- Product Details

- {{item.text}}

Quick Details

-

Max. Weight of Workpiece(kg):

-

1000

-

Spindle Bore(mm):

-

150

-

Width of bed (mm):

-

1250 mm

-

Spindle Motor Power(kW):

-

18.5

-

Max. Turned Length (mm):

-

1000

-

Travel (X Axis)(mm):

-

1000 mm

-

Travel (Z Axis)(mm):

-

1000 mm

-

Place of Origin:

-

Guangxi, China

-

Dimension(L*W*H):

-

2200x2224x2396mm

-

Brand Name:

-

XIASHI

-

Model Number:

-

CK5112

-

Voltage:

-

380V

-

Weight (KG):

-

8000

-

CNC or Not:

-

CNC

-

Machine Type:

-

Lathe Machine CNC

-

Product name:

-

CNC Lathe Mechine

-

Name:

-

Metal Cnc Lathe

-

Keyword:

-

Automatic CNC Lathe Machine

-

Function:

-

Machining Metal

-

After-sales Service Provided:

-

Online Support

-

Product type:

-

Economical CNC Lathe

-

Precision:

-

High Precision Machine

-

Automatic Grade:

-

Automatic CNC Turning Machine

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

1

-

Max. Spindle Speed (r.p.m):

-

200 r.p.m

-

Max. Weight of Workpiece(kg):

-

1000

-

Spindle Bore(mm):

-

150

-

Width of bed (mm):

-

1250 mm

-

Spindle Motor Power(kW):

-

18.5

-

Max. Turned Length (mm):

-

1000

-

Travel (X Axis)(mm):

-

1000 mm

-

Travel (Z Axis)(mm):

-

1000 mm

-

Place of Origin:

-

Guangxi, China

-

Dimension(L*W*H):

-

2200x2224x2396mm

-

Brand Name:

-

XIASHI

-

Model Number:

-

CK5112

-

Voltage:

-

380V

-

Weight (KG):

-

8000

-

CNC or Not:

-

CNC

-

Machine Type:

-

Lathe Machine CNC

-

Product name:

-

CNC Lathe Mechine

-

Name:

-

Metal Cnc Lathe

-

Keyword:

-

Automatic CNC Lathe Machine

-

Function:

-

Machining Metal

-

After-sales Service Provided:

-

Online Support

-

Product type:

-

Economical CNC Lathe

-

Precision:

-

High Precision Machine

-

Automatic Grade:

-

Automatic CNC Turning Machine

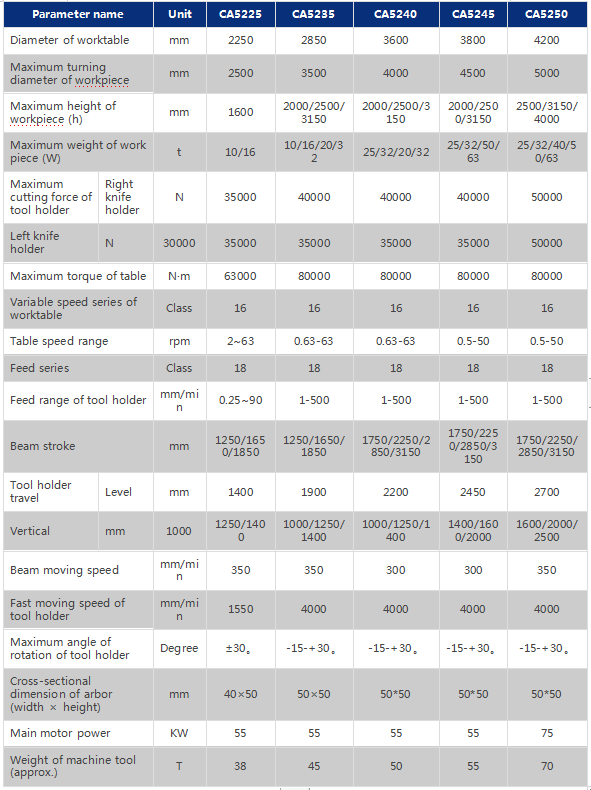

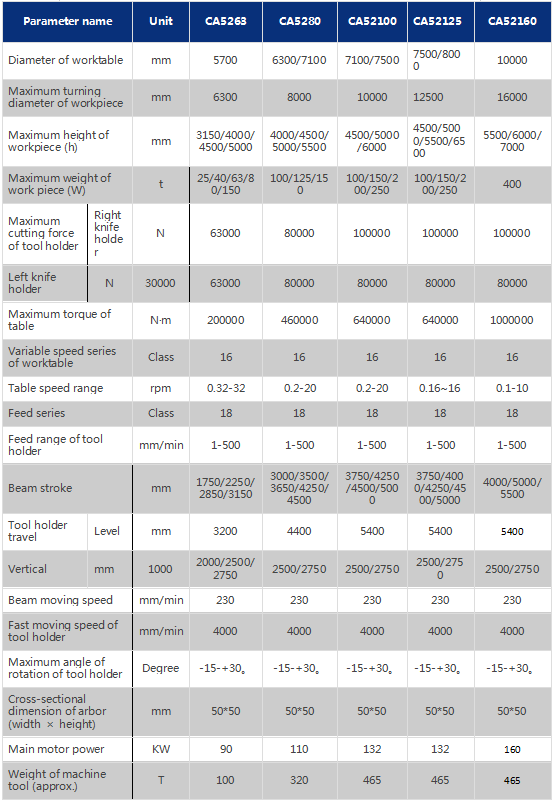

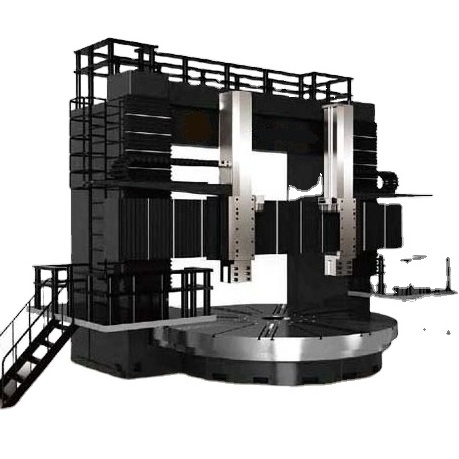

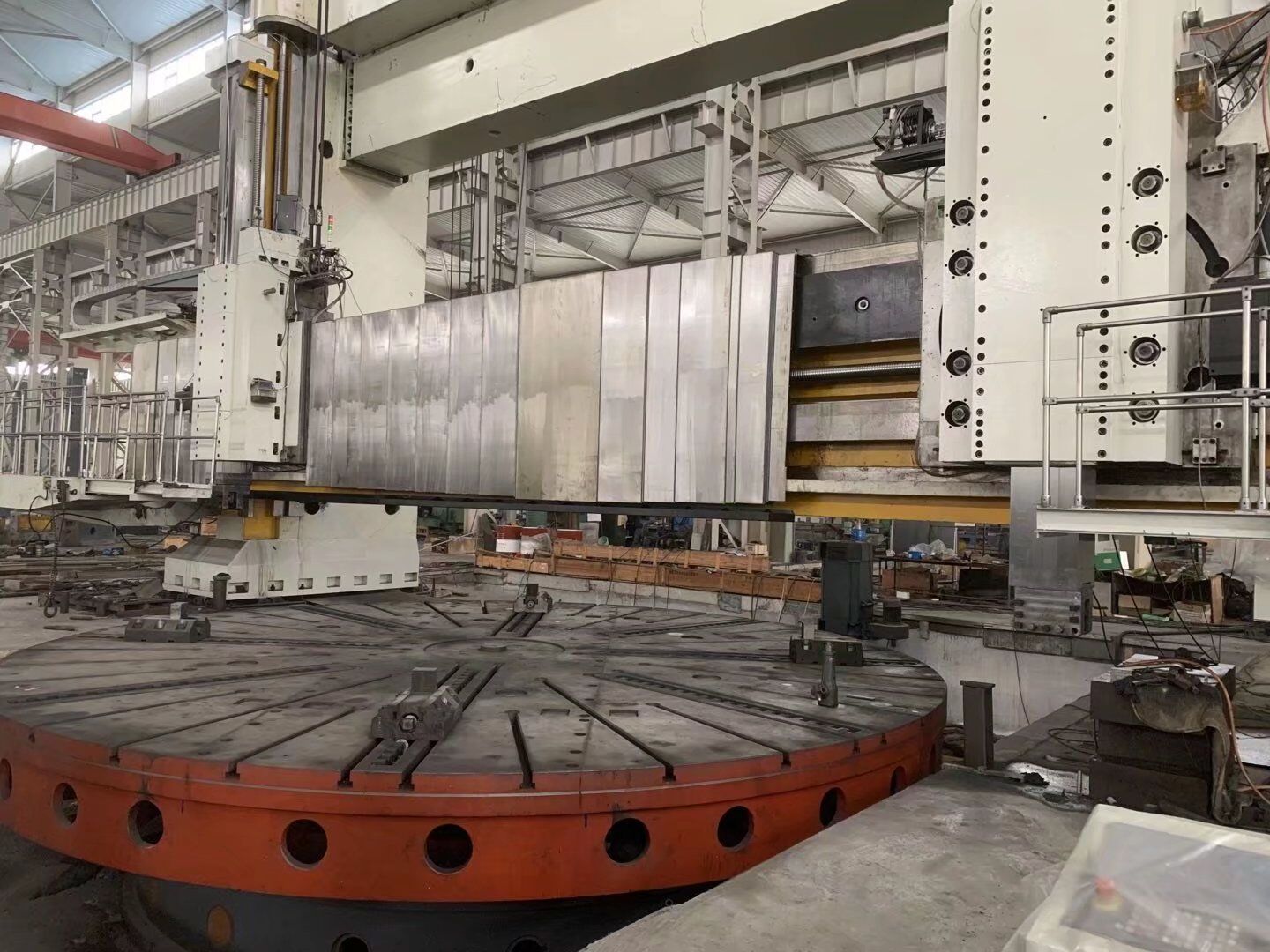

Vertical lathe is mainly used for machining all kinds of rotary body surface (inner and outer cylindrical surface, conical surface, rotary body forming surface, etc.) , rotary body end face and Hole, but also processing external threads and internal threads. Vertical cars are widely used in machinery factories. Model: CA5225 series, CA5235 series, CA5240 series, CA5245 series, CA5250 series, CA5263 series, CA5280 series, CA52100 series, CA52125 series, CA52160 series, category: Ordinary Vertical car C52 series

Product description:

There are many kinds of standing cars, according to its structure and use, it is mainly divided into horizontal lathe, vertical lathe, floor lathe, turret lathe, single-spindle and multi-spindle automatic lathe, semi-automatic lathe, profiling and multi-tool lathe, turn lathe, CNC lathe and turning center. In addition, there are a variety of specialized lathes, such as crankshaft lathes, camshaft lathes and fork lathe. In a large number of production also made district special yu lathes, especially enzyme lathes so that Yu is the most common.

In an upright car, in order to get the desired motion, the actuators and the power source, or the actuators and actuators, need to be connected through a series of actuators. A series of transmission elements forming a transmission link is called a transmission chain. There are two kinds of transmission mechanisms in the transmission chain: one is fixed transmission ratio and transmission direction of the transmission mechanism, such as fixed ratio gear pair, worm gear pair, screw and nut pair, known as fixed ratio transmission mechanism; The other type is the transmission mechanism which can change the transmission ratio and transmission direction according to the processing requirement, such as the exchange gear transmission mechanism, the sliding gear transmission mechanism, the clutch transmission mechanism and so on. Transmission chain (motion chain) can also be divided into internal and external contact two.

(1) the outer linkage transmission chain is the transmission chain connecting the power source and the vertical train actuators. It enables the actuator to obtain a predetermined speed of motion, and transfer a certain amount of power. The change of the transmission ratio of the external linkage transmission chain only affects the productivity or the wheat surface roughness, and does not affect the formation of the workpiece surface shape.

(2) in order to combine the motion of two or more units, the transmission link between the actuator and the actuator is called Inner Link. A series of transmission elements that form an internal linkage is called an internal linkage transmission chain. The relative velocity (and relative displacement) between the actuators should be strictly required, otherwise, the correct motion trace can not be guaranteed. Therefore, in the internal transmission chain, the transmission ratio of each transmission pair must be accurate, there should be no friction transmission and instantaneous transmission ratio changes of the transmission parts. When thread turning tool is used on vertical lathe, the thread transmission chain between the spindle and the tool holder is an internal link transmission chain with strict transmission ratio, which can guarantee the distance needed by the thread.

Double-column vertical car has two tool holders, widely used in metallurgy, chemical, electrical, mining, shipping, steel, military and other industries in large-scale workpiece machining. This series of machine tools is suitable for carbide and ceramic cutting tools, such as Ferrous, Non-ferrous metal and some non-metallic parts of the internal and external cylindrical surface, internal and external conical surface, end face, groove rough finishing. FEED adopts AC servo motor drive, ball screw drive. The main drive of C52 series of common vertical car is driven by AC motor and stepless speed-changing mechanism, which can realize the speed range of worktable. DC motor can also be selected according to the special requirements of users. Main Drive: two-stage mechanical transmission and three-stage speed regulation. The worktable is of thermal symmetry structure. The worktable spindle adopts high precision adjustable radial clearance double row short cylindrical roller bearing centering. Transverse hydrostatic guide rail is adopted in axial direction. The worktable has the characteristics of high rotating precision, large bearing capacity and small thermal deformation.

Main components technical performance:

1. High precision, worktable spindle bearings using double row roller bearings and flat bearing worktable constant flow hydrostatic guide rail.

2. The main parts of gantry frame, such as left and right column, cross beam, Ram and worktable, are optimized by CAD. According to the standard of vertical lathe steel, the optimized section size, structure and shape are symmetrical, it is a machine tool with static and dynamic stiffness, small thermal deformation and so on.

3. Long service life due to the large size of the table guide rail, when the work weight is fixed, the static pressure guide rail bearing area is large, strong anti-eccentric load capacity, static oil pressure is small, so that the table has a high service life.

Main functions:

Vertical lathe is mainly used for machining all kinds of rotary body surface (inner and outer cylindrical surface, conical surface, rotary body forming surface, etc.) , rotary body end face and Hole, but also processing external threads and internal threads. In the machinery manufacturing plant, the use of vertical vehicles is very wide, in the technical cutting machine tool accounted for the largest proportion.

Vertical lathes use mainly turning tools, many lathes can also use the drill, Reamer, Reamer, tap, die and other hole processing tools and thread tools processing. The machining motion is generally the rotary motion of the workpiece, and the feed motion is accomplished by the straight-line movement of the tool.

Product parameters: