- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZX

-

Model Number:

-

frp rock bolt

-

Diameter:

-

3-40mm, 16.18.20.22.24.27.30.32 mm

-

Product name:

-

Supply full-thread fiberglass frp rock bolts used for coal mine

-

Keyword:

-

frp rock bolt

-

Package:

-

Steel Strap or steel wire

-

Usage:

-

coal mine underground projects

-

survice:

-

within 24 hours

-

length:

-

as customers requirement

-

accessories:

-

plate & nut (frp or plastic)

-

Delivery time:

-

10-25 Days

-

Application:

-

Mining

Quick Details

-

System of Measurement:

-

Metric

-

Material:

-

frp

-

Capacity:

-

≥90KN

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZX

-

Model Number:

-

frp rock bolt

-

Diameter:

-

3-40mm, 16.18.20.22.24.27.30.32 mm

-

Product name:

-

Supply full-thread fiberglass frp rock bolts used for coal mine

-

Keyword:

-

frp rock bolt

-

Package:

-

Steel Strap or steel wire

-

Usage:

-

coal mine underground projects

-

survice:

-

within 24 hours

-

length:

-

as customers requirement

-

accessories:

-

plate & nut (frp or plastic)

-

Delivery time:

-

10-25 Days

-

Application:

-

Mining

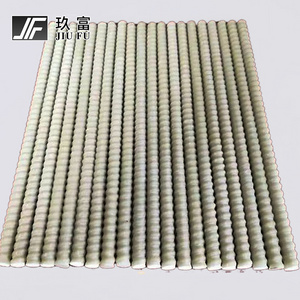

Supply full-thread fiberglass frp rock bolts used for coal mine:

1. Diameter Size(mm): 16.18.20.22.24.27.30.32 mm ( Outer diameter )

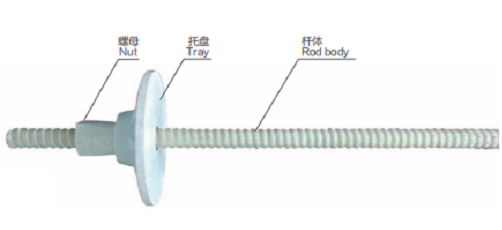

2. Accessories: tray & nut ( frp material or plastic)

3. Material & Characteristics: FRP rock bolt is formed by glass fiber yarn, resin and curing agent after extrusion, drawing and high temperature curing. High tensile strength, easy to cut, no damage to the cutting teeth, no spark, safe mining high efficiency, light weight, high corrosion resistance, flame retardant, antistatic performance, long-term support and other characteristics.

4. Installation Method:

-

Drilling with a bolt drill, after the completion, take out the drill pipe and push the resin capsule into the hole with the rock bolt;

-

Screw on the FRP tray and nut;

-

Screw the anchor to the end of the rock bolts, then insert the bayonet of the anchor into the drill link sleeve of the anchor drill to drill the resin capsule into the rock bolt hole;

-

Use the top of the rock bolt to withstand the resin capsule. At this time, the anchor rig is driven to push the leg to make the ascending motion, and the rig motor does not rotate, andthe resin capsule is pushed into the bottom of the hole;

-

When the motor drilling machine is started to rotate, the rock bolt rotates while stirring andstirringthe resin capsule. When the frp rock bolts is pushed to the bottom of the hole, thedrilling machine stops rising, and the drilling machine rotates and stirs the resin capsulerapidly. The stirring time is generally 10- 15S, that is, the drilling rig is closed. After resincapsules curing, unscrew the bolt mounter while lowering the rig, the frp rock bolt is installed.

5. Type of grout : Resin capsule or cement grout.

6. Application: M ainly used for the support of coal mine rock roadway, semi-coal rock roadway, coal wall, surrounding rock surface, slope anchoring and other underground projects.