- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JINHUA

-

Model Number:

-

1201AB

-

Type:

-

Liquid Glue

-

Color:

-

Clear

-

Shelf life:

-

6 Months

-

Certificate:

-

ROHS,REACH, PAHS, ASTM, EN-71

-

Mixing Ratio:

-

A:B=1:1

-

Lead Time:

-

3days

Quick Details

-

CAS No.:

-

38891-59-7

-

Other Names:

-

1201AB

-

EINECS No.:

-

500-033-5

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JINHUA

-

Model Number:

-

1201AB

-

Type:

-

Liquid Glue

-

Color:

-

Clear

-

Shelf life:

-

6 Months

-

Certificate:

-

ROHS,REACH, PAHS, ASTM, EN-71

-

Mixing Ratio:

-

A:B=1:1

-

Lead Time:

-

3days

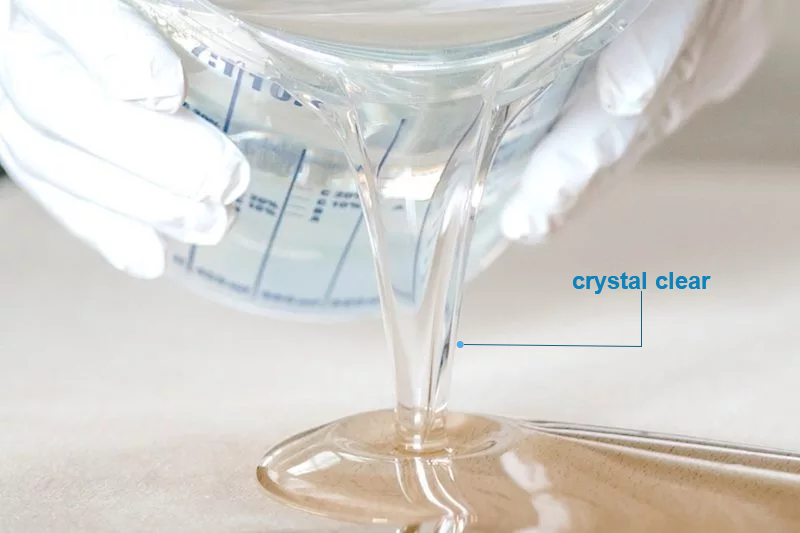

1.JINHUA clear and transparent epoxy resin AB glue made from basic pure resin and do well in adhesive.

2.Good at UV and yellow resistance,self leveling,without bubble,high brightness.

3.Can be cured at nomal temperature or by heating.

4.Clear,low viscosity,nature defoaming, super transprency and good performance after mixed.

5.Can get any color you want by add pigments.

6.Easy to clean and repair.

7.No ripple,bright in surface,odourless,eco-friendly,nontoxic,waterproof and so on.

Certificate

Properties before Hardening

|

Part

|

1201A

|

1201B

|

|

|

Color

|

Transparent

|

Transparent

|

|

|

Specific gravity

|

1

|

1

|

|

|

Viscosity (25℃)

|

4000-8000CPS

|

50 MAXCPS

|

|

|

Mixing ratio

|

A: B = 1:1(weight ratio)

|

|

|

|

Hardening conditions

|

25 ℃×8H to 10H or 55℃×1.5H (2 g)

|

|

|

|

Usable time

|

25℃×40min (100g)

|

|

|

Operation

1.Weigh A and B glue according to the given weight ratio into the prepared cleaned container, fully mixed the mixture again the container wall by clockwise, place it along for 3 to 5 minutes, and then it can be used.

2.Take the glue according to the usable time and dosage of mixture to avoid wasting. When the temperature is below 15 ℃, please heat A glue to 30 ℃ first and then mix it to the B glue (A glue will be thicken in low temperature ); The glue must be sealed lid after use to avoid rejection caused by moisture absorption.

3.When the relative humidity is higher than 85%, the surface of the cured mixture will absorb moisture in the air, and form a layer of white mist in the surface, so when the relative humidity is higher than 85%, is not suitable for room temperature curing, suggest to use the heat curing.

Caution

1,The operating environment should be ventilate and should keep away from fire. Closely sealed after use.

2, Avoid eye contact, in case of contact, wash with plenty of water and get medical attention immediately.

3, If contact skin, wrap with clean cloth or paper, and wash it with water and soap.

4, Keep away from children.

5, Please take a trial before application to avoid usage mistake.

1, Do Jinhua has MSDS for shipment?

Yes, we do have MSDS for shipment all all our epoxy and PU resin.

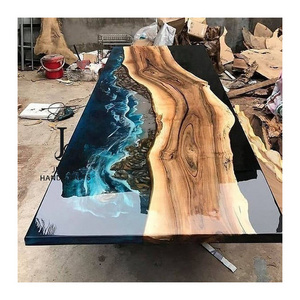

2, Why there is crack between resin and wood after curing ?

Because the handling way is not right or the model of deep pour resin is not so suitable.

The solution is :

1) Do pretreatment before pour resin ,

2) consider to choose a slower cure resin or reduce thickness per layer of pouring ;

3, Why there is wrinkled, uneven and wavy on top of the table after cure when use other supplier’s products ?

It depends on the quality and formula. Our factory offers high quality products , there will be no problem if use our products.

4,Why it is yellowing or cracking after river table cured ?

A: It releases too high heat during the resin curing . The solution will be :

1) control the temperature of the curing environment,

2) reduce thickness per layer of pouring ,

3) choose a slower cure and deeper pour resin ;

5,Do you have manual instruction videos ?

Yes we have ,pls kindly contact our sales to send you.

6,If we have other special performance to be added into products ,will you customize for us?

Yes we can , we have professional R& D team , who can do a model as per clients requirements, we can deliver new samples within 3 days;

5kgs per bottle; 20kgs per carton,20kgs per barrel ,200kgs per barrel.