- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TEREK

-

Model Number:

-

LU-LDD-300

-

Structure:

-

Stainless steel frame

-

Power supply:

-

Air driven

-

Pressure Source:

-

TEREK fluid booster pump

-

Pump principle:

-

Pneumatic Reciprocating

-

Outlet pressure Control:

-

Drive air regulator valve

Quick Details

-

Warranty:

-

24 months

-

Power:

-

Hydraulic

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TEREK

-

Model Number:

-

LU-LDD-300

-

Structure:

-

Stainless steel frame

-

Power supply:

-

Air driven

-

Pressure Source:

-

TEREK fluid booster pump

-

Pump principle:

-

Pneumatic Reciprocating

-

Outlet pressure Control:

-

Drive air regulator valve

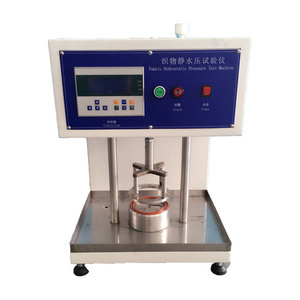

Product Description

The TEREK Pneumatic hydraulic test bench uses pure compressed air as the driving power source, liquid booster pump as the pressure source, and water, hydraulic oil and other liquid as the pressurized medium. The output pressure is proportional to the driving gas pressure. By adjusting the pressure of the driving gas source, the corresponding pressure of the pressurized liquid can be obtained. When the pressure of the driving source is balanced with that of the pressurized liquid, the pneumatic booster pump will be automatically stops and the output liquid pressure is stabilized at the preset pressure. Therefore, it has the features of explosion-proof, energy saving, environmental protection, adjustable output pressure, small volume, light weight, simple operation, reliable performance and wide application range.

The fluid pressurized control cabinet has been equipped with the fluid booster pump, the drive air water filter, the pressure regulator valve, pressure gauges and manual pressure relieve valve. The main parts of the equipment are assembled in closed stainless steel cabinet or stainless steel frames. The pressure gauge, valve and pressure regulator will be mounted on the panel. The corresponding sign will also be marked on the panel.

The ideal working high pressure can be achieved by adjusting the driving air pressure. When the driving air pressure and output pressure are balanced, the pump will automatically stop the filling pressure, and the output pressure will remain at the preset value.

The hydraulic device can be used for pressure testing of various components, research and testing institutions and industrial pressure field. Booster pump have a variety of pressure ratios, these series of pumps are ideal choice for various hydraulic power operations. The maximum operating pressure up to 640Mpa. The structural design of the fluid pressurized control cabinet are compact. And according to the special requirement of customers, the air driven fluid booster pumps, valves, control switches and other precision accessories are assembled in the frame or closed cabinet. The pump will stop working automatically when the output pressure reaches the preset value. The pump will start automatically when the outlet pressure drops slightly or the air drive pressure increases.

Product parameters

TEREK pumps feature is a large air piston joint to a smaller diameter piston. The pressure ratio is the difference of these two areas and is the method of determining maximum outlet pressure. Higher pressures obtained by using higher pressure ratios. TEREK model reflect the pumps nominal pressure ratios, while the technical data indicates exact ratios. The outlet pressure is easily to set through a simple regulator. By multiplying the pressure ratio by the available shop air pressure, the nominal liquid pressure can be calculated. Basically the principle of operation is similar to a reciprocating amplifier where control of the piston at the end position is reciprocating. The automatic reciprocating motion of the piston is controlled by a built-in four-way valve. TEREK pumps are air driven at a drive air pressure of 3 to 8 bar (29 to 116 psi) by the normal air compressor.

Refer to model technical parameters.

Refer to model technical parameters.

|

Product name |

Pneumatic liquid booster pump h ydrostatic pressure testing bench |

|

Model |

LU-L DD-100 |

|

Pressure ratio |

100:1 |

|

Medium |

Hydraulic oil or water |

|

Drive air source pressure |

3-8bar. |

|

Power source |

TEREK liquid booster pump |

|

Maximum liquid outlet pressure |

800 bar / 11600 psi. |

|

When adjusting drive pressure to 5.0 bar |

The high output pressure is 500 bar / 7250 psi |

|

When adjusting drive pressure to 6.9 bar |

The high output pressure is 690 bar / 10000 psi |

|

Outlet pressure control unit |

Drive air regulator va l ve |

|

Pressure control accuracy |

Less than 1%F.S; |

|

Pressure measurement accuracy |

± 0.4% FS pressure gauge |

|

Valves and piping |

High pressure needle valve and stainless steel piping |

|

Equipment f rame type |

304 Stainless steel frame |

|

Equipment weight |

3 8 KG |

|

Export wooden case weight |

4 4 KG |

|

Equipment d imension |

500*370*520 mm |

|

Packing size |

560*450*570 mm |

|

Connection size(inch) Outlet |

NPT 1/4 Internal Thread |

|

Production time |

1 2-15 working days. |

Detailed Images

Packaging picture

Packaging picture

System configuration

The liquid booster pump mainly consists of air drive chamber, pressurizing chamber, auto reversing valve, inlet check valve, outlet check valve, high quality sealing parts, air drive piston, pressurizing piston, silencer etc. TEREK hydraulic test bench system mainly includes three sets of air driven liquid booster pump, 15L water tank, pressure gauges, liquid filter, air filter, air regulating valve, control valves, pipelines, cabinet, pressure release valve etc. The main parts of the equipment are assembled in closed stainless steel cabinet or stainless steel frames. The pressure gauge, valve and pressure regulator will be mounted on the panel. The corresponding sign will also be marked on the panel.

Product advantages:

1. Equipped with high quality pneumatic liquid booster injection pump, it can easily achieve any adjustable and controllable output pressure and flow.

2. The contact liquid section is stainless steel, strong corrosion resistance, suitable for a variety of chemical reagents;

3. It can be used at various levels of wellhead pressure, the pressure system has control function.

4. Chemical reagent injection system output pressure is high. The output pressure can be adjusted through the pressure regulating valve, the system has to stop working under the set pressure;

5. Advanced technology, reasonable structure design. The features of small size, light weight, beautiful appearance;

6. By air/gas driven, no need to use electricity, there will be no spark generated, safe explosion-proof;

Packaging & Shipping

Our Services

1. We'd like to provide our professional advice regarding machines, materials, packing and market for this product.

2. We'd like to customize special machine according to customer's request.

3. We'd like to help our customers for booking ship as customer request.

5. Operation manual will be provided after shipment.

6. We provide one year warranty.

7. Free wearing parts will be sent together with the machine.

8. Working video of the machine will be sent to you accordingly to your need.

All equipment and accessories are guaranteed for one year. Our sales staff and technical department provide permanent technical advice and operation guidance. If you have any questions about the operation of the equipment, please turn off the air source and equipment, check the instructions in time or contact the sales and service personnel. Thanks.

Equipment inventory and workshop

FAQ: