- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

300 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

Customized

-

Power:

-

84

-

Raw Material:

-

Fresh tomato

-

End Products:

-

Tomato sauce

-

Processing Capacity:

-

10-1500T Fresh Fruit/day

-

Sterilization Method 1:

-

Pasteurization

-

Sterilization Method 2:

-

UHT high temperature sterilization

-

Terminal Packaging Option 1:

-

Aseptic vat

-

Terminal Packaging Option 2:

-

bag-in-box aseptic pouch

-

Terminal Packaging Option 3:

-

tinplate small packaging

-

Terminal Packaging Option 4:

-

pouch packaging

Quick Details

-

Machinery Capacity:

-

500kg/h-50 tons/h

-

Brand Name:

-

NC, NC

-

Year:

-

2022

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

300 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

Customized

-

Power:

-

84

-

Raw Material:

-

Fresh tomato

-

End Products:

-

Tomato sauce

-

Processing Capacity:

-

10-1500T Fresh Fruit/day

-

Sterilization Method 1:

-

Pasteurization

-

Sterilization Method 2:

-

UHT high temperature sterilization

-

Terminal Packaging Option 1:

-

Aseptic vat

-

Terminal Packaging Option 2:

-

bag-in-box aseptic pouch

-

Terminal Packaging Option 3:

-

tinplate small packaging

-

Terminal Packaging Option 4:

-

pouch packaging

Product Overview

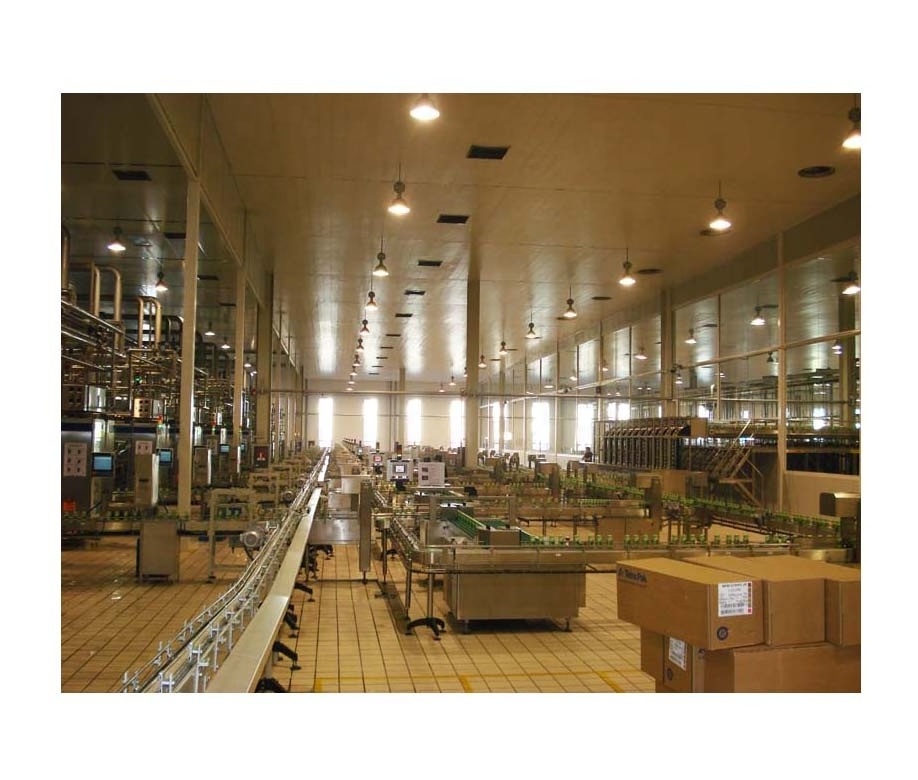

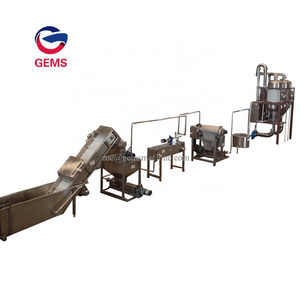

Tomato RELISH Processing Plant Tomato Purée Making Machinery

Tomatoes are generally processed into tomato paste or tomato juice. The tomato paste production line mainly includes five parts: fresh tomato receiving, cleaning and sorting system; crushing and pulping system; concentration system; sterilization system; aseptic filling system. Fresh tomatoes are cleaned, upgraded, sorted, crushed and beaten, concentrated and sterilized, and then aseptically filled to become the finished tomato sauce in barrels. The entire production line and related equipment are specially designed for tomato sauce in accordance with the principles of international high-quality standards.

PRODUCT SPECIFICATIONS

|

Raw Material

|

Fresh tomato

|

|

End Products

|

Tomato sauce (concentration is 28-30%, 30-32%, 36-38%)

|

|

Processing Capacity

|

10-1500T Fresh fruit/day

|

|

Ingredients of the Jam

|

Various flavor additives such as pure fruit puree, vitamins, sugar, etc.

|

|

Sterilization Method

|

Pasteurization, UHT high temperature sterilization, (adjustable based on specific requirements)

|

|

Terminal Packaging

|

Aseptic vat, bag-in-box aseptic pouch, tinplate small packaging, pouch packaging

|

|

Control Method

|

Less than 300 tons: Manual control or automatic control

|

|

System Composition

|

Original fruit lifting system, cleaning system, sorting system, crushing system, preheating enzyme inactivation system, beating

system, vacuum concentration system, blending system, sterilization system, aseptic big bag filling system, small package filling system |

END PRODUCT

KETCHUP

TOMATO PASTE

TOMATO PUREE

TOMATO SAUCE

PACKAGE TYPE

Hot Searches