- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

45-55KW/H

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

6000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Plasma Nitriding PVD coating machine

-

Technology:

-

PVD(Physical Vapor Deposition)

-

Power supply:

-

380V,50Hz,3Phase

-

Dimension:

-

D900*H1000mm

-

Control mode:

-

PLC control system,full automatic cotrol

Quick Details

-

Machine Type:

-

pvd vacuum coating machine, Coating Equipment, vacuum coating

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HCVAC, HUICHENG

-

Voltage:

-

380V

-

Power:

-

45-55KW/H

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

6000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Plasma Nitriding PVD coating machine

-

Technology:

-

PVD(Physical Vapor Deposition)

-

Power supply:

-

380V,50Hz,3Phase

-

Dimension:

-

D900*H1000mm

-

Control mode:

-

PLC control system,full automatic cotrol

Product Description

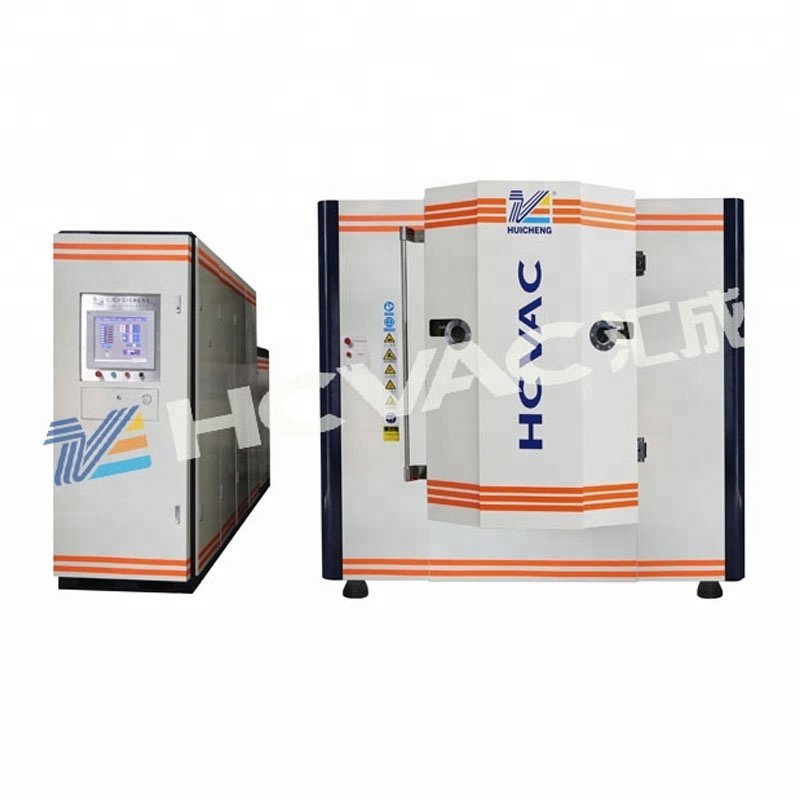

Plasma Nitriding PVD coating machine/Ion plasma sputtering vacuum PVD coating machine uses the magnetron sputtering cathode glow discharge technique to ionize and deposit the molecule(target) on the base material(PVD), as well as the resistance heating technique in the vacuum to melt the metal wire and or vaporize the metal molecule. Thus it can metallize the plastic surface of the base material, mobile phone shell, etc. Use the special filming to achieve the function of nonconductive products and electromagnetism shield, thereby to reach the standard of high-end electronic products manufacturing industry.

Benefits of PVD

Increase life span of the PVD coated products

Corrosion resistance

Chemical resistance

Wear resistance

Friction resistance

Superior Decorative finish

Uniform coating

Low maintenance cost

Environment friendly

Will not tarnish / fade

Re coating possible at a high quality level

Benefits of PVD

Increase life span of the PVD coated products

Corrosion resistance

Chemical resistance

Wear resistance

Friction resistance

Superior Decorative finish

Uniform coating

Low maintenance cost

Environment friendly

Will not tarnish / fade

Re coating possible at a high quality level

Features

The equipment integrates the plasma treatment, high-end cathode magnetron sputtering, resistance evaporation coating equipment, large load rotation frame and the automatic control technique. It has the reliable work, good repeatability and consistency., fast deposition rate, high adhesion, fine film, etc. The coating film is dense and hardness with low friction coefficient, to keep the smoothness of original workpiece surface, good flexibility, hard to break and fall.

The equipment makes full automation of the coating technology come true. It uses the vacuum coating technique to coat on the surface of the base material. It has the features of low cost, high qualification rate, green environmental protection, etc.

The equipment makes full automation of the coating technology come true. It uses the vacuum coating technique to coat on the surface of the base material. It has the features of low cost, high qualification rate, green environmental protection, etc.

Color :

Imitation gold series:

TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au, Cu

Silver white series: CrN, CrSiN, Zr (micro N)

Grey series: Ti, stainless steel (S.S), (S.S) N

Coffee color series: TiCN, TiAlCN, ZrC

Blue series: TiO, CrO, TiALN

Black Series: TiC, TiC+iC, TiCN, TiAlN, TiAlCN, Ti (C, O) and DLC

Rose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au, Cu

Silver white series: CrN, CrSiN, Zr (micro N)

Grey series: Ti, stainless steel (S.S), (S.S) N

Coffee color series: TiCN, TiAlCN, ZrC

Blue series: TiO, CrO, TiALN

Black Series: TiC, TiC+iC, TiCN, TiAlN, TiAlCN, Ti (C, O) and DLC

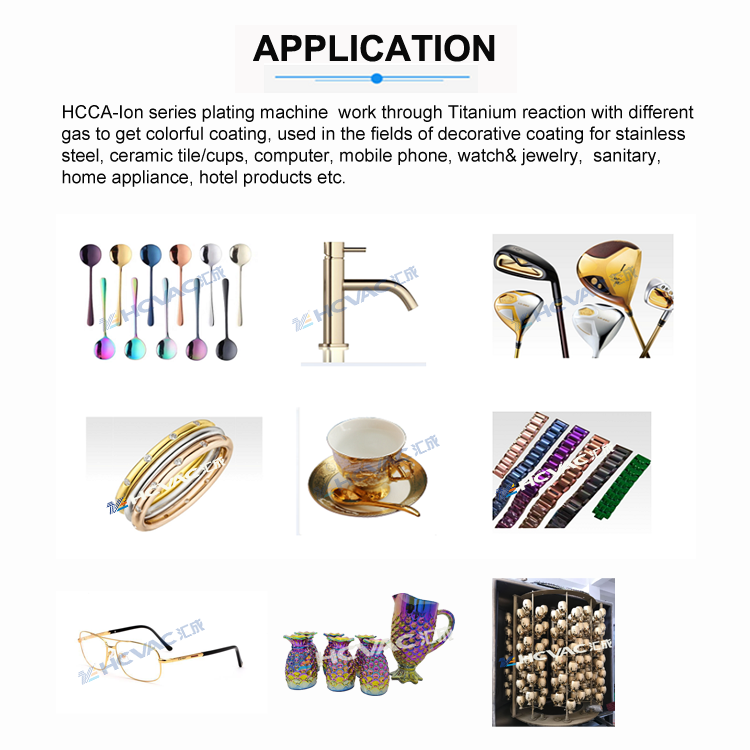

Application

Hot Searches