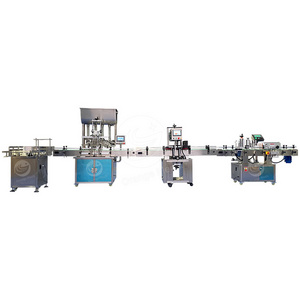

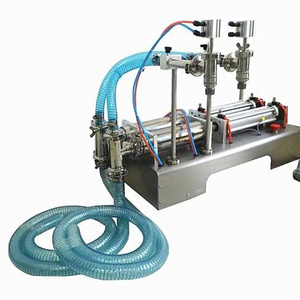

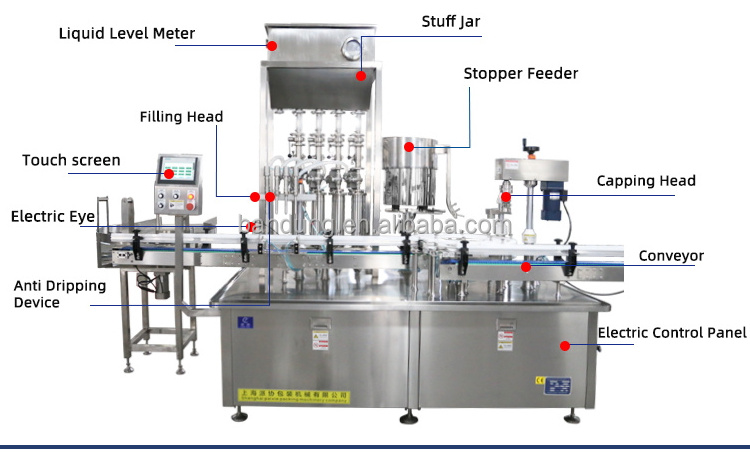

This filling machine could be linear tor rotary type which is designed according to customers capacity and filling volume. It suits different size of plastic and glass bottles, and the height of the filling nozzles is adjustable. The filling nozzles are made of SS304 or 316, resist high temperature filling. drip-proof , via photoelectric detection to ensure no bottle no filling. Widely used for liquid and paste filling. Also can be customized for other types of filling based on customer requirement.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220/380V 50/60Hz

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Xiepai

-

Dimension(L*W*H):

-

1600*1500*1800mm

-

Weight:

-

400 KG

-

Keywords:

-

Paste Jam Filling Capping Machine

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Filling range:

-

100-5000ml

-

Filling nozzles:

-

Customized Nozzle

-

Cap type:

-

Screwing/Crimping/Pressing

-

Marketing Type:

-

Other

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Wooden Case

-

Filling Material:

-

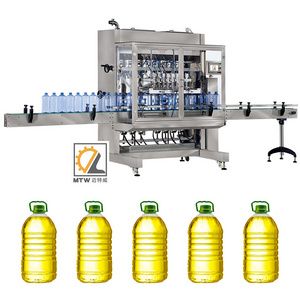

Beer, Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220/380V 50/60Hz

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Xiepai

-

Dimension(L*W*H):

-

1600*1500*1800mm

-

Weight:

-

400 KG

-

Keywords:

-

Paste Jam Filling Capping Machine

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Filling range:

-

100-5000ml

-

Filling nozzles:

-

Customized Nozzle

-

Cap type:

-

Screwing/Crimping/Pressing

-

Marketing Type:

-

Other

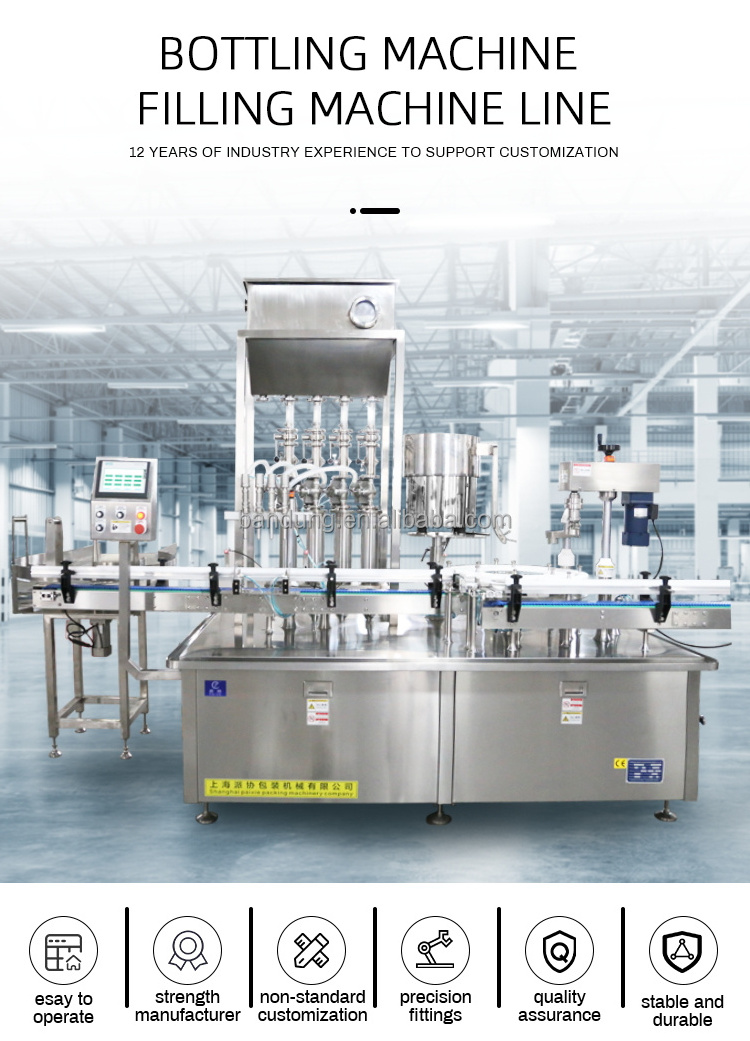

Products Description

The most widely used filling machine in small to big bottle filling operations because it handles a wide range of

liquids at a modicum of cost. Ease of cleaning, ease of setup and expandable output makes this machine a favorite of growing companies. Used for free flowing liquids with very small to no particulates, it is adept in foam control and often used in fill-to-level glass applications.

Features:

1, Simple structure, convenient maintenance, reliable drive.

2, Import FESTO cylinder and pneumatic components, guarantee the reliability of the machine.

3, High measurement accuracy, no drip phenomenon.

4, Filling speed, can automatic uninterrupted filling.

5, Adopt imported 316L stainless steel materials, inside and outside polishing, conforming to GMP standards.

Wide Range of Applications

Parameter

|

Model

|

XP-4

|

XP-6

|

XP-8

|

||

|

Capacity

|

3000-4200BPH

|

4200-5400BPH

|

5400-7000BPH

|

||

|

Bottle Volume

|

10-1000ml

|

10-1000ml

|

10-1000ml

|

||

|

Machine power

|

1.5KW

|

2.2KW

|

3.7KW

|

||

|

Bottle diameater

|

50-110mm

|

|

|

||

|

Bottle high

|

50-200mm

|

|

|

||

|

Bottle Type

|

PET / PE / PP / Glass / Metal

|

|

|

||

|

Bottle Shape

|

Round / Square / Unique Shape

|

|

|

||

|

Capping Type

|

Screw, Pressing, Crimping, etc

|

|

|

||

|

Driving Motor

|

Servo Motor

|

|

|

||

|

Machine Frame Material

|

SS304

|

|

|

||

Product Paramenters

MONOBLOCK LIQUID FILLING MACHINE

Conveyor belt mechanism

Adjust the clearance of the bottle blocking plates according to the diameter of the bottle in order to make bottles be conveyed

smoothly.Generally, it shall be 1~2 mm larger than the bottle diameter.

smoothly.Generally, it shall be 1~2 mm larger than the bottle diameter.

The height and the clearance of the filling needle tube shall be adjusted according to the height and size of the bottle.When the

bottle is transported to the bottom of the needle tube by the main turntable,the filling head is driven by the lifting cam in the

machine frame to go up and down, so that the needle tube inserts into the bottle for filling.

bottle is transported to the bottom of the needle tube by the main turntable,the filling head is driven by the lifting cam in the

machine frame to go up and down, so that the needle tube inserts into the bottle for filling.

Adjust the mechanical pressure regulator on the side plate of the machine so that caps can be transported to the fixed position of

cap pressing.

cap pressing.

1.Easy cleaning

2.No need tools to clean the pistons which gurantee the food grade,save time and labor.

3.CIP system is for option

Shanghai Xiepai Machinery Equipment Co.,Ltd is a professional manufacturer of filling line for over 12 years, customized filling lines for different industry customers like food and beverage, cosmetic, chemical industry and etc, lots of successful cases for your reference. The full automatic liquid filling machine is designed for saving time on adjusting and testing machine, it can fill liquid or paste accurately by entering a certain filling volume. The PLC control method makes it easy to operate and thigh speed working efficiency is ideal for different scale production. It can work with the automatic capping machine and labeling machine and other equipment based on customer requirement. XIEPAI filling line is widely used in the following industries:

* Beverage Filling Machine Line (such as water, juice, beer, liquor, vodka, wine etc.)

* Food Filling Machine Line (such as honey, sauce, oil, chocolate, vinegar etc. )

* Chemical Filling Machine Line (such as syrup, eye drop, alcohol, reagent, ampoul, syringe etc. )

* Cosmetics Filling Machine Line (such as perfume, body spray, nail polish, cream, lotion, detergent, hand gel etc. )

* Beverage Filling Machine Line (such as water, juice, beer, liquor, vodka, wine etc.)

* Food Filling Machine Line (such as honey, sauce, oil, chocolate, vinegar etc. )

* Chemical Filling Machine Line (such as syrup, eye drop, alcohol, reagent, ampoul, syringe etc. )

* Cosmetics Filling Machine Line (such as perfume, body spray, nail polish, cream, lotion, detergent, hand gel etc. )

A Series Of Installation And Technical Guide Videos, Easy To Learn

Hot Searches