- Product Details

- {{item.text}}

Quick Details

-

Function:

-

Chalk making

-

Usage:

-

Chalk Maker

-

Voltage:

-

220V

-

Capacity:

-

2000-40000

-

Color:

-

Accept Customer Deisgn

-

Mould size:

-

400 pcs/mould

-

Chalk size:

-

10*8*75mm

-

Machine size:

-

530*380*340mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Name:

-

Dustless chalk making machine

-

Application:

-

School

-

Function:

-

Chalk making

-

Usage:

-

Chalk Maker

-

Voltage:

-

220V

-

Capacity:

-

2000-40000

-

Color:

-

Accept Customer Deisgn

-

Mould size:

-

400 pcs/mould

-

Chalk size:

-

10*8*75mm

-

Machine size:

-

530*380*340mm

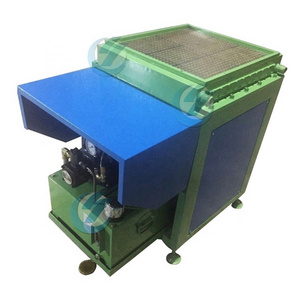

Dustless School Chalk Machine/Chalk Making Machine/School Chalk Mold Maker Machine

Main Features of Chalk Making Machine

Its feature lies in that it is composed of the water meter at the upper part of the frame, the material meter at the middle part of the agitator and the intermittent rotary table at the lower part.

1.Free of dust

2. Great treatment ability

3. Wearable- resistant and longevity/durable

Chalk production process

1. Mold evenly brush oil, brush back and forth with a wide brush, brush the new mold should be more oil.

2. The mold plate moving up and down a few times, the screw top and the bottom plate comes into contact.

3. Turn on the water, turn on the water with a movable foot switch pedal to pedal in the end, until the water in the water last. (First mold first feed, add water)

4. Addition, the quantitative good gypsum powder into the mixing bucket.

5. Mixing, stirring for 10-20 seconds to start the motor.

6. Put the pulp, put a good brush oil stirred to die bottom of the barrel, hit the switch to open the pulp slurry was stirred well into the mold until the stream last.

7. Calibrating with a plastic scraper to scrape the pulp mold hole, scrape out the remaining pulp mold mouth gelling.

8. A mold, a new mold die not too late. Chalk can feel a little hard to top 2-5 mm, 1 to 2 minutes over again ejection.

Technical Parameters of Chalk Machine

|

Model |

ASL-CM-200 |

|

Capacity |

2000pcs/h |

|

Voltage |

220v |

|

Volume |

0.07m³ |

|

Chalk size |

10*8*75mm |

|

Package dimension |

530*380*340mm |

|

Weight |

28kg |

Detail Photos of Chalk Machine