- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Variable, Hydraulic

-

Weight:

-

100 KG

-

Dimension(L*W*H):

-

Standard Size

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

stainless steel

-

Structure::

-

Flexible Cylinder

-

Application:

-

Milk

-

Name:

-

Milk Production Machinery

-

Raw material:

-

Fresh Liquid Milk

-

Final product:

-

Drinking Milk

-

Product name:

-

heating and cooling tank

-

Processing:

-

Heating + Pasteurizing +cooling

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

OHFU

-

Voltage:

-

220V/380V

-

Power:

-

Variable, Hydraulic

-

Weight:

-

100 KG

-

Dimension(L*W*H):

-

Standard Size

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

stainless steel

-

Structure::

-

Flexible Cylinder

-

Application:

-

Milk

-

Name:

-

Milk Production Machinery

-

Raw material:

-

Fresh Liquid Milk

-

Final product:

-

Drinking Milk

-

Product name:

-

heating and cooling tank

-

Processing:

-

Heating + Pasteurizing +cooling

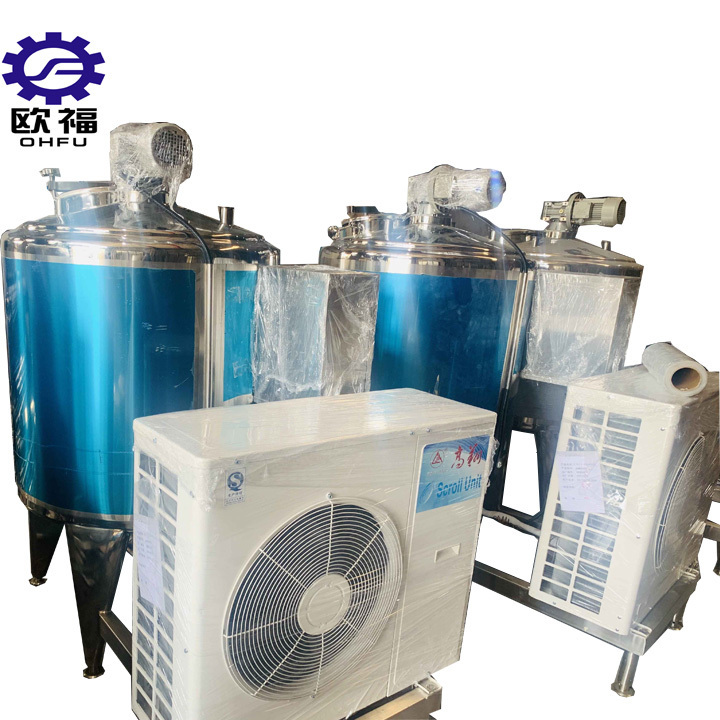

Milk Chilling Machine For Cow Dairy Farm Small Milk Processing Machine/Mini Milk Processing Plant

300L milk cooling tank specification

|

Capacity |

300L |

|

Material |

304 SS |

|

Shape and Orientation |

Vertical , cylindrical |

|

Thickness of inner shell |

2.5mm |

|

Thickness of outer shell |

1.2mm |

|

Thickness of insulation |

50mm |

|

Number of Agitator |

1 |

|

RPM of Agitator |

36 |

|

Washing /CIP cleaning |

cleaning ball |

|

Compressor Brand |

Copeland from US |

|

Size Compressor |

3P |

|

Number of Condensers |

1 |

|

Number of fans |

1 |

|

Type of refrigeration |

R22 |

|

Thermal insulation material |

polyurethane foaming liquid |

|

Refrigerating capacity |

6000 kcal / h |

|

Insulation performance (temperature) |

< 1 ℃ / 3H |

|

Agitator power |

0.75kw |

|

Voltage |

380V 50HZ 3phase (can be customized ) |

cooling tank (also named aging tank) has the advantage s of

energy saving, s ound disappearing , corrosion resistance, strong capacity

and convenient cleanin g. Widely used in d airy, food, pharmaceutical,

chemical, beverage and other i ndustr ies. The machine has the functions

of heating, cooling, heat preservation, sterilization or s lurry storage . It is

especially suitable for pasteurization and heat preservation of milk and it is the necessary equipment for ice cream production line . The equipment

consists of a reservoir solution, a cycloid planetary reducer , a stirring

blade and a 0 ℃ -100 ℃ thermometer, ect.

The classification of cooling tank

By the heating medium can be divided into: natural gas hot and cold tank, steam h ot and cold tank , electric heating h ot and cold cylinder . By the material in and out of the points can be divided into: open type hot and cold tank , enclosed type

hot and cold tank. By the structure can be divided into: regular type , taper from top to bottom type , head up and down

type.

The structure and function of the Heating and cooling tank :

Heating and cooling tank chart

Construction: interior, jacket, insulation layer, the outer foreskin, reducer, stirring blade, a thermometer and so on.

Liner: 304 stainless steel material, surface finish. Middle Jacket: The A3

teel plate or 1Cr18Ni9Ti made to strengthen the circle spiral devices, cold water from the bottom up (no pressure) to achieve the best lift and

cooling purposes.

Insulation group: stainless steel plate into a fish-scale pattern made of polyurethane or glass wool insulation layer to keep the temperature and the outside world, to achieve the insulation effect.

Reducer: cycloid planetary reducer, fixed to the beam of the bracket, reducer wheel shaft and impeller connection, the use of loop connection for easy disassembly and cleaning.

Thermometer: Specifications 00C ~ 1000C, installed on the beam, minimum for straight medium, the liquid material used in the lowest position can indicate the temperature and aging to achieve sterilization purposes.