- Product Details

- {{item.text}}

Quick Details

-

Use:

-

mixer

-

Place of Origin:

-

Henan, China

-

Power:

-

2.2kw

-

Production line:

-

could be offered

-

Automatic:

-

semi-automatic,automatic

-

Driven power:

-

electric

-

Capacity:

-

time/1000kg

-

Package:

-

Wooden case Package

-

Voltage:

-

380V Custmoer's Demand

-

Brand:

-

Ainuok

-

Batch time:

-

5 min/batch

-

Mixing type:

-

Rotate Mixing

Quick Details

-

Weight (KG):

-

230

-

Core Components:

-

other

-

Type:

-

mushroom mixer

-

Use:

-

mixer

-

Place of Origin:

-

Henan, China

-

Power:

-

2.2kw

-

Production line:

-

could be offered

-

Automatic:

-

semi-automatic,automatic

-

Driven power:

-

electric

-

Capacity:

-

time/1000kg

-

Package:

-

Wooden case Package

-

Voltage:

-

380V Custmoer's Demand

-

Brand:

-

Ainuok

-

Batch time:

-

5 min/batch

-

Mixing type:

-

Rotate Mixing

Product Description

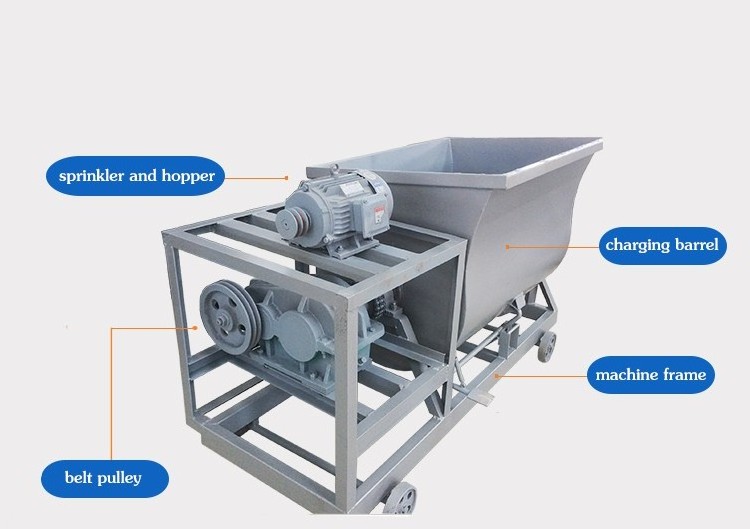

Factory Supply Mixing Mushroom Substrate Horizontal mixer machine Corn mixer machine

Mixing machine

used for mixing raw material for better cultivated high quality mushroom.

* Mixing time :5-15 min/batch

*Mixer Volume capacity range 2.5-22 m3 ,accept customized make.

*Can equipped water measure meter.

*With safe lock device, Automatic Bucket discharge.

*Equipped wheels,can move around.

Model type

|

Model number

|

Specification

|

Power

|

Capacity

|

Weight

|

|

AKH-100

|

650×900×1100MM

|

2.2kw/3phase

|

80kg/time

|

260kg

|

|

AKH-150

|

2150*900*1100MM

|

3kw/3phase

|

130kg/time

|

330kg

|

|

AKH-200

|

2750*900*1100MM

|

4kw/3phase

|

180kg/time

|

380kg

|

|

AKH-101

|

2800*900*1100MM

|

5.5kw/3phase

|

220kg/time

|

480kg

|

|

AKH-121

|

2900*1300*1600MM

|

7.5kw/3phase

|

350kg/time

|

500kg

|

Advantages

1.Greatly improving the quality of mixed material.

2.Makes cultivate medium with uniform humidity and nutrition distribution.

3.Increase the production yield.

4.Mixer Discharge automatically

5.Saving labor, improve working efficient.

6.Can matched with the bagging machine into production line.

7.Install wheels can moving to work in different places.

Detail

Feature

Large mixer adopts big gear, reducer structure, effectively buffer the motor load, the auger is of positive and negative spiral structure, mixing evenly.

1.Suit for all kinds of crushed straw material, or powder, like sawdust, rice straw, corn stalk, corn cob, or other agriculture waste

2.It can add water when mixing according to need

3.Auto turn over discharge , save labor

4.Have wheels,can move easily in working area

Work site

Packing

Related Products

Our service

1. After-sale service:

We provide 12 months' warranty(After the warranty, we can provide life-long repair service).

2. Customization:

We make customized mushroom substrate mixing machine .

3. Design:

* Mechanical Design: We make a good mechanical design to ensure they can operate without

any frictions, so that it can have a long service life.

* If you have some special scenes in your mind, you can draw it down and we can produce the your picturesAlso, we can make the movie scenes!

* Inspection: we have a strict Quality Inspection Department, and every machine would be tested before delivery.

We will serve you online in 24 hours!!! You can contact with me if you have any problems.

Tel:0086-15637237667

Email:emily@ainuok.com

Wechat:15637237667

Whatsapp:008615637237667

Company Introuduction

Who We Are?

Anyang Ainuok is one leading Comprehensive company with own brand and after-service for projects related with mushroom cultivation equipment ,Waste mushroom substrate recycle machinery,company has passed the ISO9001 authentication , Standing on the international market. Our main products such as Crusher,Dryer,Mixer,Bag filling machine,PLC Bag filling production line,Charcoal Briquette and Pellet Production line etc.Agricultural Farm and Woodworking machinery.

We have a strong and agile team for purchase,tracking production, packing, delivery and after-sales, we have a dedicated team of specialists ready to serve for you.With our diverse product-line and expertise, we will help you make the right decision.

Anyang Ainuok is one leading Comprehensive company with own brand and after-service for projects related with mushroom cultivation equipment ,Waste mushroom substrate recycle machinery,company has passed the ISO9001 authentication , Standing on the international market. Our main products such as Crusher,Dryer,Mixer,Bag filling machine,PLC Bag filling production line,Charcoal Briquette and Pellet Production line etc.Agricultural Farm and Woodworking machinery.

We have a strong and agile team for purchase,tracking production, packing, delivery and after-sales, we have a dedicated team of specialists ready to serve for you.With our diverse product-line and expertise, we will help you make the right decision.

What We Do?

Supplying Crusher ,Dryer,Mixer for prepare mushroom substrate for mushroom cultivation.

Offering Bagging machine for filling bag for growing mushroom.

Guiding for Recycle processing waste mushroom substrate ,make waste into value.

Production wood crusher,briquette press,carbonization furnace to made wood charcoal.

Supplying Crusher ,Dryer,Mixer for prepare mushroom substrate for mushroom cultivation.

Offering Bagging machine for filling bag for growing mushroom.

Guiding for Recycle processing waste mushroom substrate ,make waste into value.

Production wood crusher,briquette press,carbonization furnace to made wood charcoal.

FAQ

Q1. What's your advantage? How to install?

1) We have 10 years of working experience. The real production plant of 200 workers has the most professional technology and team.

Price is more advantageous.

2) Provide installation videos, or arrange for engineers to communicate with you directly on installation methods.

3) We have overseas engineer services and can provide free training for on-site staff.

Q2. How long is your delivery time?

If there is stock, it usually takes 5-10 days. It takes 20-30 days to customize the equipment according to your requirements.

Q3:What if the machine is damaged?

One-year warranty and comprehensive after-sales service. After this period, we will charge a lower fee to maintain after-sales

service.

Q4: Service and Payment Terms ?

We usually accept T/T, L/C and 30% down payment for large equipment.

1) We have 10 years of working experience. The real production plant of 200 workers has the most professional technology and team.

Price is more advantageous.

2) Provide installation videos, or arrange for engineers to communicate with you directly on installation methods.

3) We have overseas engineer services and can provide free training for on-site staff.

Q2. How long is your delivery time?

If there is stock, it usually takes 5-10 days. It takes 20-30 days to customize the equipment according to your requirements.

Q3:What if the machine is damaged?

One-year warranty and comprehensive after-sales service. After this period, we will charge a lower fee to maintain after-sales

service.

Q4: Service and Payment Terms ?

We usually accept T/T, L/C and 30% down payment for large equipment.

Hot Searches