- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TG01

-

Name:

-

Rotary Shaft Oil Seal Crankshaft Oil Seal 45*62*8

-

Color:

-

brown

-

Hardness:

-

20~90 Shore

-

Temperature:

-

-40~260

-

Application:

-

Autos

-

Service:

-

Custom shaft seal

-

Style:

-

TC TG

-

Other Name:

-

80*125*12 oil seals

Quick Details

-

Size:

-

45*62*8, 45*62*8

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

SVKS

-

Model Number:

-

TG01

-

Name:

-

Rotary Shaft Oil Seal Crankshaft Oil Seal 45*62*8

-

Color:

-

brown

-

Hardness:

-

20~90 Shore

-

Temperature:

-

-40~260

-

Application:

-

Autos

-

Service:

-

Custom shaft seal

-

Style:

-

TC TG

-

Other Name:

-

80*125*12 oil seals

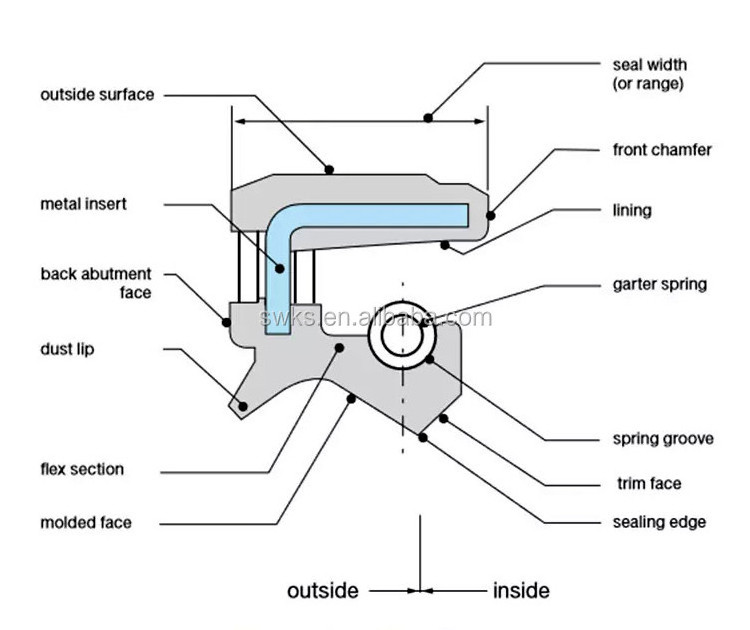

Product Description

|

Product Name

|

Rotary Shaft Oil Seal Crankshaft Oil Seal 45*62*8

|

|

Material

|

Rubber + Stainless Steel...etc

|

|

Color

|

Brown green red black color

|

|

Dimension(mm)

|

05*16*06mm—1600*1650*25mm or Customized

|

|

Temperature Resistance

|

-30~+120℃

|

|

Pressure Range

|

0-0.5MPA

|

|

Speed

|

25m/s

|

Product Features:

Rotary Shaft Oil Seal Crankshaft Oil Seal 45*62*8

- High quality raw material, dust-proof, water-proof, oil-proof

- Excellent durability in using and good sealing effect

- Wear resistance, long service life

- Show stable in high speed rotation.

- High quality raw material, dust-proof, water-proof, oil-proof

- Excellent durability in using and good sealing effect

- Wear resistance, long service life

- Show stable in high speed rotation.

Product Application

It is widely used in crankshafts, camshafts, differentials, shock absorbers, engines, axles, front and rear wheels of automobiles and motorcycles.

Production Process

Material Inspection:

Storage of all raw materials before the test, and issue a report on the corresponding material

properties,compared with raw material's own property report, two reports property values is consistent, can put in storage.

Model Inspection: After the mold development or mold cleaning finished on the machine, we will test all the specifications of the mold to ensure that each cavity of the product specifications and quality.

Production Inspection: The production process of the product inspection personnel timing semi-finished product inspection, ensure the quality of the rationality of technology, defective rate control in a reasonable range.

Quality Control: The quality inspection department will conduct a sampling inspection of each batch of products

Production Full Inspection:The optical inspection machine can ensure the appearance and dimension of the product are

100%qualified.

properties,compared with raw material's own property report, two reports property values is consistent, can put in storage.

Model Inspection: After the mold development or mold cleaning finished on the machine, we will test all the specifications of the mold to ensure that each cavity of the product specifications and quality.

Production Inspection: The production process of the product inspection personnel timing semi-finished product inspection, ensure the quality of the rationality of technology, defective rate control in a reasonable range.

Quality Control: The quality inspection department will conduct a sampling inspection of each batch of products

Production Full Inspection:The optical inspection machine can ensure the appearance and dimension of the product are

100%qualified.

Our Services & Strength

1.Professional spare parts service.

2.A lot of standard sizes in stock.

3.Custom spare parts service.

4.Free samples available.

5.Sealing system design.

6.Fast delivery

2.A lot of standard sizes in stock.

3.Custom spare parts service.

4.Free samples available.

5.Sealing system design.

6.Fast delivery

Packing&Shipping

Inner package: Plastic bag , outer package: carton box Outer package: carton box or paper package

Shipment: we could ship by air , by express, by sea or as client requirements

Lead time: within 5-7 working date for stock products

Mold production: within 12-15 working date

PE bag inside, Carton outside, then Pallet. All packaging are signed our logo. If any customized request, welcome.

Shipment: we could ship by air , by express, by sea or as client requirements

Lead time: within 5-7 working date for stock products

Mold production: within 12-15 working date

PE bag inside, Carton outside, then Pallet. All packaging are signed our logo. If any customized request, welcome.

Different Types Shows

Contact Us

Hot Searches