Q: How can i get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: Can I buy samples placing orders?

A: Yes.Please feel free to contact us. The sample is free, you only need to pay the shipping cost. When you place an order again, we will refund the shipping cost of the sample order for you.

Q: What is your lead time?

A: It depends on the order quantity and the season you place the order. Usually we can ship within 7-15 days for small quantity, and about 30 days for large quantity.

Q: You a manufacturer or trader? Do you provide OEM/ODM services?

A: We are a manufacturer of sealants and water-based paints. We have three production bases in China, and have fully automatic production lines, which can meet different order requirements. We provide OEM and ODM services, welcome to contact us.

Q: What is your payment term?

A: T/T, Western Union, L/C and Paypal. This is negotiable.

Q: What is the shipping method?

A: It could be shipped by sea, by air or by express(EMS, UPS, DHL, TNT, FEDEX and ect).Please confirm with us before placing

o

rders.

Q

:

How to use silicone sealant

?

A:

Here are the general steps for using silicone sealant:

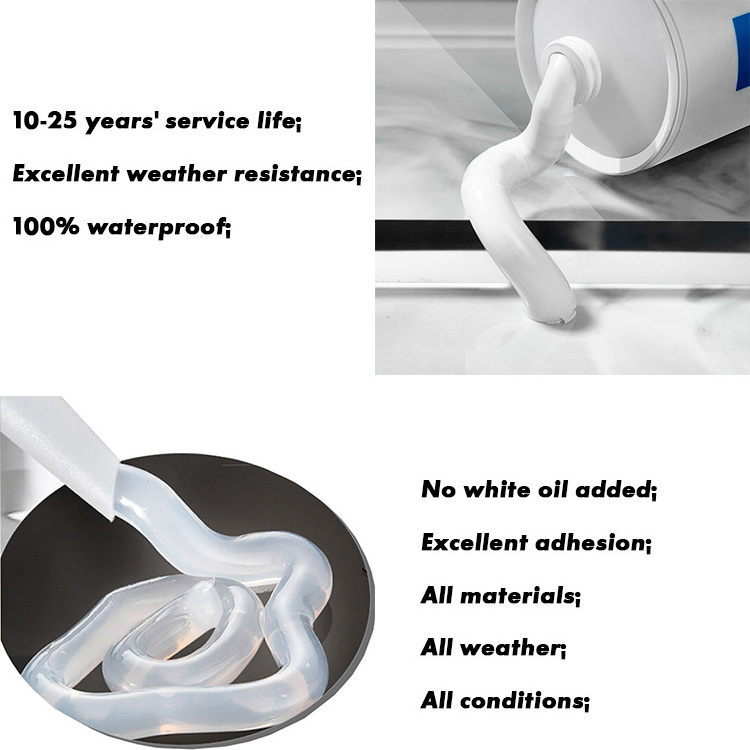

1. Prepare the surface: Before applying silicone sealant, the surface must be clean and dry. Remove any dirt, grease, or other contaminants using a cleaning solution and allow the surface to dry completely.

2. Cut the tip of the sealant tube: Cut the tip of the tube at a 45-degree angle using a sharp knife or scissors. The size of the opening will depend on the width of the joint you are filling.

3. Apply the sealant: Apply the sealant using a caulking gun, starting at one end of the joint and working your way to the other end. Apply a steady and continuous bead of sealant, making sure to fill the entire joint.

4. Smooth the sealant: Use a tool or your finger to smooth the sealant, making sure to create a consistent and even seal. You can also use a wet finger or tool to achieve a smooth finish.

5. Allow the sealant to dry: The drying time will depend on the type of silicone sealant used, as well as the temperature and humidity conditions. Read the manufacturer's instructions to determine the drying time.

6. Clean up: Clean up any excess sealant using a damp cloth or paper towel. You can also use a solvent such as rubbing alcohol to remove any sealant residue.

It is important to follow the manufacturer's instructions and safety precautions when using silicone sealant. Make sure to wear protective clothing, gloves, and eyewear if required.

Q:

What is the difference between 100% silicone and extended silicone?

A:

100% silicone and extended silicone are two different types of silicone sealants. Here are the main differences between the two:

Composition: 100% silicone sealant is made entirely of silicone polymer, while extended silicone sealant is a hybrid product that combines silicone with other materials, such as hydrocarbons or mineral oils.

Properties: 100% silicone sealant has superior adhesion and flexibility properties compared to the extended silicone sealant. It is also more resistant to temperature changes, UV radiation, and chemicals.

Durability: 100% silicone sealant is generally more durable than extended silicone sealant, and it can last for up to 20 years without losing its sealing properties. Extended silicone sealant may need to be replaced sooner, depending on the application and conditions.

Price: 100% silicone sealant is generally more expensive than extended silicone sealant, due to its higher quality and superior properties.

Application: Both types of silicone sealant are easy to apply and can be used for a variety of applications, such as sealing gaps, cracks, and joints. However, 100% silicone sealant is better suited for applications where superior adhesion and flexibility properties are required, such as in the construction and automotive industries. Extended silicone sealant is more commonly used for general-purpose applications.

Overall, the choice between 100% silicone and extended silicone sealant depends on the application and the desired properties. If superior adhesion and flexibility are required, 100% silicone sealant is the better choice. However, if cost is a concern, or if the application does not require the highest level of performance, extended silicone sealant may be a suitable alternative.