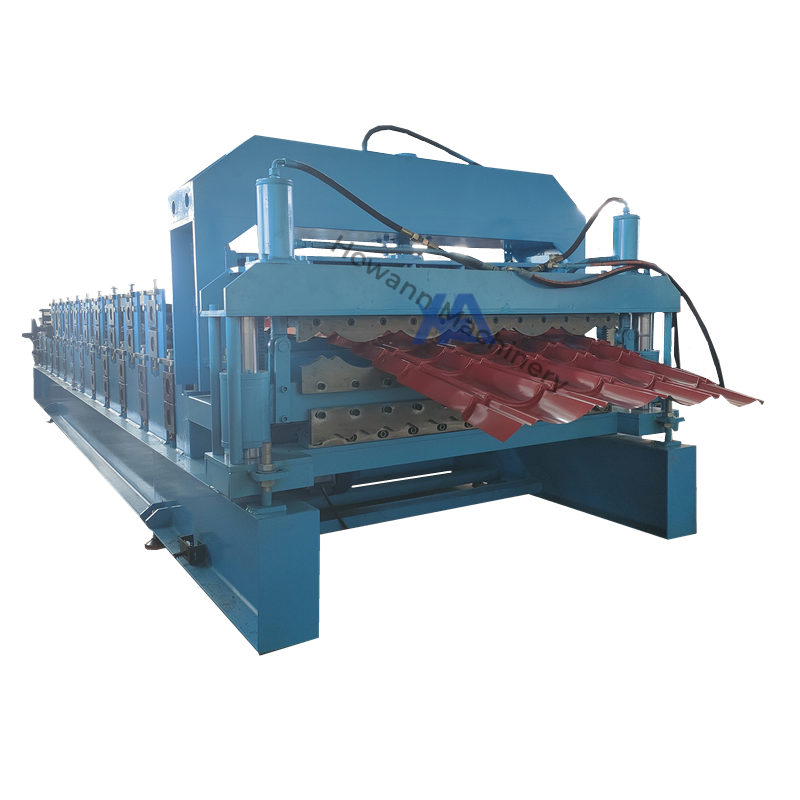

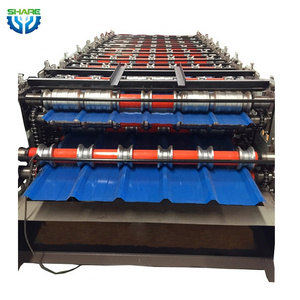

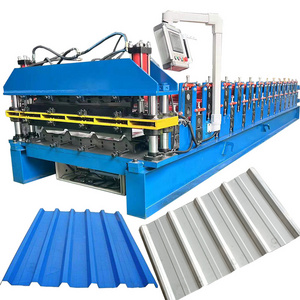

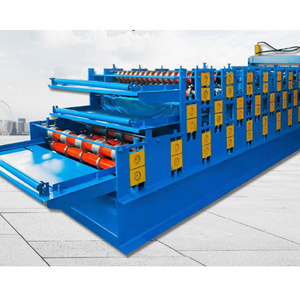

This kind of machine make two types of tile together perfectly, it has reasonable structure, beautiful appearance, with advantage of saving space, easy operate and especially welcomed by the customer with limit area or site.

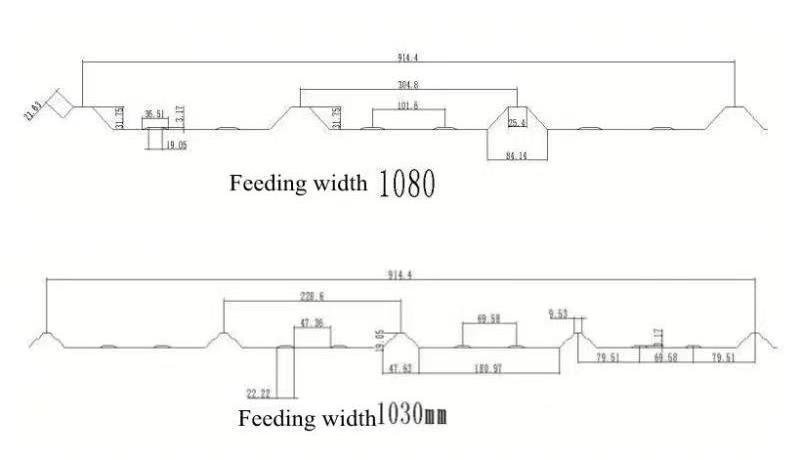

As there are various shapes of roofing panels, we provide you with a custom service.