- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0-80KW(customizable)

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

3000 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

3BBL Beer Brewing Equipment

-

Application:

-

Restaurants, brewpub, brewery, bar, hotel

-

Function:

-

Beer Brewing

-

Material:

-

SUS304/SUS316/Copper

-

Keywords:

-

Two Vessel HLT Brewhouse

-

Capacity:

-

3BBL

-

Thickness:

-

Inner 3mm External 2mm

-

Heating way:

-

Steam Electric and direct fire

-

Control system:

-

Semi-automatic/Manual

Quick Details

-

Place of Origin:

-

Shandong, Shandong China

-

Brand Name:

-

Tiantai

-

Voltage:

-

3phase/380(customizable)

-

Power:

-

0-80KW(customizable)

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

3000 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

3BBL Beer Brewing Equipment

-

Application:

-

Restaurants, brewpub, brewery, bar, hotel

-

Function:

-

Beer Brewing

-

Material:

-

SUS304/SUS316/Copper

-

Keywords:

-

Two Vessel HLT Brewhouse

-

Capacity:

-

3BBL

-

Thickness:

-

Inner 3mm External 2mm

-

Heating way:

-

Steam Electric and direct fire

-

Control system:

-

Semi-automatic/Manual

Hey this is Sharon with sales manager from Tiantai Beer Equipment Co., Ltd., welcome to visit our brewery equipment pages and thanks very much for your interest in our product!

Please allow me to introduce this set of 3bbl brewery equipment to you by some descriptions and photos in below,

Any questions or other demands please feel free to contact us at anytime for more interested details:

For this 300l brewery equipment, almost 99% of our customers chose this 2 vessel brewhouse and heated by electric.

It mainly includes:

| Part 1: Malt Milling Unit | ||||

| 1.1 | Malt Miller [100-150kg/hr] | 1set | ||

| Part 2: 3BBL Brewhouse | ||||

| 2.1 | 4HL Mash/Lauter Tun | 1set | ||

| 2.2 | 4HL Kettle/Whirlpool Tun | 1set | ||

| 2.3 | 8HL Hot Water Tank | 1set | ||

| 2.4 | Non-slip Work Plateform | 1set | ||

| 2.5 | Sanitary Centrifugal Pump [LYSF] | 2sets | ||

| 2.6 | Sanitary Piping | 1set | ||

| 2.7 | Valves and Fittings | 1set | ||

| 2.8 | Manual Water Mixing Station | 0set | ||

| 2.9 | Manual Wort Cooling Station | 1set | ||

| 2.10 | Pipeline Instrument Sensor | 0unit | ||

| 2.11 | 25L Glass Wort Grant | 1set | ||

| 2.12 | 4M2 Heat Exchanger [304SS NANHUA] | 1set | ||

| 2.13 | Pipe Filter | 1set | ||

| 2.14 | Wort Aeration Station | 1set | ||

| 2.15 | 10L Yeast Feeder | 1set | ||

| Part 3: Fermentation Unit | ||||

| 3.1 | 400L Fermentation Tank/Unitank | 4sets | ||

| 3.3 | 400L Bright Beer Tank | 1set | ||

| Part 4: Glycol Cooling Unit | ||||

| 4.1 | 800L Glycol Water Tank | 1set | ||

| 4.2 | 5HP Glycol Water Chiller | 1set | ||

| 4.3 | Glycol Water Pipeline | 1unit | ||

| Part 5: Electric Control Unit | ||||

| 5.1 | Brewery Instrumental Control Cabinet | 1set | ||

| Part 6: Portable CIP Pump | ||||

| 6.1 | Portable CIP Pump | 1set | ||

More descriptions of the brewhouse:

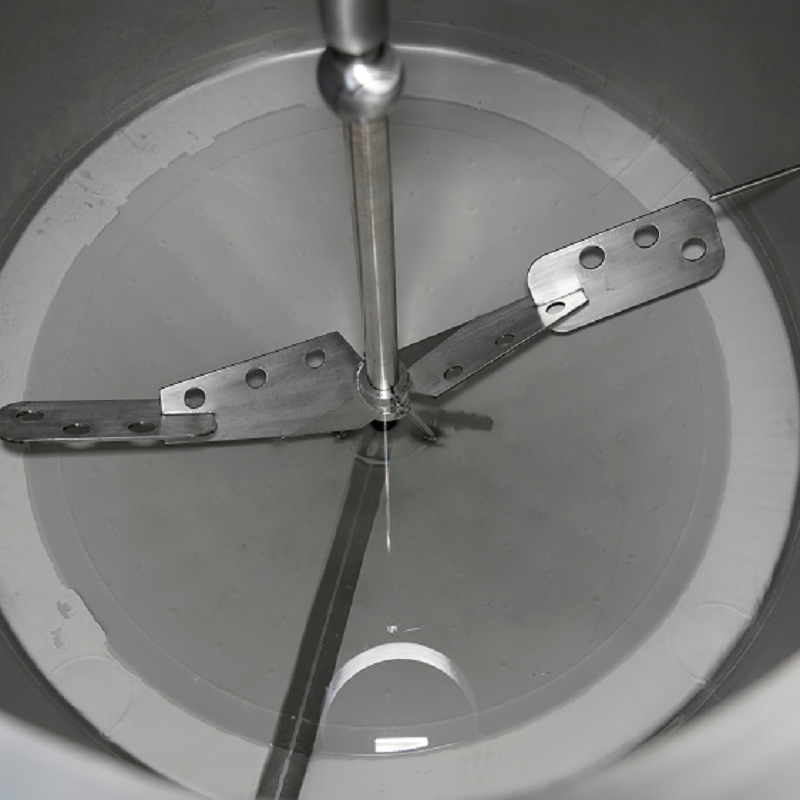

| 400L Mash/Lauter Tun x1set | |||

| ♦ | Function: Grain mashing, wort Lautering, sparging and whirpool | ||

| ♦ | Tank Capacity: 400L (+25% Headspace minimum) | ||

| ♦ | Dimension: Φ960x800mm (Width on base of 12plato OG) | ||

| ♦ | Interior Shell: SUS304 full welded; TH=3mm | ||

| ♦ | Exterior Shell:SUS304 full welded; TH=2mm | ||

| ♦ | 100% TIG welding with pure argon gas shield | ||

| ♦ | Interior Finish: Completely acid washing and passivation | ||

| ♦ | Inside polishing to 0.2~0.4 μm without dead corner | ||

| ♦ | Insulation: TH=80mm with environmental protection rock wool | ||

| ♦ | Heating: No (Steam, Direct fire for optional) | ||

| ♦ | Tank leakage test by full water for 72 hours | ||

| ♦ | Tank Working Pressure: Atmosphere | ||

| ♦ | Dished top full polished and conical bottom | ||

| ♦ | Top mounted SUS manhole | ||

| ♦ | Top mounted 360° rotary CIP spraying ball and port, 2pcs | ||

| ♦ | Sparging spray ring on top Easyclean and detachable | ||

| ♦ | Top mounted rotation motor ABB brand with VFD speed adjust | ||

| ♦ | High torque, low power consumption gear box | ||

| ♦ | Grain bed rake with positive inversion control | ||

| ♦ | Manually lifted spent grain dozer for spent grain out | ||

| ♦ | Side mounted enlarged spent grain manhole with glass with grain chute | ||

| ♦ | SUS304 wedge shape milling cut False Bottom/Filter plate with 0.7mm gap on top and 1.5mm bottom | ||

| ♦ | False bottom easy taken out from spent grain door | ||

| ♦ | Easy clean support at bottom for False bottom/Filter plate | ||

| ♦ | Sanitary welded thermowell for high accuracy temperature sensor | ||

| ♦ | CIP inlet on top | ||

| ♦ | Sparging water inlet on top | ||

| ♦ | Wort circulation inlet on top with wort check sight glass | ||

| ♦ | Wort outlet in center of the bottom | ||

| ♦ | 4pcs completely SUS304 legs with braces | ||

| ♦ | 4 sets heavy duty foot pad with up-down and slop adjustable | ||

| 400L Kettle/Whirlpool Tun | |||

| ♦ | Function: Wort boiling and hopping | ||

| ♦ | Tank Capacity:400L (+30% Headspace minimum) | ||

| ♦ | Dimension: Φ960x800mm | ||

| ♦ | Interior Shell: SUS304 full welded; TH=3mm | ||

| ♦ | Exterior Shell:SUS304 full welded; TH=2mm | ||

| ♦ | 100% TIG welding with pure argon gas shield | ||

| ♦ | Interior Finish: Completely acid washing and passivation | ||

| ♦ | Inside polishing to 0.2~0.4 μm without dead corner | ||

| ♦ | Insulation: TH=80mm with environmental protection rock wool | ||

| ♦ | Heating: Electric (Steam, Direct fire for optional) | ||

| ♦ | Tank leakage test by full water for 72 hours | ||

| ♦ | Tank Working Pressure: Atmosphere | ||

| ♦ | Dished top full polished | ||

| ♦ | Conical bottom | ||

| ♦ | Top mounted SUS manhole | ||

| ♦ | Top mounted 360° rotary CIP spraying ball and port, 1pc | ||

| ♦ | Sanitary liquid level indicator with valves | ||

| ♦ | Steam condensor with spray nozzle and valves | ||

| ♦ | Sanitary welded thermowell for high accuracy temperature sensor | ||

| ♦ | Wort inlet on top with elbow to side wall | ||

| ♦ | CIP inlet on top | ||

| ♦ | Tangential whirlpool inlet with reducing port | ||

| ♦ | Wort outlet on slope of the bottom | ||

| ♦ | Discharging port at center of the bottom | ||

| ♦ | Trub dam at bottom full welded | ||

| ♦ | 4pcs completely SUS304 legs with braces | ||

| ♦ | 4 sets heavy duty foot pad with up-down and slop adjustable | ||

Fermentation tanks:

Brewery cases: