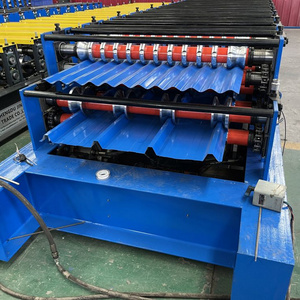

The shear head of the roof sheet roll forming machine adopts the guide column type shear, and there are reinforcement bars at the top, bottom and left and right, so the shear is more stable. The double cylinder mode makes the shear balance. The cutting head adopts blanking type cutting, and the color steel plate can be directly dropped on the workbench, saving labor. Three shapes, 828 glazed tile, 850 corrugated tile, 900 trapezoidal tile

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wadley

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

4900*1430*1900mm

-

Weight:

-

3940 kg

-

Product name:

-

Roof Sheet Forming Machine

-

Application:

-

Building Construction

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Cutting blade material:

-

Cr12 Mould Steel

-

Main frame:

-

350H Steel

-

Control system:

-

PLC(imported Brand)

-

Roller Stations:

-

8-15 Stations

Quick Details

-

Type:

-

roof sheet roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wadley

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

4900*1430*1900mm

-

Weight:

-

3940 kg

-

Product name:

-

Roof Sheet Forming Machine

-

Application:

-

Building Construction

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Cutting blade material:

-

Cr12 Mould Steel

-

Main frame:

-

350H Steel

-

Control system:

-

PLC(imported Brand)

-

Roller Stations:

-

8-15 Stations

Production Description

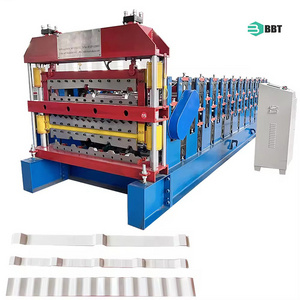

Triple Layer Roof Sheet Roll Forming Machine

Roof Sheet Double Layer Forming Machine

,it is our company most popular products in building materials machine. For roof sheet, it include many type according to its different shape, popular type include corrugated tile roll forming machine, trapezoidal tile roll forming machine,glazed tile roll forming machine, ridge cap roll forming machine and other type profile panel roll forming machine.

When you choose roof sheet three layers roll forming machine, you had better learn popular shape in local,also raw material is an important considering data, if do not have good supplier in local, we can assist you purchase it in China together. we are professional factory and in this area for many years, any requires please contact us at any time!

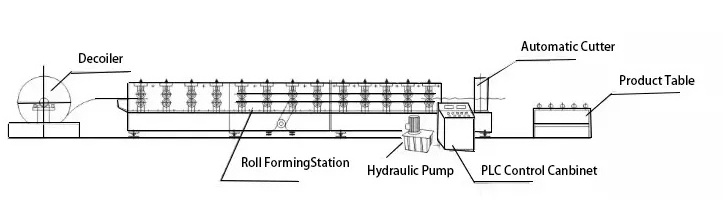

working principle.

The tile pressing machine belongs to the cold bending roll forming machine, which mainly presses the color steel plate into the required shape, size and shape by rolling. When the machine works, the power group drives the roller shaft, and the roller forming wheel is used to roll the color steel plate with the specified thickness. It is widely used in industrial and civil buildings, such as factory buildings, warehouses, gymnasiums, exhibition halls, cinemas and other rooms and walls.

The tile pressing machine belongs to the cold bending roll forming machine, which mainly presses the color steel plate into the required shape, size and shape by rolling. When the machine works, the power group drives the roller shaft, and the roller forming wheel is used to roll the color steel plate with the specified thickness. It is widely used in industrial and civil buildings, such as factory buildings, warehouses, gymnasiums, exhibition halls, cinemas and other rooms and walls.

Product Specification

|

No

|

Item

|

Data

|

|

1

|

Raw material width

|

1000-1200 mm

|

|

2

|

Sheet effective width

|

750-1000 mm

|

|

3

|

Raw material

|

Color steel sheet or galvanized steel sheet

|

|

4

|

Material thickness

|

0.3-0.8 mm or customized

|

|

5

|

Forming roller material

|

45# steel plated with chrome

|

|

6

|

Shaft diameter

|

70 mm

|

|

7

|

Forming roll station

|

8-16 steps

|

|

8

|

Main motor power

|

3 KW 4 KW 5.5 KW(according to type)

|

|

9

|

Hydraulic power

|

4 KW (according to type)

|

|

10

|

Control system

|

PLC control

|

Details Images

Shear Head.

Machine frame.

The three-layer roof sheet roll forming machine adopts welded steel frame structure to ensure more stable operation of the roof plate machine. The steel frame surface is painted and can be customized. The steel frame is equipped with roller shaft, roller wheel, chain, drive motor, hydraulic pump station and control electric box to form the whole body. AC variable frequency motor reducer drive, chain drive, roller surface polishing, hard plating, heat treatment and chrome plating.

Forming roller.

The quality of the forming rollers of the three-layer roof sheet roller press will determine the shape of the roof panel. We can customize different types of rollers. The work of the roller forming machine is to drive the roller shaft through the power group, and use the roller forming wheel to roll the color steel plate with the specified thickness. The gap of the forming wheel can be adjusted to ensure the forming effect, and the thin plate or thick plate can be selected.

Control System.

There are different types of control components of the three-layer roof plate rolling forming machine. The standard type has button control, and different functions are realized through the button. PLC touch screen type can set data on the screen. Its price is

slightly higher, but it is more intelligent and automatic. The picture is a Spanish touch screen. We set two languages, one is English, and the other can be customized according to your needs. It is easy to identify and operate.

slightly higher, but it is more intelligent and automatic. The picture is a Spanish touch screen. We set two languages, one is English, and the other can be customized according to your needs. It is easy to identify and operate.

Free accessories

.

In order to thank new and old customers for their support, we will give some of the above accessories along with the machine for free, so that everyone can use the machine.

Display and Application

Roof sheet double layer roll forming machine

is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste.

We are a professional roof panel manufacturer. We support customizing roof and wall panels in a variety of shapes. You only need to provide relevant drawings. We will customize them according to your needs, or we can provide existing shapes for you to choose. There is always a way to meet your needs.

Hot Searches