- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DECOK

-

Model Number:

-

solid aluminium ball

-

Product:

-

solid aluminium ball

-

Experience:

-

26 years steel ball manufacture history

-

Special Types:

-

lid/nonporous

-

Finishing:

-

smooth/polish finish

-

Grade:

-

G100 G200 G500 G1000

-

Tolerance:

-

+/-0.0025~0.02mm refers to grade

-

Hardness:

-

20-30 HV0.5

-

Size Ranges:

-

0.5~50 mm

-

Product shape:

-

sphercial

-

Material standard:

-

Pure aluminum 1** series

Quick Details

-

Applicable Industries:

-

Building Material Shops, Machinery Repair Shops, Home Use, Retail, Construction works , Other

-

Material:

-

aluminum

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DECOK

-

Model Number:

-

solid aluminium ball

-

Product:

-

solid aluminium ball

-

Experience:

-

26 years steel ball manufacture history

-

Special Types:

-

lid/nonporous

-

Finishing:

-

smooth/polish finish

-

Grade:

-

G100 G200 G500 G1000

-

Tolerance:

-

+/-0.0025~0.02mm refers to grade

-

Hardness:

-

20-30 HV0.5

-

Size Ranges:

-

0.5~50 mm

-

Product shape:

-

sphercial

-

Material standard:

-

Pure aluminum 1** series

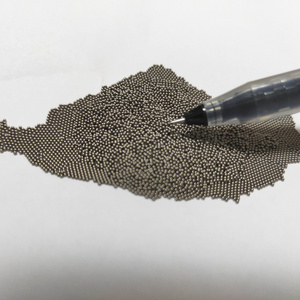

0.5mm 0.6mm 0.7mm 0.8mm Pure Aluminum Ball Solid Aluminium Spheres

1-Basic information of pure aluminum ball

|

Diameter |

0.5mm~50mm |

|

Precision grade |

G100 -200-500 |

|

Hardness |

20-30 HV0.5 |

|

Surface |

smooth finish |

|

Special types |

solid |

2-Features of pure aluminum balls:

Commercially pure aluminum balls

,light balls in silvery white color featured by good corrosion and wear resistance, very good surface finishing. Balls are not heat treated. Balls can be provided in the passivated conditions.

3-Applications of pure aluminum spheres:

Special bearings and valves, sealing elements (crushed balls), they are used in automotive industry (safety devices), aviation and aerospace industry, electronic industry, welding processes and often used as closures.

4-Chemical Analysis:

|

Al 99.7 max % Si 0.2 max % Fe 0.25 max % Mn 0.03 max % Cu 0.03 max % Ti 0.03 max % V 0.05 max % Mg 0.03 max % Zn 0.07 max % |

5-More informations starts from here.

How a ball is made?

Wire coil:

Steel wire of specific material and size were inspected for correctness.

Cutting:

The wire is cut into required length.

Forging/heading:

Spherical shapes between dies are formed.

Deflashing:

The flash line along the circumference is removed.

Heat treatment:

Carbon steel and chrome steel balls are through hardened.

Cleaning/descaling:

Basic surface cleaning is done.

Hard grinding / filing:

An exacting process to achieve required sphericity and size of the steel ball.

Lapping:

The final surface finish is acquired through this process.

Polishing / bunishing:

Surface luster, working hardening, higher product life is achieved.

Passivation:

Carryover iron and other contaminants are removed and a surface film prevents atmospheric and water corrosion on stainless steel balls.

Inspection:

For surface finish,size and tolerance.

Rust preventive oil:

Applied on carbon and chrome steel balls to save from rusting and corrosion.

Package:

Poly bag and carton of bulk packaging.

Polybag and woven bag of bulk packaging.

Polybag and wooden case of bluk packaging.

Or as per required.

Company profile:

ECOK STEEL BALL CO., LTD. was founded in 2000 and is well known top manufacturer in the production of steel ballls in China.

The specific power of DECOK is the wide range of sizes,metal materials and grades completely available in one source of supply.

The Factory is employing 28 people in Guangzhou Marketing Office and the Shandong facility is employing 218 people and covers 6,000 square meters including headquarters, workshop,warehouse,quality control department.

The QC Dept is equipped with high tech control machines testing all technical features of each batch products.

Our warehouse is constantly filled with more than 3000 TONS of finished goods in order to satisfy in the shortest terms the requirements of our customers.

DECOK goal is to guarantee all our customers with the most appropriate goods in best price.

Welcome to visit DECOK at your proper time.

|

Puduct |

Steel ball |

|

Material |

1015 1010 low carbon steel 201 302 304 316 420 430 440 stainless steel 52100 chrome steel H62 brass T2 copper |

|

Grade |

G8 G16 G40 G60 G100 G200 G500 G1000 |

|

Precision |

G8:±0 μm G16: ±0.4 μm G40: ± 1 μm G60: ±2 μm G100: ± 2.5μm G200: ± 5μm G500 : ±10 μm G1000 : ±20 μm |

|

Hardness |

21HRC 25HRC 28HRC 30HRC 58HRC 60HRC 62HRC 66HRC 68HRC |

|

Metric sizes |

0.35mm 0.5mm 0.8mm 1mm 1.2mm 1.5mm 1.588mm 1.7mm 1.8mm 1.9mm 2mm 2.381mm 2.5mm 3mm 3.175mm 3.5mm 3.96mm 4mm 4.76mm 5mm 5.556mm 6mm 6.35mm 6.8mm 7mm 7.144mm 7.938mm 8mm 8.5mm 8.7mm 9mm 9.525mm 10mm 11mm 12mm 12.7mm 13.5mm 14mm 14.288mm 15mm 15.875mm 17.4mm 18mm 19.05mm 20mm 22mm 25mm 25.4mm 30mm 35mm 38mm 40mm 45mm 50mm 50.8mm 100mm 150mm 200mm |

|

Size in inches |

1/32 1/16 3/32 1/8 5/32 3/16 7/32 1/4 9/32 5/16 11/32 3/8 7/16 1/2 17/32 9/16 5/8 11/16 3/4 7/8 1 1-1/16 1-1/8 1-1/4 1-5/16 1-3/8 1-1/2 1-3/4 2 2-1/4 2-1/2 2-3/4 3 4 6 8 |

|

Processing(OEM) |

Drilled Threaded Hollow Plated |

PS:1inch=25.4mm 1mm=1000um