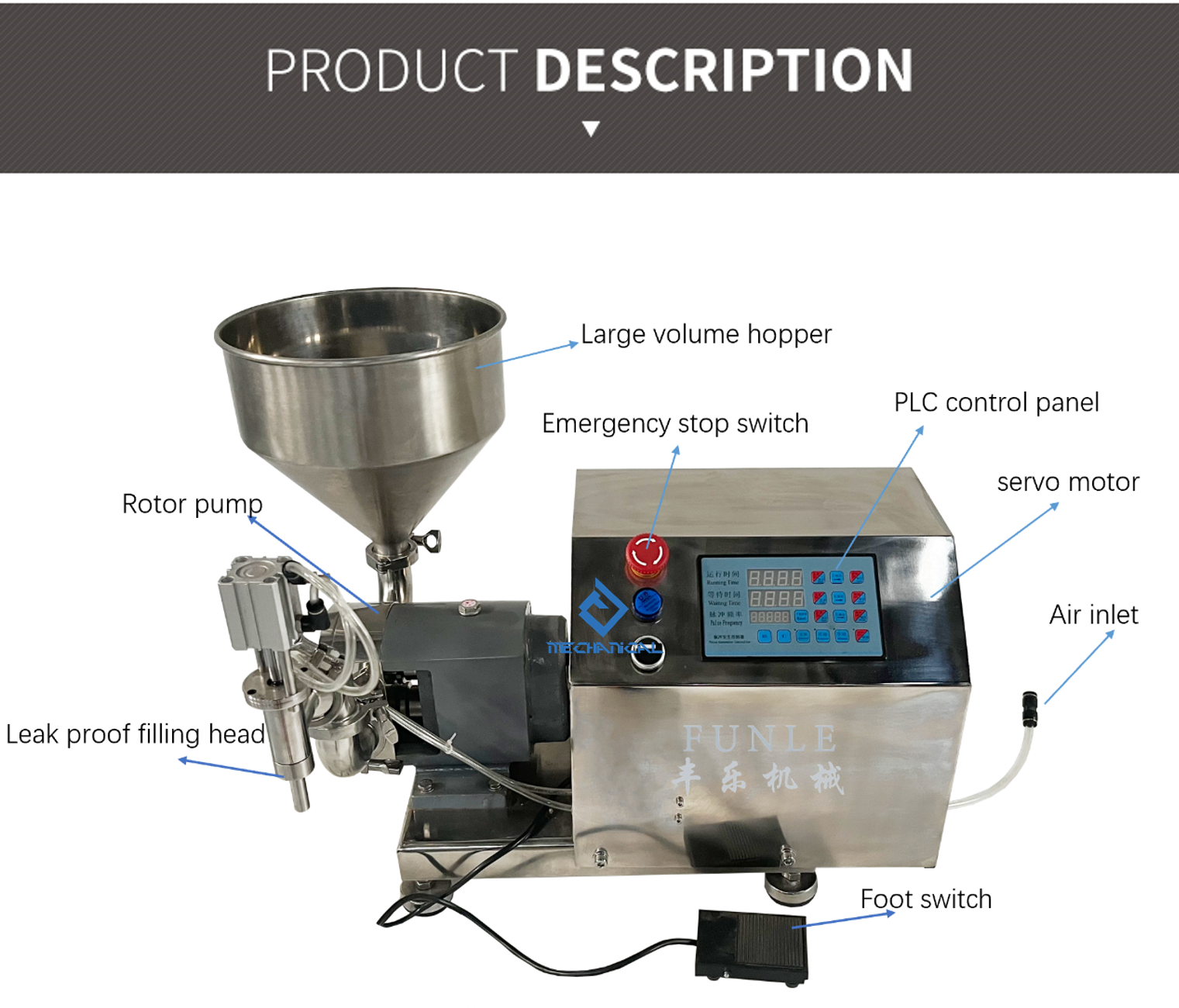

working principle

Stainless steel rotor type high viscosity filling machine is a kind of high viscosity and high fluidity material filling machine developed by our company. It is based on the principle of servo motor drive and material delivery through double cam rotor.

The speed of the rotor is controlled by the PLC control panel to control the valve speed to adjust the filling amount and filling speed.

So as to achieve the one-time filling of high efficiency, high capacity and high viscosity products.

The equipment has the characteristics of simple and reasonable structure, convenient operation and high precision.

The equipment has the characteristics of simple and reasonable structure, convenient operation and high precision.

|

Product name:

|

stainless steel high viscosity filling machine

|

|

Machine model:

|

FL-ZB3A-6

|

|

Filling range:

|

5-50000ML

|

|

Filling speed:

|

45-60 bottles/minute

|

|

Filling materials:

|

liquid, paste, high viscosity fluid

|

|

Product characteristics:

|

Quantitative subpackage, servo motor drive, accurate filling

|

|

Product material:

|

SUS304 stainless steel

|

|

Customized products:

|

products can be customized according to your requirements

|

Application:

This equipment is mainly applicable to the ideal filling equipment for food, daily chemical, pesticide, medicine and special industries. It has the advantages of accurate filling, fast filling, one-time filling of large capacity bottles, convenient cleaning, etc.

This equipment is mainly applicable to the ideal filling equipment for food, daily chemical, pesticide, medicine and special industries. It has the advantages of accurate filling, fast filling, one-time filling of large capacity bottles, convenient cleaning, etc.

Related Products

1. About Delivery term

Q: What's the delivery term for doing business with you?

A: EXW/FOB/CIF/DDU… it depends on preference of clients.

2. About Lead time

Q: What's the leading time after placing order?

A: After getting your confirmation, mixing tank about 25 days, pump 15 days, colloid mill 10 days. However, it depends on

production schedule is in slack or peak season, and the complication of machines.

3. About Payment time

Q: What's the payment term?

A: T/T 40% as down payment, 60% balance payment before delivery.

4. About Quality

Q: How do you control your quality?

A: All machines before delivery will be tested and send video for customer, if no problem then arrange balance payment.

Meanwhile,CE is available for customers' needs.

5. About Packing

Q: How do you pack the machines?

A: Standard export wooden case, to avoid damage during delivery.

6. About Customized

Q: Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings.

Q: What's the delivery term for doing business with you?

A: EXW/FOB/CIF/DDU… it depends on preference of clients.

2. About Lead time

Q: What's the leading time after placing order?

A: After getting your confirmation, mixing tank about 25 days, pump 15 days, colloid mill 10 days. However, it depends on

production schedule is in slack or peak season, and the complication of machines.

3. About Payment time

Q: What's the payment term?

A: T/T 40% as down payment, 60% balance payment before delivery.

4. About Quality

Q: How do you control your quality?

A: All machines before delivery will be tested and send video for customer, if no problem then arrange balance payment.

Meanwhile,CE is available for customers' needs.

5. About Packing

Q: How do you pack the machines?

A: Standard export wooden case, to avoid damage during delivery.

6. About Customized

Q: Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings.

Hot Searches