- Product Details

- {{item.text}}

Quick Details

-

Drilling Speed:

-

790-1400R/MIN

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

DL Tapping Drilling Machine

-

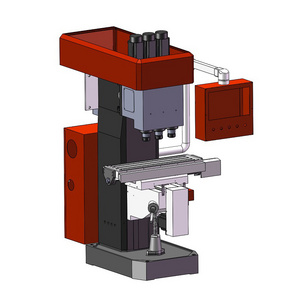

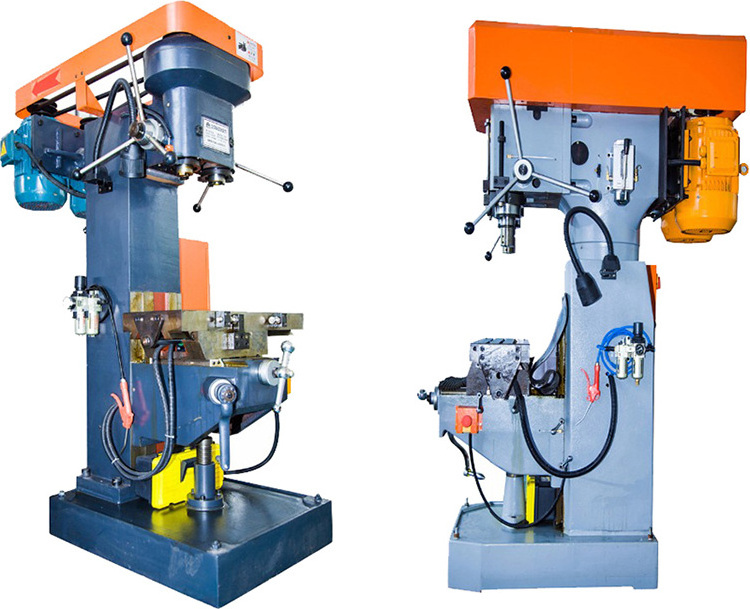

Model Number:

-

DL-ZS4132*2

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

1200*610*1450mm

-

Power (kW):

-

3

-

Weight (KG):

-

600 KG

-

Marketing Type:

-

drilling machine

-

Machine type:

-

Tapping And Drilling Machine

-

Biggest drilling diameter:

-

50mm

-

Biggest tapping diameter:

-

45mm

-

drilling power:

-

3kw/4p

-

tapping power:

-

2.2kw/6p

-

Size of working plate:

-

500x225mm

-

Drilling speed:

-

790-1200R/MIN

-

Tapping speed:

-

435-620R/MIN

-

Go up and down distance:

-

350mm

-

Application:

-

Auto Parts,plumbing fittings,metal workpieces

Quick Details

-

type:

-

Bench Drilling Machine

-

Max. Drilling Dia. (mm):

-

90 mm

-

Range of Spindle Speed(r.p.m):

-

10 - 1400 r.p.m

-

Drilling Speed:

-

790-1400R/MIN

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

DL Tapping Drilling Machine

-

Model Number:

-

DL-ZS4132*2

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

1200*610*1450mm

-

Power (kW):

-

3

-

Weight (KG):

-

600 KG

-

Marketing Type:

-

drilling machine

-

Machine type:

-

Tapping And Drilling Machine

-

Biggest drilling diameter:

-

50mm

-

Biggest tapping diameter:

-

45mm

-

drilling power:

-

3kw/4p

-

tapping power:

-

2.2kw/6p

-

Size of working plate:

-

500x225mm

-

Drilling speed:

-

790-1200R/MIN

-

Tapping speed:

-

435-620R/MIN

-

Go up and down distance:

-

350mm

-

Application:

-

Auto Parts,plumbing fittings,metal workpieces

2.Both the left and right workbench adopt cylinder for minimal vibration.

3.Clamp system uses cylinder to hold the mould for fast fixing.

4.Slider system adopts guide way ultrasonic frequency quenching and lubrication system for better capability.

5.Manually oil injector, manually feeding lubricating oil before and after the processing can maintain the drilling and tapping machine in good function.

6.Tapping main shaft performs self-acting feed by leading screw so as to realize tapping and ensure its feeding stability.

|

Technical Parameter

|

|

|

||

|

Type

|

ZS4132*2

|

ZS4150*2

|

||

|

Performance Dimension

|

1200*610*1450(mm)

|

1390*1110*1750(mm)

|

||

|

Machine Weight

|

600KG

|

1200KG

|

||

|

Worktable Size

|

600*230mm

|

800*230mm

|

||

|

Worktable Stoke Length

|

150mm

|

240mm

|

||

|

Main Spindles number

|

2 unit

|

2 unit

|

||

|

Spindle Forms

|

NT30

|

MT4

|

||

|

Spindle Power

|

3KW/4P

|

3KW/6P

|

||

|

Spindle Rotating Speed

|

left: 880/1400 (r/min)

right: 880/1400 (r/min)

|

left: 675 (r/min)

right: 1000/675 (r/min)

|

||

|

Spindle Outer Diameter

|

86mm

|

90mm

|

||

On Line Talk

For different customer has different requirements about machine,welcome to contact us to make a further discussion!

Customers Visit

Production Workshop

1. Before payment

a. We will provide our best professional for the most suitable SPM machine.

b. Free professional design for each customer especially. Support sample testing.

c. Welcome to visit our factory.

2. After-Sales Service

a. After sending,

we will track the machine for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

b. We also can provide engineers / technicians to buyer’s factory if client requirement, train the drilling tapping machine works well, and also supply the technical support for free and spare parts at good price always.

3. Guarantee Period

1 year. During the guarantee period, the seller guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair, Seller can send the technician to buyer's factory on seller's account if problem is serious and can't be solved by buyer.

4. Payment Terms

T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

5. Lead Time

Our delivery time generally it is 30-40 days if the machines are in stock, or it is 70-90 days if the machines are not in stock, it is according to quantity.

Q1. Where is your factory located ? How can I visit it ?

A : Our factory is located in Quanzhou city,Fujian province,China.You can fly to Jinjiang or Xiamen air port,we will pick you up.

Q2. Are you produce machine’s specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings. Usually one machine have different molds and fixtures like metal polishing machine,die casting machine.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock, but the customers have to pay the sample shipping cost.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.