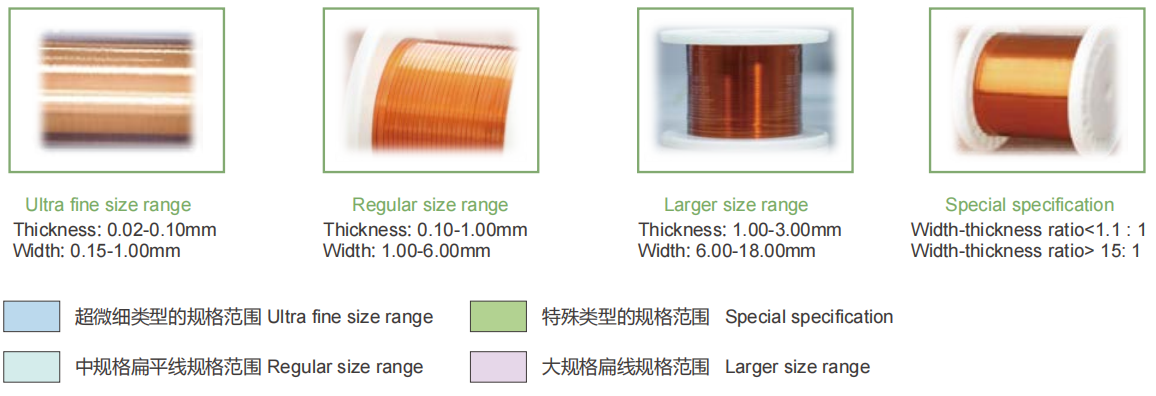

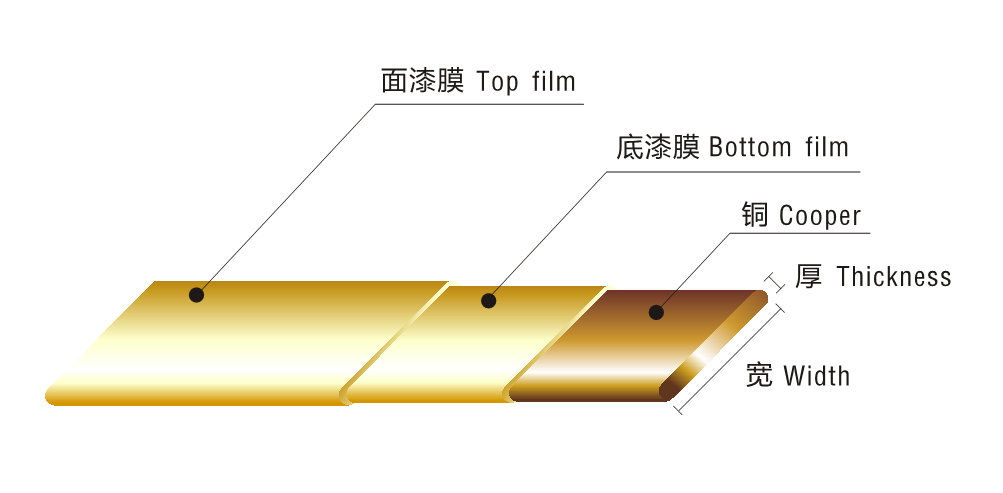

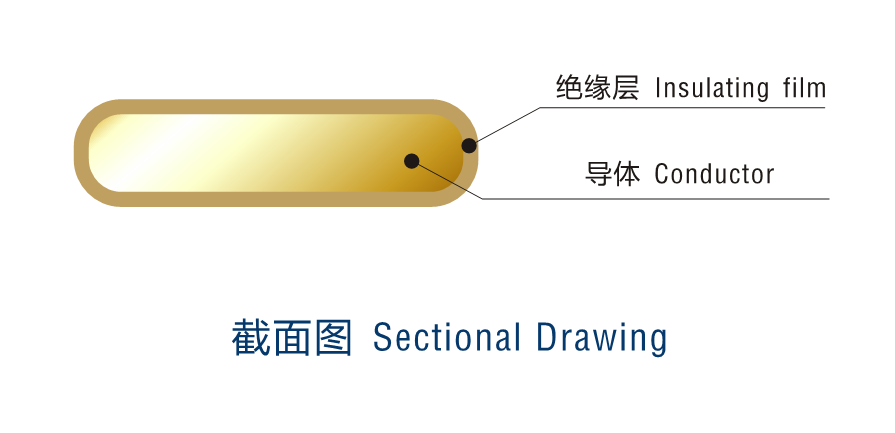

We supply rectangular enameled copper wire, it' widely used in EV, motor, etc. The rectangular enameled copper wire can be customized

according to your needs.Thickness range from 0.04mm-1.8mm. width from 0.115mm-7.5mm, class 180 to class 240 with or without self

bonding layer are available.

Applications

: EV, i

nductor, transformer, line filter,mutual inductor, motor, voice coil, solenoid valve