- Product Details

- {{item.text}}

Quick Details

-

Cooling Mode:

-

WATER COOLING

-

Control Software:

-

EZCAD

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

SUNDOR

-

Marking Head Brand:

-

SINO

-

Weight (KG):

-

50 KG

-

Configuration:

-

split type

-

Laser Power:

-

3W/5W/10W

-

Voltage:

-

110v / 220V / 50-60Hz

-

Laser wavelength:

-

355nm

-

Products:

-

CE certificate laser marking machine for acrylic glass metal plastic

-

Cooling system:

-

Watercooling

-

Marking material:

-

almost all the materials, glass, paper, plastic, metal etc

-

Minimum Line Width:

-

0.015mm /UV Laser Marking

-

Minimum Character:

-

0.15mm*0.15mm

-

Laser source:

-

UV laser

-

Marking range:

-

110*110mm optional other range

Quick Details

-

Working Accuracy:

-

0.001 mm

-

Graphic Format Supported:

-

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

-

Laser Type:

-

UV

-

Cooling Mode:

-

WATER COOLING

-

Control Software:

-

EZCAD

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

SUNDOR

-

Marking Head Brand:

-

SINO

-

Weight (KG):

-

50 KG

-

Configuration:

-

split type

-

Laser Power:

-

3W/5W/10W

-

Voltage:

-

110v / 220V / 50-60Hz

-

Laser wavelength:

-

355nm

-

Products:

-

CE certificate laser marking machine for acrylic glass metal plastic

-

Cooling system:

-

Watercooling

-

Marking material:

-

almost all the materials, glass, paper, plastic, metal etc

-

Minimum Line Width:

-

0.015mm /UV Laser Marking

-

Minimum Character:

-

0.15mm*0.15mm

-

Laser source:

-

UV laser

-

Marking range:

-

110*110mm optional other range

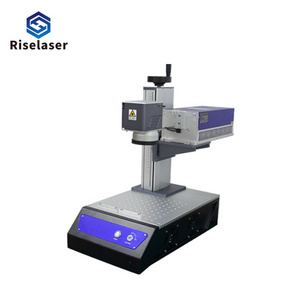

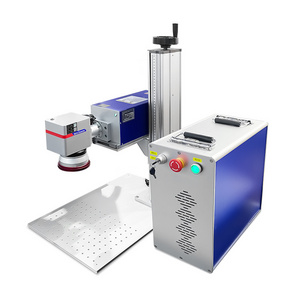

CE ROHS FCC certificate 3w laser marking machine for acrylic glass metal plastic

Welcome to our UV Laser Marking Machine.

Are you searching for a cutting-edge solution to elevate your marking processes to the next level? Sundor UV Laser Marking Machine is the answer to your marking needs, offering precision and versatility to meet the demands of diverse industries.

From metals and plastics to glass and ceramics, our UV laser marking machine excels in marking a wide array of materials. It's the ultimate all-in-one solution for diverse applications across various industries.

At Sundor laser, we believe in bring exceptional value to our customers. That's why we provide:

| 1 hour quick response | Save your time and solve your worried |

| 2 year warranty | Perfect after-sales system to solve all your problems |

| C ustomized solutions | Business start from listening, OEM, ODM your application |

| W orld-brands Parts | Guarantee the equipment running stable & long working life |

| C E, ROHS, ISO certification | Quality certificated by European company |

| E asy to learn & operation | Improve working effective |

Following are some parameters of UV laser marking machines:

| Parameters |

Details |

|

Laser type |

UV laser |

|

Laser wavelength |

355 nm |

|

Function |

Precision marking on all materials |

|

Laser Power |

3W / 5W / 10W (optional) |

|

Working Acccuracy |

0.001mm |

| file format support |

Vector file (AI, PLT, DXF etc) & Bitmap files( BMP, etc) |

|

Cooling mode |

Water cooling |

|

Operating Voltage |

110V / 220V / 380V |

|

Total power |

500W |

|

Marking area |

110*110mm (others could be optional) |

Now, let's show you how to choose suitable UV laser marking machine:

1. The materials you want to be marking:

We need to know what's materials you want to marking, (text, graphics, barcodes, etc.), and c onsider the marking size and content complexity, as well as any special requirement.

Sundor laser could free testing the marking effects for your reference.

2. Confirm Marking Speed and Volume Requirements:

If your production have large volume, we need to evaluate the expected production volume and the required marking speed. High-volume production may necessitate a faster machine with automated features to enhance productivity.

3. Consider Marking Area and Size Limitations:

Check the marking area and ensure it suitable for the workpiece you intend to mark. It's essential to select a machine that can handle your largest and smallest marking requirements.

4. Precision and Resolution:

Evaluate the precision and resolution capabilities of the machine. This is very important for industries that require fine details and high-quality markings, such as electronics or jewelry.

5. Ease of Use and Software:

Whether the software user interface is friendly easy to operate. Ask how easy it is to set up and configure the machine.

6. Maintenance and Reliability:

Look for a UV laser marking machine that offers low maintenance and has a reputation for consistent performance. Meantime, famous brand parts also determine the quality of laser equipment.

Sundor laser UV laser marking machine all adopt Chinese famous brand parts, which will bring you different feeling of equpment.

7. Training and Support:

Inquire about the training and support provided by the manufacturer. Adequate training for your operators will ensure proper utilization of the machine, and reliable support is essential for troubleshooting and maintenance.

8. Budget and ROI:

Consider your budget and the return on investment (ROI) the UV laser marking machine can provide. While cost is a factor, prioritize value and long-term benefits over the initial investment.

UV laser marking machines are suitable for almost all kinds of materials and various industries. Especially for the condition which fiber laser marking machine and CO2 laser marking machine no method to match effects of requirement.

Follows are some photos which marked by UV laser marking:

If you have any precision marking demand on different kinds of materials, please contact us at any time. We will free testing for your reference.

Waiting for your kindly message.

The UV laser marking machine packing by wooden cases

Presales and after-sales services are crucial aspects when considering the purchase of a laser marking machine.

Pre-Sales Service:

1. Consultation: As a reputable laser marking machine provider, Sundor laser will offer consultation services to understand your specific needs and requirements. Sundor laser will assess your applications, materials, production volumes, and budget to help you choose the most suitable machine for your needs.

2. Machine Demonstration: Sundor laser often offer machine demonstrations to showcase the capabilities and features of their laser marking machines. You could see the machine in action and evaluate its performance and precision.

3. Application Support: Sundor laser can assist you in determining the best settings, techniques, and processes for your specific applications. We could offer guidance on optimizing your designs for laser marking and provide sample welding to help you understand the machine's capabilities.

4. Customization: If customers have unique requirements, suppliers may offer customization options to tailor the laser marking machine to their specific needs.

5. Training: Pre-sales services may include training sessions on how to operate the laser marking machine. These sessions can be customized to your needs and may cover topics such as machine setup, software operation, etc.

6. Technical Support: Pre-sales service often includes technical support, where customers can discuss their requirements with experts who can provide guidance and suggest appropriate solutions.

7. Site Evaluation: Depending on the size and complexity of the laser cutting machine, Sundor laser may offer a site evaluation to ensure that your workspace meets the requirements for installation and operation.

After-sales Service:

1. Installation: Sundor laser will provide train videos & online meeting to support clients install and adjust laser marking machine.

2. Training and Support: After installation, Sundor laser should offer comprehensive training to your operators, covering all aspects of machine operation, maintenance, troubleshooting, and safety protocols. Sundor laser could also provide ongoing technical support to address any questions or issues that may arise during the machine's working life.

3. Warranty: The UV laser marking machine warranty 1 years. After warranty, Sundor laser will also provide technology support for the equipment. Solve all of your worried.

4. Maintenance and Servicing: Laser marking machines require regular maintenance to ensure optimal performance. Sundor laser will offer maintenance plans, providing periodic servicing, inspections, and repairs as needed.

5. Spare Parts and Consumables: Sundor laser stock and provide spare parts and consumables for the laser marking machines we sell. Ensures customers can easily obtain replacement parts or consumables when needed.

6. Customer Support: Sundor laser have a responsive customer support team available to assist you with any inquiries, technical issues, or general assistance. This support can be provided through various channels such as phone, email, or an online support portal.

It's important to carefully consider the presales and after-sales services offered by different providers when purchasing a laser marking machine. These services can greatly impact your overall experience, machine performance, and long-term satisfaction with your investment. Welcome to choose Sundor Laser, waiting for your kindly message. Thank you.

Following is some of remarks from our Clients:

Why SUNDOR Laser

FAQ for Laser Marking Machine:

Q1: What is UV laser marking?

UV laser marking is a non-contact process that utilizes high-energy ultraviolet laser beams to create permanent markings on various materials. The focused UV laser beam interacts with the material's surface, causing localized photochemical reactions that result in precise and durable markings.

Q2: What materials can be marked using UV laser technology?

UV laser marking is compatible with a wide range of materials, including metals (steel, aluminum, etc), plastics (ABS, PVC, polycarbonate), glass, ceramics, rubber, and more. It is particularly well-suited for sensitive materials and delicate components.

Q3: What industries benefit from UV laser marking?

UV laser marking finds applications in various industries, including electronics, automotive, aerospace, medical devices, jewelry, promotional products, and packaging. Its versatility makes it suitable for industries requiring permanent and high-quality markings.

Q4: Can UV laser marking be automated and integrated into existing production lines?

Absolutely! UV laser marking machines can be easily integrated into existing production lines and automated systems. This allows for seamless workflow integration, increased productivity, and efficient marking processes.

Q5: How do I choose the right UV laser marking machine for my needs?

Choosing the right UV laser marking machine involves considering factors such as material compatibility, marking speed, precision, ease of use, safety features, reliability, and budget. Our expert team can assist you in selecting the most suitable machine based on your specific requirements.

Q6: What kind of support and training do you provide for UV laser marking machines?

A: At Sundor laser, we provide comprehensive technical support, on-site training for your operators, warranty coverage, and access to spare parts. Our goal is to ensure that you have a smooth and successful experience with our UV laser marking machines.

Q7: Can I see a demonstration of your UV laser marking machine?

A: Absolutely! We offer live demonstrations of our UV laser marking machines to showcase their capabilities and how they can meet your marking needs. Contact us to schedule a demonstration at your convenience.

We hope these FAQs have provided valuable insights into UV laser marking. If you have any more questions or require further information, don't hesitate to reach out to us. We look forward to serving your marking needs with our cutting-edge UV laser marking solutions!