- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

800

-

Raw material:

-

Coconut Shell

-

Product name:

-

Hardwood Charcoal Carbonization Stove

-

Key Words:

-

Charcoal Making Equipment Carbonization Kiln

-

Feature:

-

High Carbonizing Efficiency

-

Name:

-

Wood Sawdust Continuous Carbonization Furnace

-

Function:

-

Sawdust Briquette Carbonizing Machine

-

Keywords:

-

Charcoal Cabonization Furnace

-

Usage:

-

Forestry Biomass Charring Making

-

Final product:

-

Rice Straw Charcoal

-

Other name:

-

Continuous Rotary Drum Carbonization Furnace

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

songbai

-

Effective Volume:

-

7CBM

-

Weight (KG):

-

800

-

Raw material:

-

Coconut Shell

-

Product name:

-

Hardwood Charcoal Carbonization Stove

-

Key Words:

-

Charcoal Making Equipment Carbonization Kiln

-

Feature:

-

High Carbonizing Efficiency

-

Name:

-

Wood Sawdust Continuous Carbonization Furnace

-

Function:

-

Sawdust Briquette Carbonizing Machine

-

Keywords:

-

Charcoal Cabonization Furnace

-

Usage:

-

Forestry Biomass Charring Making

-

Final product:

-

Rice Straw Charcoal

-

Other name:

-

Continuous Rotary Drum Carbonization Furnace

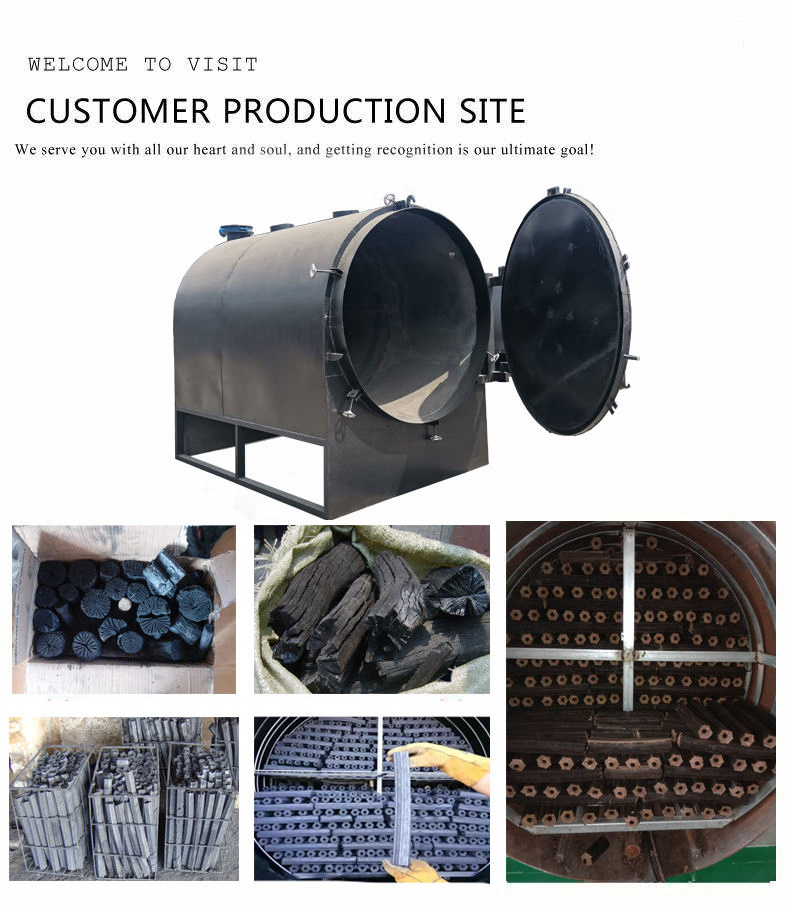

Products Description

Factory suppliers bamboo biochar making machine wood logs charcoal Carbonizing Furnace for BBQ

Charcoal carbonizing furnace is a kind of new air flow type carbonization stove, can also be called as charcoal carbonization stove. It is used to make charcoal from wood and all kinds of biomass. It adopts new advanced hot air carbonizing technology, greatly improves the carbonization rate to 99%, compared with the carbonization rate 80% of traditional carbonization stove! Its charcoal making time is short .This kind stove is safe and easy to operate,the charcoal made from the carbonizing furnace can be the material of activated carbon. thus it is very famous among many industries like charcoal making industry and boiler industry!

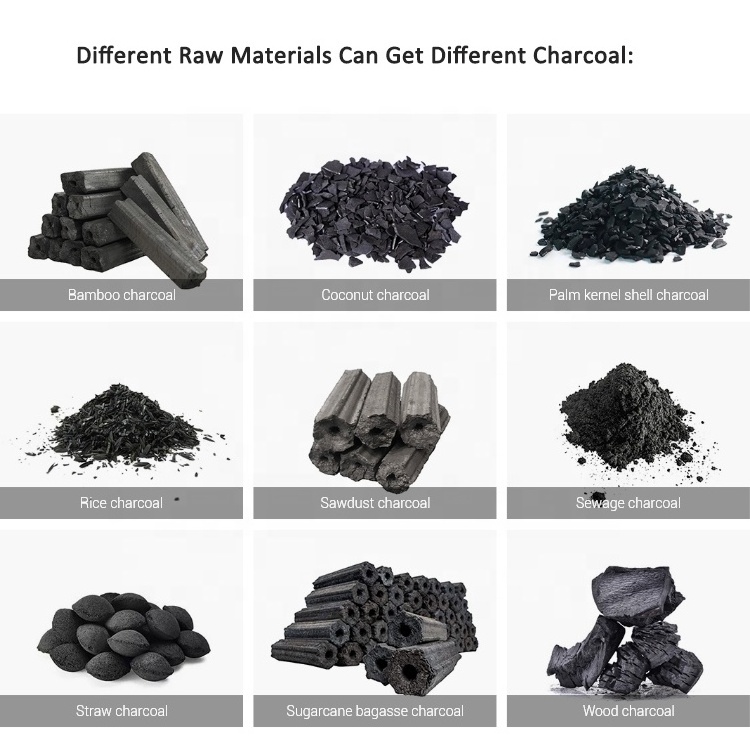

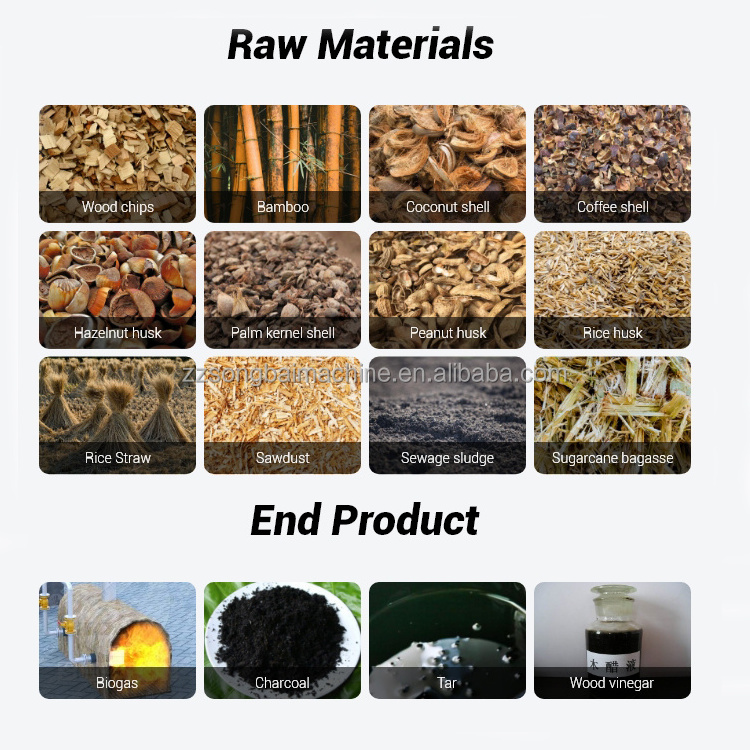

Raw material&Final products

Available Raw Materials for Production:

Almost all the biomass can be made into charcoal, we list some as follow: Wood logs, wood branches, sawdust briquettes, biomass waste, coconut shell, Macadamia nut, cashew nut shell, bamboo, etc.

Almost all the biomass can be made into charcoal, we list some as follow: Wood logs, wood branches, sawdust briquettes, biomass waste, coconut shell, Macadamia nut, cashew nut shell, bamboo, etc.

Product Paramenters

|

Model

|

Inner size

|

Dimension

Length Width Height

|

Weight

|

Carbonization cycle

|

Output

|

|

8015

|

0.8*1.5

|

1.7*1.*1.2

|

0.38ton

|

8-10h

|

150-200kg

|

|

1215

|

1.2*1.5

|

1.7*1.4*1.8

|

0.6ton

|

10-12h

|

200-300kg

|

|

1515

|

1.5*1.5

|

1.8*1.7*2.1

|

0.9ton

|

18-20h

|

400-500kg

|

|

1330

|

1.3 * 3

|

3.2*1.6*2.2

|

1.6ton

|

18-24h

|

700-800kg

|

|

1530

|

1.5*3

|

3.2*1.8*2.3

|

2ton

|

18-24h

|

800-1000Kg

|

|

1545

|

1.5*4.5

|

4.6*1.8*2.3

|

2.8 ton

|

18-24h

|

1800-2000kg

|

|

1960

|

1.9 * 6

|

6.2*2.3*2.7

|

6 ton

|

24-35h

|

2800-3000 kg

|

Product Display

Features:

1. Using horizontal manufacturing process, with a three-layer structure. Layer in the middle using light insulation materials, to save the heat during the process.

2. Block air using packing seal for the door, to get much more carbon capacity output Per Day than conventional carbonization furnace.

3. Green Energy Saving. During the process will produce a lot of light yellow combustible gas, which can make combustible gas transfer to the charring furnace combustion zone get a second fire heating. While excess gas can be used to dry the sawdust or to burn the boiler.

4. Efficient and convenient. Takes less cooling time, natural cooling using the inter layer of the gap between the unit water cooling carbonization furnace.

5. Reduce worker labor intensity. Already with a track and kiln car, .

6. Can be customized according to buyer's Materials and working process.

Hot Searches