- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CAMEL

-

Voltage:

-

380v 50hz 3phase(or customized)

-

Dimension(L*W*H):

-

25000*1500*2500mm

-

Power (kW):

-

75

-

Weight:

-

5000 KG

-

Usage:

-

Plastic PVC pipe extrusion

-

Input Material:

-

Pvc resin, CaCO3, and additives

-

Pipe size:

-

16-630mm

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB, Delta, SINEE, etc.

-

Temperature controller:

-

OMRON/RKC

-

Gear box:

-

JC Brand/Guomao Brand

-

Electric components:

-

Schneider/Siemens/Delixi

-

Machine color:

-

White and blue or customized

-

Installed power:

-

150kw

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CAMEL

-

Voltage:

-

380v 50hz 3phase(or customized)

-

Dimension(L*W*H):

-

25000*1500*2500mm

-

Power (kW):

-

75

-

Weight:

-

5000 KG

-

Usage:

-

Plastic PVC pipe extrusion

-

Input Material:

-

Pvc resin, CaCO3, and additives

-

Pipe size:

-

16-630mm

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB, Delta, SINEE, etc.

-

Temperature controller:

-

OMRON/RKC

-

Gear box:

-

JC Brand/Guomao Brand

-

Electric components:

-

Schneider/Siemens/Delixi

-

Machine color:

-

White and blue or customized

-

Installed power:

-

150kw

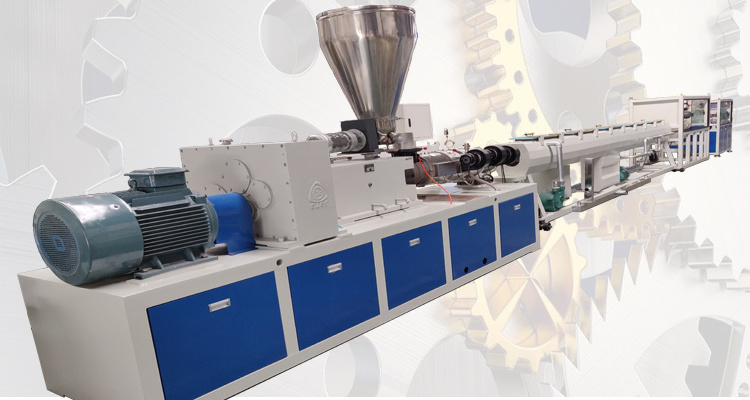

Products Description

PVC pipe extrusion line

Application:

The main electrics for PVC pipe extrusion machine adopt Siemens motor, Schneider contactor, ABB inverter, RKC/OMRON temperature controller.

It is mainly used in producing various diameters and wall-thickness of PVC pipes for agriculture and constructional plumbing, electrical conduit etc.

Can manufacture U-PVC, C-PVC, O-PVC pipe according to customer's requirements

Features

Our PVC pipe extrusion machine has features of low energy consumption, high output, stable running etc.

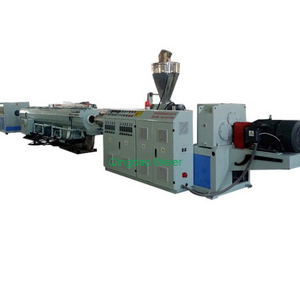

The standard PVC pipe extrusion machine include: material feeder, SJSZ series conic twin screw

extruder, mould, vacuum calibration tank, spray cooling tank(for big pipe), haul-off, cutter, stacker/automatic belling machine.

Our PVC pipe extrusion machine has features of low energy consumption, high output, stable running etc.

The standard PVC pipe extrusion machine include: material feeder, SJSZ series conic twin screw

extruder, mould, vacuum calibration tank, spray cooling tank(for big pipe), haul-off, cutter, stacker/automatic belling machine.

Clients also can choose double/four PVC pipe extrusion line to make small size PVC pipes.

The main electrics for PVC pipe extrusion machine adopt Siemens motor, Schneider contactor, ABB inverter, RKC/OMRON temperature controller.

Details Images

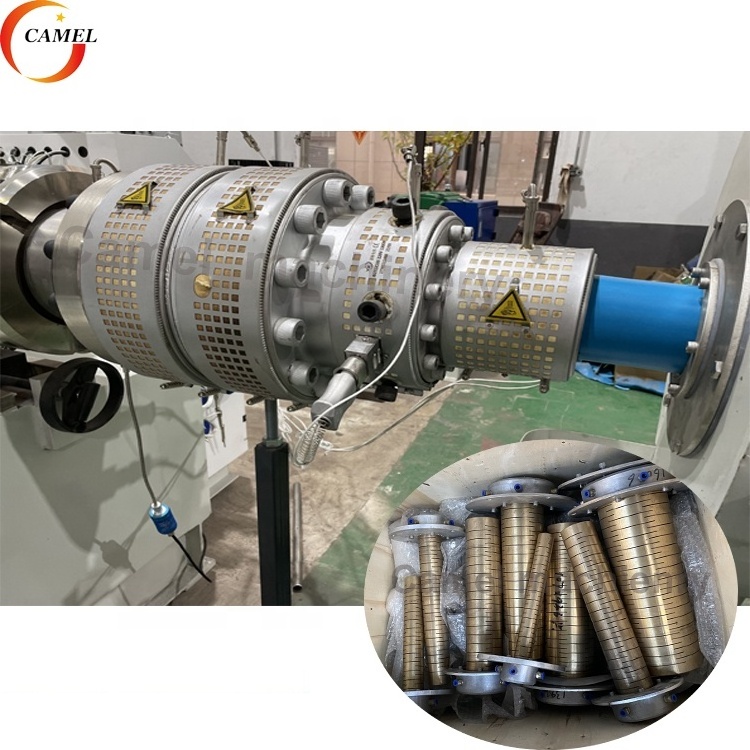

Conical twin screw extruder

Mould

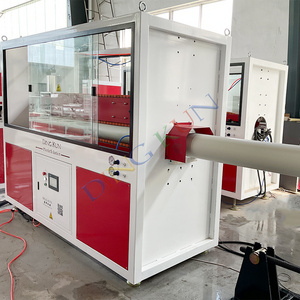

Vacuum calibration tank

Spray cooling tank(for big pipe)

Printer (

optional

)

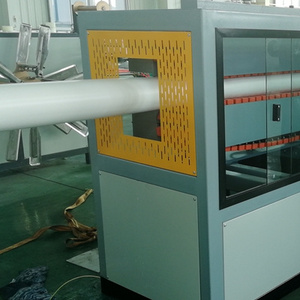

Haul-off

Cutter

Automatic belling machine

Technical data:

|

Diameter range

(mm)

|

Extruder Model

|

Main motor power

(KW)

|

Max. Capacity

(KG/H)

|

Max. Haul off speed

|

|

16-40 Dual

|

SJSZ51/105

|

18.5 AC

|

150

|

10(m/min.)

|

|

20-63 Dual

|

SJSZ65/132

|

37 AC

|

250

|

15(m/min.)

|

|

20-63

|

SJSZ51/105

|

18.5 AC

|

120

|

15(m/min.)

|

|

50-160

|

SJSZ65/132

|

37 AC

|

250

|

8(m/min.)

|

|

75-160 Dual

|

SJSZ80/188

|

110 AC

|

450

|

6(m/min.)

|

|

63-200

|

SJSZ65/132

|

37 AC

|

250

|

3.5(m/min.)

|

|

110-315

|

SJSZ80/156

|

55 AC

|

450

|

3(m/min.)

|

|

315-630

|

SJSZ92/188

|

110 AC

|

800

|

2(m/min.)

|

Hot Searches