- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BS

-

Dimensions(L*W*H):

-

2950*2640*2107mm

-

Weight:

-

4000 KG

-

Max. Print Area:

-

25*260mm

-

Application:

-

Screen Printing

-

Type:

-

Silk Screen Machine

-

Product name:

-

Glass Bottle Printing Machine

-

Application area:

-

cosmetic plant

-

Printing type:

-

Automtic Screen Printing Machine

-

AIR PRESSURE:

-

0.6-0.8Mpa

-

Printing color:

-

Multi Color Optional

-

Keywords:

-

Glass Bottle Printing Machine

-

Printing speed:

-

2700PCS/Hr

-

Operation:

-

Automatic Operation

Quick Details

-

Condition:

-

New

-

Color & Page:

-

Multicolor

-

Voltage:

-

AC380V 50/60HZ 30KW

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BS

-

Dimensions(L*W*H):

-

2950*2640*2107mm

-

Weight:

-

4000 KG

-

Max. Print Area:

-

25*260mm

-

Application:

-

Screen Printing

-

Type:

-

Silk Screen Machine

-

Product name:

-

Glass Bottle Printing Machine

-

Application area:

-

cosmetic plant

-

Printing type:

-

Automtic Screen Printing Machine

-

AIR PRESSURE:

-

0.6-0.8Mpa

-

Printing color:

-

Multi Color Optional

-

Keywords:

-

Glass Bottle Printing Machine

-

Printing speed:

-

2700PCS/Hr

-

Operation:

-

Automatic Operation

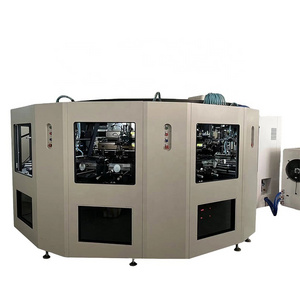

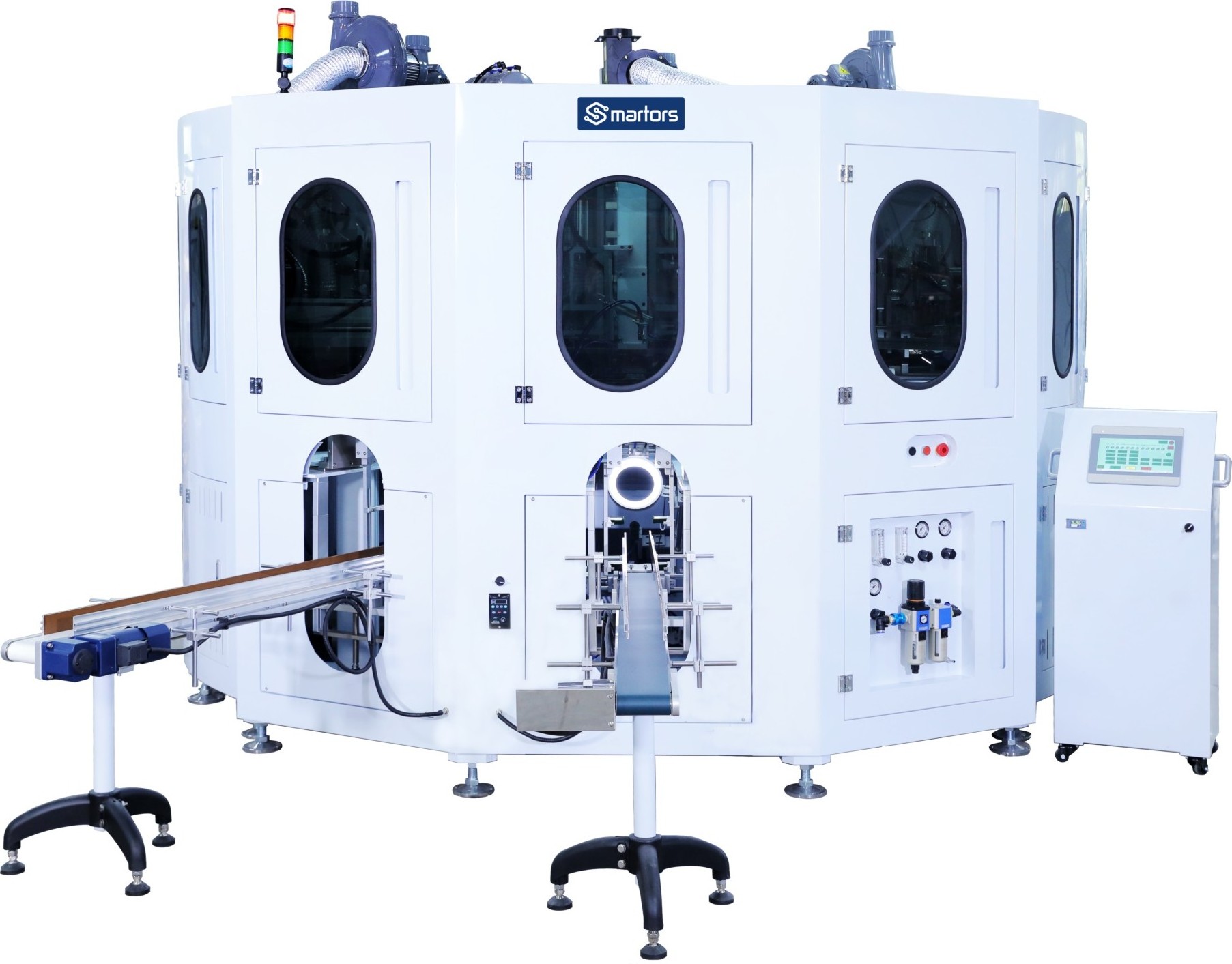

Specification

| Device name | automatic silk printing machine |

| Machine Model | BSF20 |

| Printing area | 20-120MM*60-280MM |

| Printing speed | 2200PCS/Hr,3600PCS/Hr |

| Air pressure | 0.6-0.8MPA |

| UV lamp power | 5kw |

| Equipment size | 2950*2640*2107mm |

| Equipment power | AC 380V 50/60 HZ 25KW |

| Machine weight | 4000kg |

Description

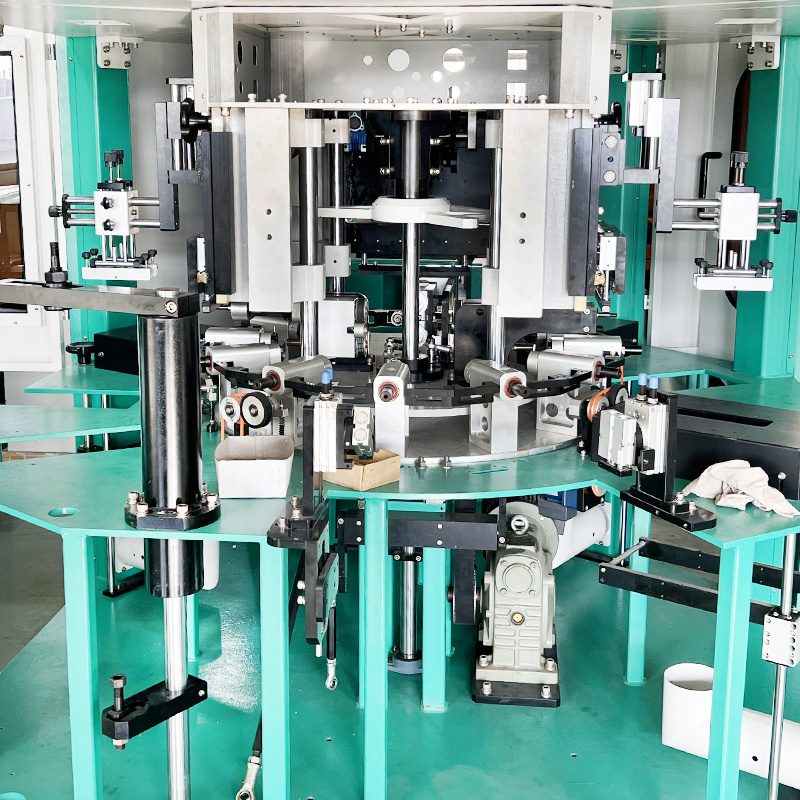

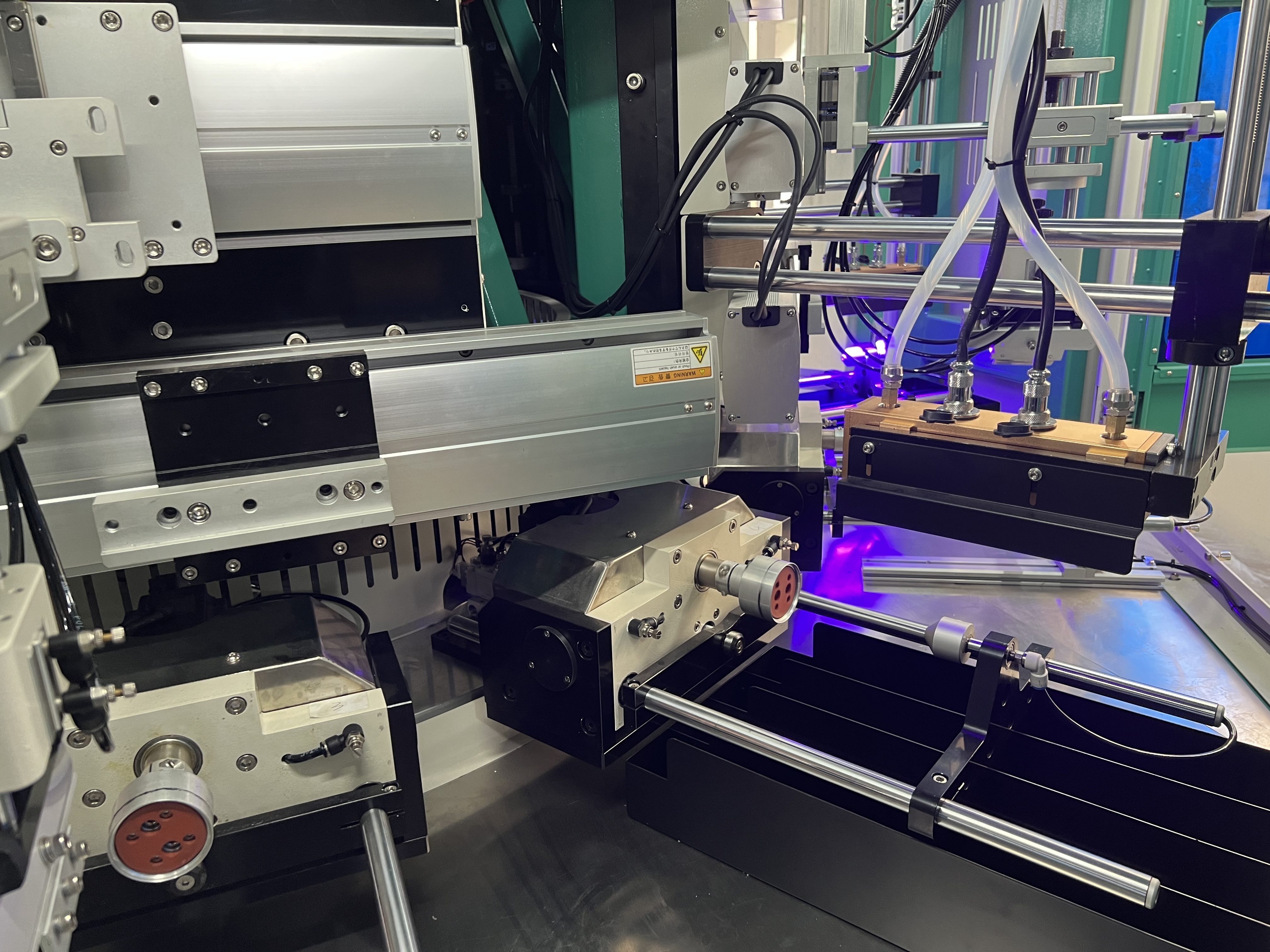

An automatic silk screen printing machine is a specialized industrial printing machine that is used to apply ink or other materials onto a substrate using a silk screen stencil. It is fully automated, which means it requires minimal manual operation, and is capable of high-volume production.

In an automatic silk screen printing machine, the substrate is fed into the machine and secured onto a printing platen. The platen then moves automatically to the printing station where the silk screen stencil is lowered onto the substrate. Ink is applied to the stencil and a squeegee moves across the stencil to force the ink through the areas of the stencil that are open.

The machine is programmed to repeat the printing process automatically, with each substrate being printed identically. The ink is dried or cured using heat or UV light, depending on the ink type, and the substrate is then ejected from the machine.

Product Detals