- Product Details

- {{item.text}}

Quick Details

-

electric mucking rock loader:

-

loading width1900mm

-

mucking rock loader:

-

Discharge height 1250mm

-

electric mucking loader dumping reach:

-

350mm

-

muck loader max operation height:

-

1940mm

-

Keywords:

-

Tunnel Mucking Machine

-

Certificate:

-

TUV,BV,SGS,CE,ROHS

-

Motor power:

-

2*10.5Kw

-

weight:

-

3400kg

Quick Details

-

Place of Origin:

-

China

-

electric tunnel rock loader capactiy:

-

40cbm/h

-

electric mucking loader bucket capacity:

-

0.2cbm

-

electric mucking rock loader:

-

loading width1900mm

-

mucking rock loader:

-

Discharge height 1250mm

-

electric mucking loader dumping reach:

-

350mm

-

muck loader max operation height:

-

1940mm

-

Keywords:

-

Tunnel Mucking Machine

-

Certificate:

-

TUV,BV,SGS,CE,ROHS

-

Motor power:

-

2*10.5Kw

-

weight:

-

3400kg

Gold Mining Rock Loader, Electric Tunnel Mucking Machine

Jiangxi shicheng mine machinery factory

concentrate in mining equipments since 1985

introduction of gold mining rock loader, electric tunnel mucking machine

The tunnel electric rock loader is rail wheel type for underground tunneling and mining field light loading equipment. It is compact, adaptable, reliable, easy operation and maintenance, all the general rock, gravel, iron ore,coal ore, gold ore, granite and other metal or non-metal mines can be load.

Loaded blocks of up to 500mm, when fragmentation when 100-400mm, the highest loading efficiency, it is suitable for a variety of levels of the mine tunnel (slope <8 °).

The tunnel electric rock loader is bucket style with front loading and back unloading, self-propelled. This type of electric rock loader is suitable for nonferrous, gold mining various types of mine area or diversion tunnel project, with high durability, long life and other advantages. This machine is not explosion-proof products, don't use in the environment with methane and other flammable gases etc.

Safty requirement of gold mining rock loader, electric tunnel mucking machine

1. Strictly prohibit other people to operate the machine expect the technicist.

2. Strictly prohibit two people work at each side together.

3. Strictly prohibit check the machine before the electric motor put off.

4. Scope of application: section of the tunnel: width: >=1.8m, Height: >=2.0m.

Advantage of gold mining rock loader, electric tunnel mucking machine

1.The electric rock loader is compack in structure which stafied narrow roadway .it is stable in operation,with no need of maintenance at the front 2000 hours

2.The Z20 electric rock loader can load wide range of materials .it is of high efficiency.

3.The electric rock have great humidity resistance. it can be used in dry or damp places

4.The electric rock loader adopt alloy wear resistance materials which can be in utilization for a long time

Structure of gold mining rock loader, electric tunnel mucking machine

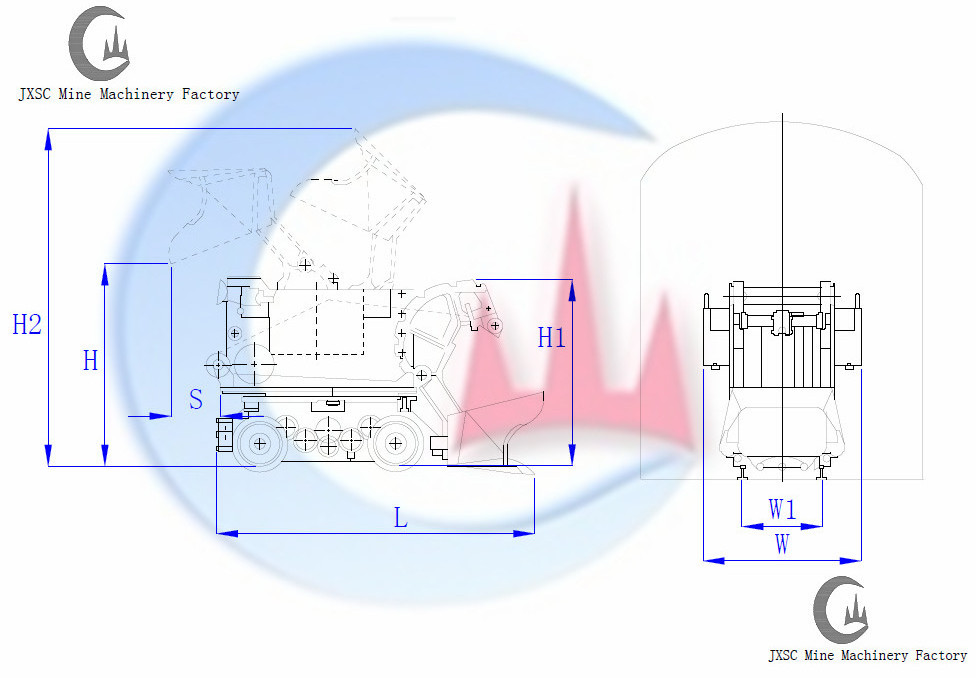

Specification of gold mining rock loader, electric tunnel mucking machine

| Model | Z20 | Z30 | |

| parameter | |||

| load capacity | 40cbm/h | 60cbm/h | |

| bucket capacity | 0.2cbm | 0.3cbm | |

| loading Width | 1900mm | 2200-2500mm | |

| Discharge height (H) | 1250mm | 1300mm | |

| Dumping reach (S) | 350mm | 350mm | |

| Max operating height (H2) | 1940mm | 2250mm | |

| Travel speed | 0.99m/s | 0.99m/s | |

| motor model | JI2-8 | JI2-8 | |

| motor power | 2x10.5kw | 2x13kw | |

| track gauge | 600mm (customized) | 600mm (customized) | |

| overall diamension | L (bucket is down) | 2120mm | 2590mm |

| W | 1070mm | 1200mm | |

| H (bucket is down) | 1305mm | 1443mm | |

| machine weight | 3400kg | 4300kg |

usersite picture of gold mining rock loader, electric tunnel mucking machine

The safety operation regulations of gold mining rock loader, electric tunnel mucking machine:

1. before the operation, the driver must check carefully the wiring connecting the machine ministries conditions and electrical equipment is good to observe the tunnel blasting, check the track gauge is correct, laying length is sufficient, make sure there is no problem operable rear.

2. during the operation, where the manipulation of the driver side, from the side wall of rock loader and roadway needs in 300mm or more, otherwise not allowed to operate, in order to avoid crushing the driver.

3. prohibit any person close to the bucket of range of motion.

4. checking, oiling and repairing rock machine, rock loader must first enable the various components are in a stable condition, is prohibited oiling or cleaning rock dust while the machine is working.

5. prohibit any work under the bucket when the bucket alone traction chain instituted.

6. without electrician, the driver don't remove or repair electrical equipment by yourself.

7. do not manipulate a rock loader by 2 person.

8. if not a loader driver, do not press the button of loader without any driver.

9. before you leave the rock loader, you must cut off the power to the electric machine should notify staff around.

10. before blasting, rock loader must retreat to a safe distance.

11. such as the need to open the lid to manipulate child maintenance, must first turn off the power, and then use the electroscope inspection before overhaul confirm power outages.

12 contactor is burning more serious, should be replaced on time.

13 rock loader when moving, the driver must pay attention to the location of the cable to avoid being crushed by rail wheels.

14 during operation, such as the failure should be immediately stopped, identify the cause and repair, before the discovery of the fault do not eliminated shall continue to use it.

15. tunnel must match the standard requirements, straight and not open to help pull the end of the phenomenon. If you do not match the specifications, should be reworked.

JXSC other main products

if you are interested in our machines or need any further information

welcome to contact us and visit our factory