- Product Details

- {{item.text}}

Quick Details

-

Material:

-

natural rubber and steel wire incorporated

-

Quality:

-

unquestionably equivalent to that of OEM brands

-

Application:

-

mini excavators, midi excavators

-

MOQ:

-

2pcs

-

Certification:

-

ISO9001;ROHS;REACH

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

GQRT

-

Width:

-

13 cm (130 mm) to 100 cm (1,000mm)

-

Material:

-

natural rubber and steel wire incorporated

-

Quality:

-

unquestionably equivalent to that of OEM brands

-

Application:

-

mini excavators, midi excavators

-

MOQ:

-

2pcs

-

Certification:

-

ISO9001;ROHS;REACH

Product Overview

RUBBER TRACKS FOR EXCAVATORS, MINI DIGGERS & MORE MACHINERY PARTS

Kaixu International supplies rubber tracks in the range from 13 cm (130 mm) to 100 cm (1,000 mm) wide. This extensive range of rubber tracks is available for all types of earth-moving machines such as: mini excavators, midi excavators, crawler-mounted dumpers, skid-steers and track loaders.

Kaixu International rubber track quality is unquestionably equivalent to that of OEM brands.

All Kaixu Track rubber excavator tracks have steel wire incorporated. Moreover, our enormous stock enables us to supply any rubber crawler track quickly.

Products Description

Rubber Track Weight

While many competitors use recycled rubber, Kaixu International uses a special compound of pure natural rubber. Tracks with recycled rubber are heavier, but certainly not stronger – so weight is not all-important.

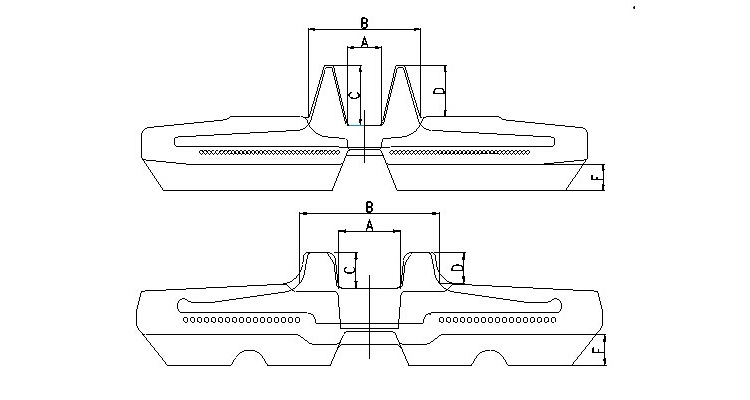

RUBBER TRACK DIMENSIONS

Machine builders define which tracks run best under their undercarriage. They make the choice between long pitch rubber tracks and

short pitch rubber tracks, depending on the choice of bottom rollers, final drive and sprocket width.

short pitch rubber tracks, depending on the choice of bottom rollers, final drive and sprocket width.

* Long pitch rubber tracks, have few lugs. They have a larger pitch size than short pitch tracks. The lugs run on every other sprocket tooth.

* Short pitch rubber tracks, have double the number of lugs. They have a smaller pitch size than long pitch tracks. The lugs run in each sprocket tooth, so that the machine runs with less vibration. With short pitch tracks, the chance of packing (soil accumulation between the lugs) is greater than with long pitch tracks. Note that although short pitch tracks offer more comfort for the operator than long pitch tracks, short pitch tracks are not the same as Anti Vibrate Tracks (AVT).

* Short pitch rubber tracks, have double the number of lugs. They have a smaller pitch size than long pitch tracks. The lugs run in each sprocket tooth, so that the machine runs with less vibration. With short pitch tracks, the chance of packing (soil accumulation between the lugs) is greater than with long pitch tracks. Note that although short pitch tracks offer more comfort for the operator than long pitch tracks, short pitch tracks are not the same as Anti Vibrate Tracks (AVT).

AVT RUBBER TRACKS

AVT stands for Anti Vibrate Tracks. The advantages of AVT tracks include: less vibration, less wear and more comfort for the

operator. AVT tracks are often chosen when working a lot on hard flat surfaces. Regular rubber digger tracks are recommended when

working on loamy and soft surfaces. A disadvantage of AVT rubber digger tracks is namely that debris and soil can accumulate

between the lugs (packing).

operator. AVT tracks are often chosen when working a lot on hard flat surfaces. Regular rubber digger tracks are recommended when

working on loamy and soft surfaces. A disadvantage of AVT rubber digger tracks is namely that debris and soil can accumulate

between the lugs (packing).

HOW CAN YOU RECOGNISE THE WEAR PATTERNS OF RUBBER EXCAVATOR TRACKS?

Some common wear patterns on excavator tracks from practice are:

* When the lug has visible damage, then there is a big chance that the sprocket tooth has come into contact with the lug.

* The cutting blade (or cutting edge) has cut into the track; you can recognise this by a cut in the rubber track.

* Lugs that have rusted away; this can occur when working in sea areas, acid soils, alkaline-containing raw materials, or

compost. In these cases, it is even more important to clean the undercarriage regularly.

* Cracks on the outside without any damage on the inside. This is caused by sharp materials infiltrating from the outside. If there is no damage to the steel cables inside the tracks, you can keep on using the machine as usual.

* UV light makes the rubber become porous, which may cause cracks.

* External rubber wear can also be caused by frequent tilting. You can keep on using the tracks as long as no steel cables are visible.

* When the lug has visible damage, then there is a big chance that the sprocket tooth has come into contact with the lug.

* The cutting blade (or cutting edge) has cut into the track; you can recognise this by a cut in the rubber track.

* Lugs that have rusted away; this can occur when working in sea areas, acid soils, alkaline-containing raw materials, or

compost. In these cases, it is even more important to clean the undercarriage regularly.

* Cracks on the outside without any damage on the inside. This is caused by sharp materials infiltrating from the outside. If there is no damage to the steel cables inside the tracks, you can keep on using the machine as usual.

* UV light makes the rubber become porous, which may cause cracks.

* External rubber wear can also be caused by frequent tilting. You can keep on using the tracks as long as no steel cables are visible.

Product Paramenters

|

Width*Pitch(mm)

|

Links

|

A

|

B

|

C

|

D

|

F

|

|

130X72

|

29-40

|

23

|

64.5

|

28

|

28

|

15

|

|

150X60

|

32-40

|

22

|

64

|

22.5

|

24.5

|

15

|

|

150X72

|

29-40

|

23

|

64

|

23

|

23

|

15

|

|

170X60

|

30-40

|

19

|

57

|

22

|

22

|

13

|

|

180X60

|

30-40

|

23.5

|

64

|

21

|

21.5

|

15

|

|

180X72

|

31-43

|

25

|

68

|

29

|

29

|

15

|

|

180X72K

|

32-48

|

20

|

61

|

22

|

19.5

|

17

|

|

180X72KM

|

30-46

|

23

|

64

|

29

|

31

|

15

|

|

180X72YM

|

30-46

|

22.5

|

65

|

29

|

29

|

14

|

|

V180X72K

|

30-50

|

20

|

61

|

22

|

19.5

|

17

|

|

190X60

|

30-40

|

23.5

|

64

|

21

|

21.5

|

14

|

|

190X72

|

31-41

|

21

|

68

|

27.5

|

26.5

|

15

|

|

200X72

|

34-47

|

23

|

76

|

28.5

|

26.5

|

18

|

|

200X72K

|

37-47

|

21

|

69

|

29.5

|

29

|

18

|

|

Y200X72

|

40-52

|

24

|

64

|

28.5

|

29.5

|

12

|

|

230X48

|

60-84

|

24

|

72

|

24

|

25

|

21

|

|

230X48A

|

60-84

|

26

|

69

|

22

|

24

|

17

|

|

230X48K

|

60-84

|

24

|

66

|

21

|

20

|

19

|

|

230X72

|

42-56

|

24

|

82

|

30

|

26

|

18

|

|

230X72K

|

42-56

|

20

|

69

|

29.5

|

28

|

16

|

|

V230X72K

|

42-56

|

20

|

69

|

29.5

|

28

|

16

|

|

230X96

|

30-48

|

25

|

68

|

23.5

|

25.5

|

22

|

|

230X101

|

30-36

|

25

|

74

|

22.5

|

29

|

19

|

|

250X47K

|

84

|

23

|

70

|

24

|

20

|

22

|

|

250X48.5K

|

80-88

|

24

|

66

|

21

|

20

|

19

|

|

250X52.5

|

72-78

|

29

|

72

|

23

|

25

|

21

|

|

250X52.5N

|

72-78

|

30

|

82

|

25

|

18

|

20

|

|

250X52.5K

|

72-78

|

26

|

81

|

23

|

25

|

25

|

|

250X96

|

35-38

|

25

|

70

|

20

|

19

|

22

|

|

250X109

|

35-38

|

40

|

89

|

24.5

|

14

|

20

|

|

260X52.5

|

74-80

|

40

|

88

|

23

|

22

|

23

|

|

260X55.5K

|

74-80

|

31

|

80

|

21.5

|

27

|

24

|

|

280X72

|

45-64

|

25

|

78

|

29.5

|

26

|

22

|

|

Y280X106K

|

35-42

|

30

|

80

|

27.5

|

28

|

20

|

|

300X52.5N

|

72-98

|

30

|

82

|

25

|

18

|

20

|

|

300X52.5W

|

72-92

|

43

|

96

|

22

|

23

|

22

|

|

300X52.5K

|

70-88

|

29

|

84

|

27

|

26

|

22

|

|

300X52.5KW

|

72-92

|

40

|

92

|

25

|

24

|

22

|

|

300X53K

|

80-96

|

31

|

88

|

25

|

19.5

|

21

|

|

300X109N

|

35-42

|

29

|

82

|

27

|

28

|

25

|

|

300X109W

|

35-44

|

38

|

90

|

26

|

29

|

24

|

|

320X52.5

|

72-98

|

30

|

83

|

23.5

|

18

|

21

|

|

Y320X106K

|

39-43

|

31

|

80

|

26

|

27

|

24

|

|

350X52.5

|

70-92

|

40

|

94

|

22.5

|

19

|

30.5

|

|

350X54.5K

|

80-86

|

40

|

92

|

23.5

|

22.5

|

23

|

|

400X72.5N

|

70-80

|

38

|

100

|

26

|

24

|

25

|

|

400X72.5W

|

68-76

|

51

|

108

|

26

|

24

|

25

|

|

........

|

|

|

|

|

|

|

Hot Searches