- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Non-Epoxy

-

Color:

-

Natural

-

Application:

-

permeate carrier

-

Usage:

-

Pure Water flow guide

-

Width:

-

280mm(±2

-

Thickness:

-

0.25mm(±0.02)

-

Weight:

-

85g/㎡(±10

-

Weight Loss , Boiling Water:

-

5‰

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LONGSHENG

-

Weight (KG):

-

100 kg

-

Material:

-

Non-Epoxy

-

Color:

-

Natural

-

Application:

-

permeate carrier

-

Usage:

-

Pure Water flow guide

-

Width:

-

280mm(±2

-

Thickness:

-

0.25mm(±0.02)

-

Weight:

-

85g/㎡(±10

-

Weight Loss , Boiling Water:

-

5‰

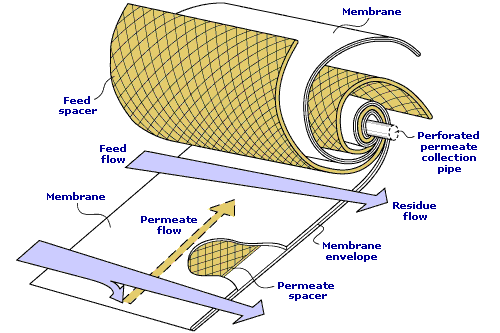

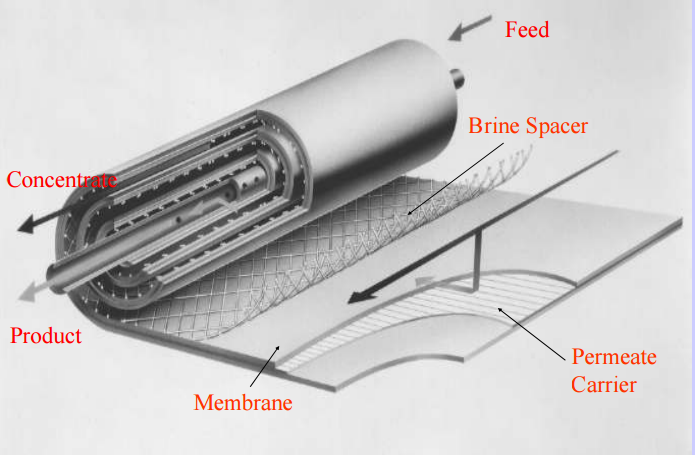

Product Application

Permeate spacer/Channel Spacer - is also known as a "permeate water carrier",or "mesh spacer". In the construction of a membrane element, the product channel spacer is placed between two layers of the flat sheet membrane. This spacer is made using a knit fabric called Tricot, and is used to prevent the RO membrane from closing-off on itself under the high pressure of operation. Permeate water will flow in a spiral path across the product channel spacer into the product collection tube.

Main Features

Provides channel to carry permeate away from the membrane and to the holes in the permeate tube .

Must be capable of withstanding the compressive forces resulting from the operating pressures of the system

Tricot knit polyester fabric with advanced technology.

FOOD GRADE CERFIFICATION OR NO HARMFUL SUBSTANTIAL REPORT AVAILABLE

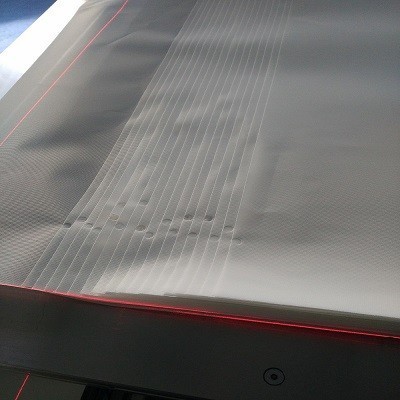

tricot welded toghether

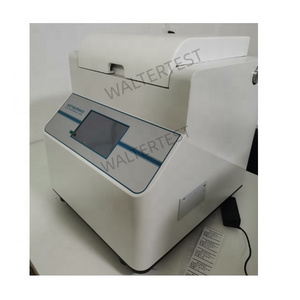

the permeate spacers can be bonded with each other by ultrasonic welding device to avoid trouble during rolling for process for industrial membrane.

the membrane structure for reference

The permeate water, once filtered by the RO membrane, flows into and along a material called a“permeate carrier” (sometimes called a “permeate spacer”) – this can be a type of knitted or “tricot weave” polyester material. The permeate carrier is welded to a perforated core called a permeate collection tube (or permeate tube). This permeate carrier is sandwiched between RO membrane above and below it, and the sandwich is sealed on three edges by glue or ultrasonically to form a “membrane

leaf.” By the time the water passes through the embrane and goes into the permeate carrier it would be very clean.

Above picture show how the permeate carrier applied by rolling machine for domestic purpose..

the with of tricot roll can be customerized as per customers' request, for example the model 1812, the width is normally 280mm.

1) the permeate spacer roll can directely applied to the automatic cutting and folding machine to prepare for the following memrbane rolling process.

2) the tension of the feed spacer is adjustable by tensioner through changing the input on the operation panel.

3) welding and cutting smoothly processed without burr or sharp corner that may damage the memrbane in the folding operation.

4) high procution rate and hygiene grade ensurable due to little human involved in the cutting process.

Pre-Sales Service

we offer our customer with detialed information about the machines both in terms of technical and commercial to ensure customer fully understand our machine for further smooth coorperation.

After-Sales Service

Technicains available for try running at customer's factory at request of customer ,all related cost borne by user(include round air tickets, hotel,food,salary usd80/day/person).

width and the length per roll can be customerized as customer's requirement.