- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Grey Iron

-

Application:

-

Machinery Parts

-

Surface treatment:

-

Sand Blasting

-

Certification:

-

ISO9001

-

Tolerance:

-

Customer's Drawing Request

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

WELLEY

-

Model Number:

-

CFL76

-

Material:

-

Grey Iron

-

Application:

-

Machinery Parts

-

Surface treatment:

-

Sand Blasting

-

Certification:

-

ISO9001

-

Tolerance:

-

Customer's Drawing Request

China Manufacturer Sand Casting Cast Iron Alloy Steel Machinery Parts Sprocket Wheel Flywheel

| Description | CUSTOM MADE PRECISION CASTINGS |

| Material |

(1)grey iron, ductile iron , pig iron

(2)carbon steel, stainless steel, alloy steel (3)aluminum alloy, aluminum, A380, aluminum 6061 (4)zinc alloy ,copper, brass, bronze etc |

| Standard | ISO ,DIN, AISI, ASTM, BS, JIS, etc. |

| Size | Available in all sizes or as customer's drawings |

| Certification | ISO9001:2008 |

| Application |

Industrial parts,

Machinery parts,

construction parts,

valve parts,

train,

craft,

hydraulic pressure,

Agricultural machinery, Marine hardware, Auto parts, electric power fittings, food machinery, harness fittings, tools, mining machinery parts |

| Weight Range | 0.01kg-20000kg |

| Machining precision | ±0.01mm or customer's request |

| Surface Treatment | Heat Treatment, Polishing, Plating, Machining, Anodizing, shot, sand blasting, zinc plated, oxide, galvanized etc. |

| Process | Lost wax casting process, die casting process, sand casting process. Soluble glass casting process, silicasol casting process |

| Production Application | Metal parts, Mechanical parts, Marine Hardware, Electric power fitting, Construction parts, Pipe Fitting, Hardware, Auto parts, Valve parts, Industrial parts, Agricultural machinery, Hinges, etc |

| CNC and MC machining | Three coordinate measurement machine for testing. |

| Service | To chart to sample production; OEM / ODM |

| Packing details | Wood or carton packages as per your demands |

| MOQ | 200pcs |

Why Choose Us

Why Choose Us

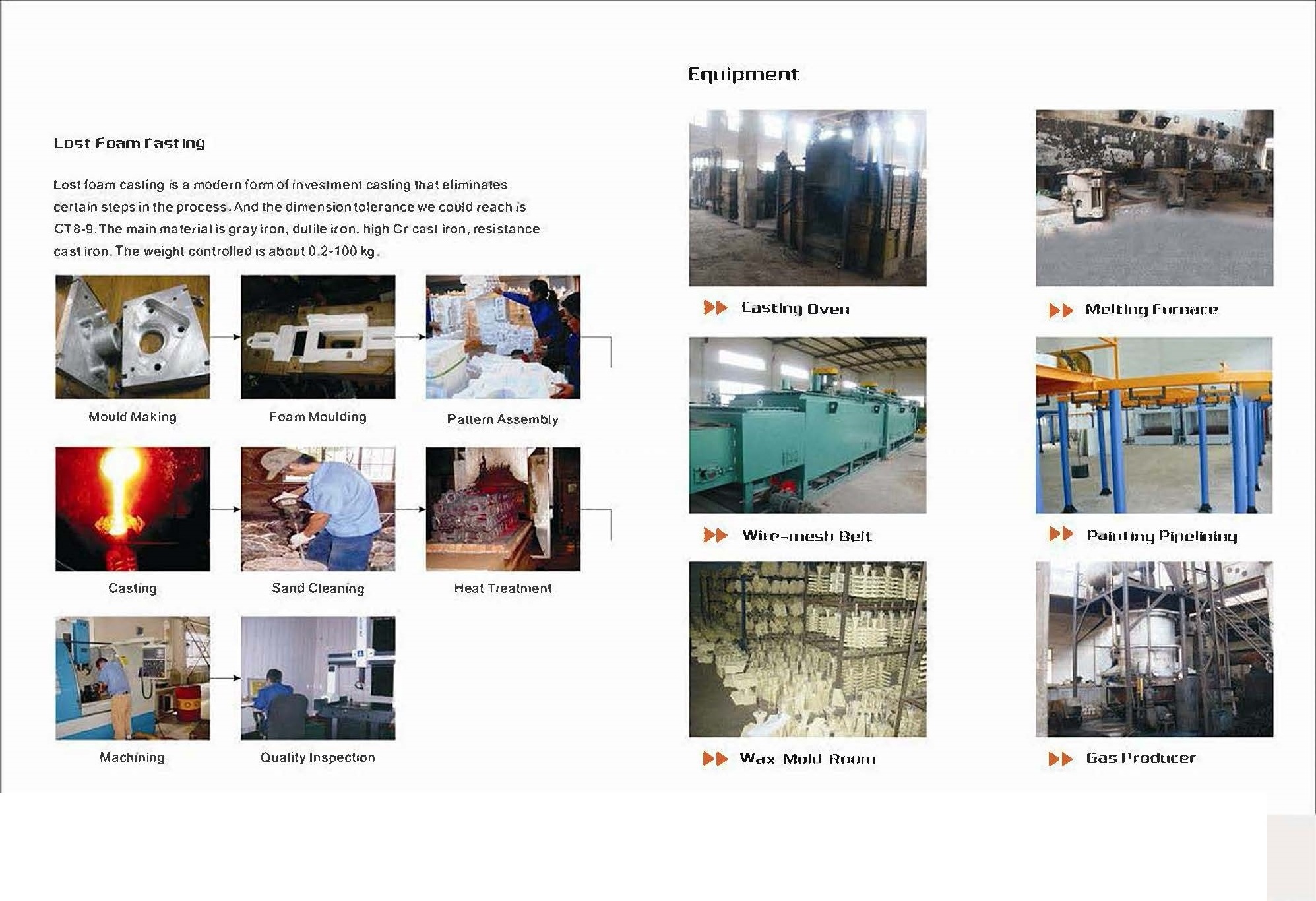

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, Transportation equipment, Power generation assembly etc.

With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house we are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market.

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

How do We Work with Our Clients?

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.;

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

1. High skilled and well-trained working team under good management environment.

2. Quick response and support for any inquiries.

3. Over 10 years professional manufacture experience to ensure high quality of your products.

4. Large and strong production capacity to meet your demand.

5. High Quality standard and hygienic environment.

6. We have very strict quality control process:

In coming Quality control (IQC) - All incoming raw material are checked before used.

In process quality control (IPQC) - Perform inspections during the manufacturing process.

Final quality control (FQC) - All finished goods are inspected according to our quality standard for each products.

Outgoing Quality Control (OQC) - Our QC team will 100% full inspection before it goes out for shipment.

Proper Quarantine procedure - For those products got rejected to pass the quality control, they will specially marked and dispose.

7. Good after sales services

8. Passed IATF16949:2016 and provide SGS/RoHS certification if needed.

With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house we are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market.

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

How do We Work with Our Clients?

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.;

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

Why choose us?

1. High skilled and well-trained working team under good management environment.

2. Quick response and support for any inquiries.

3. Over 10 years professional manufacture experience to ensure high quality of your products.

4. Large and strong production capacity to meet your demand.

5. High Quality standard and hygienic environment.

6. We have very strict quality control process:

In coming Quality control (IQC) - All incoming raw material are checked before used.

In process quality control (IPQC) - Perform inspections during the manufacturing process.

Final quality control (FQC) - All finished goods are inspected according to our quality standard for each products.

Outgoing Quality Control (OQC) - Our QC team will 100% full inspection before it goes out for shipment.

Proper Quarantine procedure - For those products got rejected to pass the quality control, they will specially marked and dispose.

7. Good after sales services

8. Passed IATF16949:2016 and provide SGS/RoHS certification if needed.

FAQ

Hot Searches