- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/CUSTOMIZED

-

Power:

-

22kw

-

Dimension(L*W*H):

-

2300*800*3600mm

-

Weight (KG):

-

800

-

Name:

-

Homemade Straw And Sawdust Grinder /Wood Pellet Mill /Hammer Mill

-

Type:

-

BD-CP500

-

Usage:

-

Raw Material Grinding

-

Raw material:

-

Cereal Wheat Maize Grain Corn

-

Advantage:

-

High Capacity High Efficient

-

Driven Way:

-

Electric Motor Diesel Engine

-

Color:

-

Clients' Requirement

-

Feature:

-

Fully Automatic High Efficiency

-

Final product:

-

3-8cm

-

Related machine:

-

Mixer, Feed pellet machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BEDO

-

Marketing Type:

-

Hot Product 2024

-

Voltage:

-

220V/380V/CUSTOMIZED

-

Power:

-

22kw

-

Dimension(L*W*H):

-

2300*800*3600mm

-

Weight (KG):

-

800

-

Name:

-

Homemade Straw And Sawdust Grinder /Wood Pellet Mill /Hammer Mill

-

Type:

-

BD-CP500

-

Usage:

-

Raw Material Grinding

-

Raw material:

-

Cereal Wheat Maize Grain Corn

-

Advantage:

-

High Capacity High Efficient

-

Driven Way:

-

Electric Motor Diesel Engine

-

Color:

-

Clients' Requirement

-

Feature:

-

Fully Automatic High Efficiency

-

Final product:

-

3-8cm

-

Related machine:

-

Mixer, Feed pellet machine

Homemade Straw And Sawdust Grinder /Wood Pellet Mill /Hammer Mill

Product Description

Hammer crusher is a tangent-feeding hammer crusher, which can crush all kinds of dry feed, such as corn, sorghum, husk, rice straw, wheat straw, yam vine, corn stalk, peanut vine, bean stalk, etc. This series of crusher has simple structure, high production efficiency, simple operation, reliable use and easy maintenance; Suitable for farms, livestock farms, counties, township processing plants. In addition, the machine can also crush traditional Chinese medicine materials, animal bones, wood, waste paper, cow dung, pharmaceutical raw materials, chemical raw materials.

Specification

Compared with other similar products, the performance of wood crushing machine has been greatly improved.

1.The whole equipment is only driven by a motor, simple structure, compact layout, cheap price, stable work, less energy consumption, high output, wood chip machine finished product quality, low processing cost. In addition to wood, it can also be used for bamboo, thatch, corn stalk, sorghum stalk and other fibrous straw like chips.

2.Wood pulverizer can also be called wood pulverizer, large wood pulverizer, small wood pulverizer, wood sawdust machine, wood pulverizer can be processed, pine, miscellaneous wood, young wood, fir, bamboo, because the machine compact structure, small footprint, cutting quality, low power consumption, and suitable for flow operations, It is widely used in the preparation section of medium and small particleboard and fiberboard production enterprises, and can also be used in the production of commercial wood chips for individual households.

3.Wood crusher is a hammer crusher, it is mainly the use of blade chips and airflow impact principle to crush the material to be crushed. This equipment is mainly composed of crushing, grading, wind conveying, unloading and dust removal five major parts,cancel the traditional screening process, the use of wind once into powder.

1.The whole equipment is only driven by a motor, simple structure, compact layout, cheap price, stable work, less energy consumption, high output, wood chip machine finished product quality, low processing cost. In addition to wood, it can also be used for bamboo, thatch, corn stalk, sorghum stalk and other fibrous straw like chips.

2.Wood pulverizer can also be called wood pulverizer, large wood pulverizer, small wood pulverizer, wood sawdust machine, wood pulverizer can be processed, pine, miscellaneous wood, young wood, fir, bamboo, because the machine compact structure, small footprint, cutting quality, low power consumption, and suitable for flow operations, It is widely used in the preparation section of medium and small particleboard and fiberboard production enterprises, and can also be used in the production of commercial wood chips for individual households.

3.Wood crusher is a hammer crusher, it is mainly the use of blade chips and airflow impact principle to crush the material to be crushed. This equipment is mainly composed of crushing, grading, wind conveying, unloading and dust removal five major parts,cancel the traditional screening process, the use of wind once into powder.

Technical Data

After crushing the size can be adjusted according to customer requirements, is currently a best-selling domestic farm necessary equipment. A machine that uses high-speed spinning hammers to crush feed. When the material is evenly into the crushing chamber, under the action of rotating sheet continuous high-speed strike and crushing chamber rub collision, quickly broken into fine powder, through the screen through the discharge port discharged from the machine. It has the characteristics of simple structure, strong commonality, high productivity and safe use.

|

Model

|

Power

(kw)

|

Capacity

(kg/h)

|

The number of hammer pieces(pcs)

|

The size of hammer pieces(mm)

|

Packing Size

(mm)

|

Weight

(kg)

|

|

BD-CP500

|

22

|

700-1000

|

30

|

180*60*8

|

2100*1260*980

|

540

|

|

BD-CP600

|

30

|

1200-1500

|

40

|

180*60*8

|

2000*1400*1200

|

650

|

|

BD-CP800

|

45

|

2000-2500

|

60

|

180*60*8

|

2200*1500*1250

|

820

|

|

BD-CP1000

|

75

|

3000-3500

|

70

|

180*60*8

|

2200*1650*1300

|

1300

|

|

BD-CP1300

|

45+45

|

4000-5000

|

90

|

230*60*8

|

2300*1700*1400

|

2400

|

|

BD-CP1500

|

55+55

|

5000-6000

|

100

|

230*60*8

|

2300*1750*1420

|

2800

|

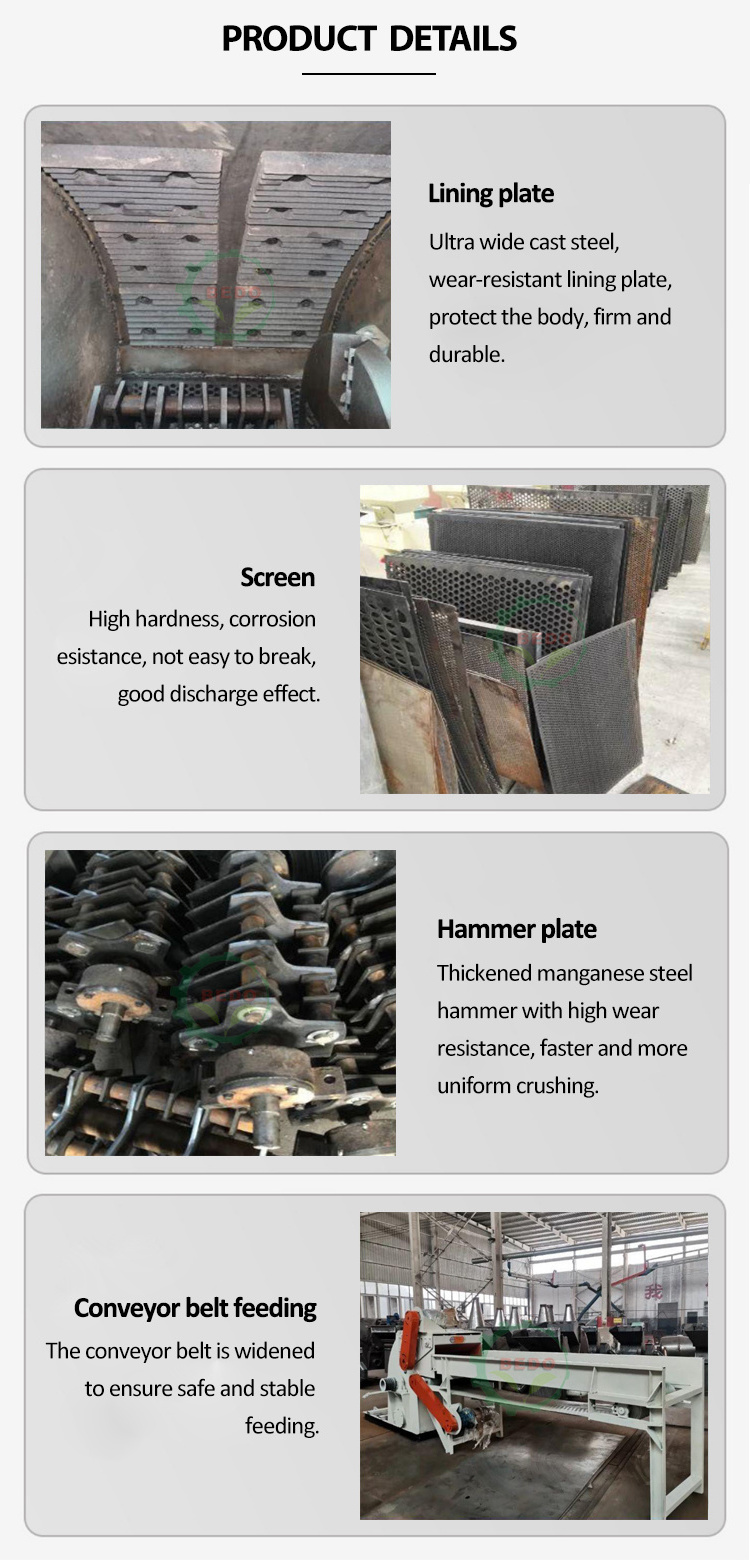

Details Images

Hammer crusher is composed of feeding hopper,upper and lower body, rotor, screen, feeding tube and other parts. Users can be equipped with storage bags or silos according to their own needs. After the material enters the crushing chamber from the hopper, it is broken by the high-speed rotating hammer.

Under the air flow, the broken material along the outer edge of the rotor, continuous and hammer, tooth plate, screen, collision,rub and be quickly crushed. The pulverized powder particles are quickly transported to the storage bag or bin through the sieve by centrifugal pressure of the rotor and suction force of the fan.

Under the air flow, the broken material along the outer edge of the rotor, continuous and hammer, tooth plate, screen, collision,rub and be quickly crushed. The pulverized powder particles are quickly transported to the storage bag or bin through the sieve by centrifugal pressure of the rotor and suction force of the fan.

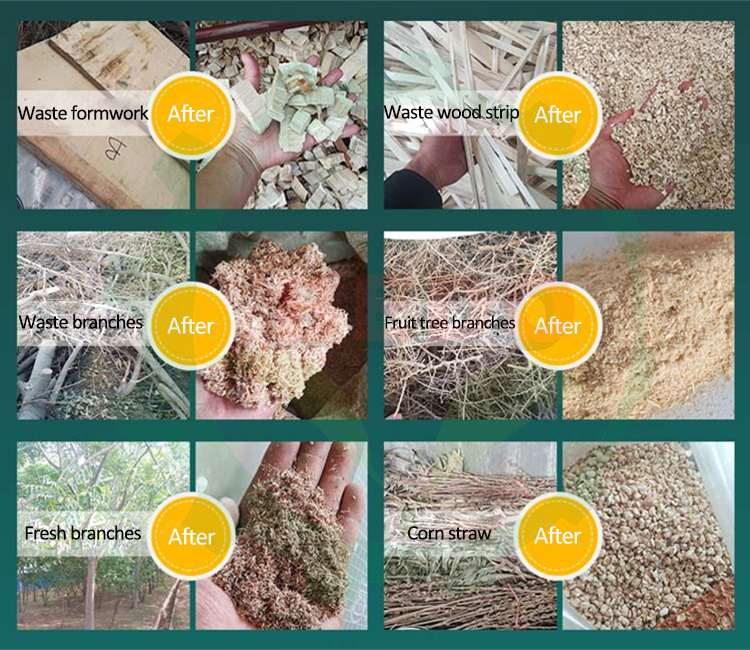

Raw Materials and Final Production

Usage and scope of application:

1.Straw dry feed:can crush chaff, belly valley, potato rattan, peanut rattan, straw, corn xuan, bean straw, etc.

2.Grain flour:rice, sweet potato, beans, wheat, jade, potatoes, etc., can be the supporting machinery of flour mill.

3.Oil processing:powder tea seeds, rapeseed, peanut, tong kernel, cotton seeds are the supporting machinery of oil press.

1.Straw dry feed:can crush chaff, belly valley, potato rattan, peanut rattan, straw, corn xuan, bean straw, etc.

2.Grain flour:rice, sweet potato, beans, wheat, jade, potatoes, etc., can be the supporting machinery of flour mill.

3.Oil processing:powder tea seeds, rapeseed, peanut, tong kernel, cotton seeds are the supporting machinery of oil press.

Packing & Delivery

Packaging

For one set charring kiln, it is packed by waterproof cloth, then packed in the container.

For more than two sets charring kiln, it is nude packing, packed in the full container.

Payment term

1. Payment: T/T, Western Union; 50% TT payment in advance, 50% TT pay the balance before delivery.

2. Warranty: 12 months for the main machine, 4-6 months for the parts.

3. Delivery time: Within 7-10 days for single machine after getting the down payment; 25-35 days for the whole production line after getting the down payment.

For one set charring kiln, it is packed by waterproof cloth, then packed in the container.

For more than two sets charring kiln, it is nude packing, packed in the full container.

Payment term

1. Payment: T/T, Western Union; 50% TT payment in advance, 50% TT pay the balance before delivery.

2. Warranty: 12 months for the main machine, 4-6 months for the parts.

3. Delivery time: Within 7-10 days for single machine after getting the down payment; 25-35 days for the whole production line after getting the down payment.

Hot Searches