- Product Details

- {{item.text}}

Quick Details

-

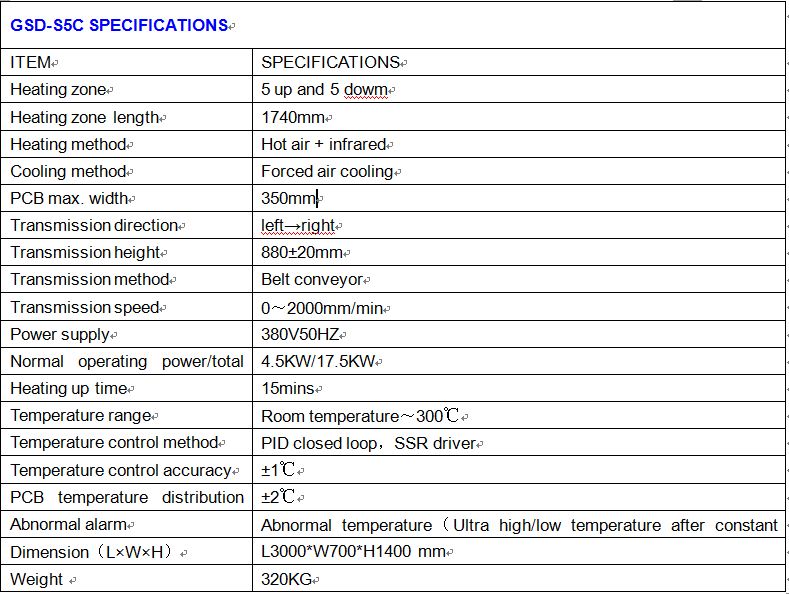

Use:

-

LED SMT PCB soldering

-

Voltage:

-

AC380V 50/60HZ

-

Dimensions:

-

3000mm(L)*700mm(W)*1400mm(H)

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

17.5 kW

-

Current:

-

50/60Mhz

-

Weight (KG):

-

320 KG

-

After-sales:

-

Field installation, commissioning and training

-

After-sales Service:

-

Video technical support

-

After-sales Services:

-

Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control System:

-

PC & PLC

-

PCB Size:

-

350 mm (Wide Max)

-

Temperature Range:

-

Room Temprature ~ 300℃

-

Temprature Accuracy:

-

±1~2 ℃

-

Certification:

-

ROHS CE ISO

Quick Details

-

Applicable Industries:

-

SMT

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GRANDSEED

-

Use:

-

LED SMT PCB soldering

-

Voltage:

-

AC380V 50/60HZ

-

Dimensions:

-

3000mm(L)*700mm(W)*1400mm(H)

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

17.5 kW

-

Current:

-

50/60Mhz

-

Weight (KG):

-

320 KG

-

After-sales:

-

Field installation, commissioning and training

-

After-sales Service:

-

Video technical support

-

After-sales Services:

-

Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control System:

-

PC & PLC

-

PCB Size:

-

350 mm (Wide Max)

-

Temperature Range:

-

Room Temprature ~ 300℃

-

Temprature Accuracy:

-

±1~2 ℃

-

Certification:

-

ROHS CE ISO

Features

1. The overall appearance of the machine has smooth lines, and the production lines are smooth and beautiful. The surface is treated with electrostatic spraying, which is neat and beautiful, not easy to peel off paint, not easy to peel off, with bright and high-end colors, and the overall effect is excellent. (Patent number: ZL 2011 3 0009454.2)

2. Windows operating system, with a Chinese and English interface, easy to operate and learn; Two control methods, computer control and emergency manual control, with safety protection function; (Self developed software: Guangshengde PCBASE reflow soldering control software V1.0)

3. Powerful software functions for online temperature measurement of PCB boards, and real-time analysis, storage, and printing of data curves;

4. Automatic monitoring, displaying the working status of the equipment, facilitating real-time monitoring of the equipment;

5. To extend the service life of the motor, our company's technical personnel specialize in design; Enable internal cooling circulation convection to lower the temperature around the motor to around 38 ℃ ;

6. High quality high-temperature high-speed motor with smooth air operation, low vibration, and low noise

7. Professional wind turbine design, stable wind speed, effectively preventing the uniformity of wind when PCB boards are heated, achieving the highest repeated heating

8. Each temperature zone adopts forced independent circulation, independent PID control, and independent heating mode up and down, making the furnace chamber temperature accurate, uniform, and with large heat capacity

9. An online UPS equipped with power outage protection function ensures that the PCB board can output normally without damage after power outage

10. An independently controlled cooling system with forced air cooling; Temperature of PCB board after discharge ≤ 50 ℃

11. The insulation layer is made of high-quality aluminum silicate insulation material, with a multi-layer insulation furnace design. The surface temperature of the outer shell of the furnace is about 5 degrees higher than the ambient temperature, effectively reducing the working environment temperature. The insulation effect is good, and the temperature rises quickly, from room temperature to working temperature ≤ 20 minutes; Special furnace design, with the lowest power consumption in the industry;

12. The skeleton is made of 40 × 80 flat pipes, and the steel frame structure is reasonable and not easy to deform. The welding adopts secondary protection welding, which is stable and solid. The outer garment is made of T: 2.0 national standard Ansteel cold-rolled plate, processed by CNC machine tool. The upper cover is designed reasonably and can be easily opened, with mechanical structure support, Check and maintain the motor, the wiring is convenient and simple. Checking and maintaining the motor is more convenient and simple. Enable safety and save effort. The overall design is reasonable, efficient, energy-saving, safe, and environmentally friendly; (Patent number: ZL 2010 2 065146.8)