- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ALLRAISE

-

Dimension(L*W*H):

-

9000 * 2100 *2200 mm

-

Weight:

-

7000 KG, 7000 Kg

-

Model:

-

ORJW-1210

-

Max.Paper Size:

-

1200 * 1000 mm

-

Min.Paper Size:

-

450 *300 mm

-

Thickness of upper paper:

-

100-800 g/m²

-

Thickness of bottom paper:

-

180-2400 g/m²

-

Dimension:

-

9000 * 2100 *2200 mm

-

Power:

-

12kw

Quick Details

-

Packaging Type:

-

Cartons, CANS, Bags, Film

-

Packaging Material:

-

Plastic, Paper

-

Driven Type:

-

Electric

-

Voltage:

-

220V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ALLRAISE

-

Dimension(L*W*H):

-

9000 * 2100 *2200 mm

-

Weight:

-

7000 KG, 7000 Kg

-

Model:

-

ORJW-1210

-

Max.Paper Size:

-

1200 * 1000 mm

-

Min.Paper Size:

-

450 *300 mm

-

Thickness of upper paper:

-

100-800 g/m²

-

Thickness of bottom paper:

-

180-2400 g/m²

-

Dimension:

-

9000 * 2100 *2200 mm

-

Power:

-

12kw

Products Description

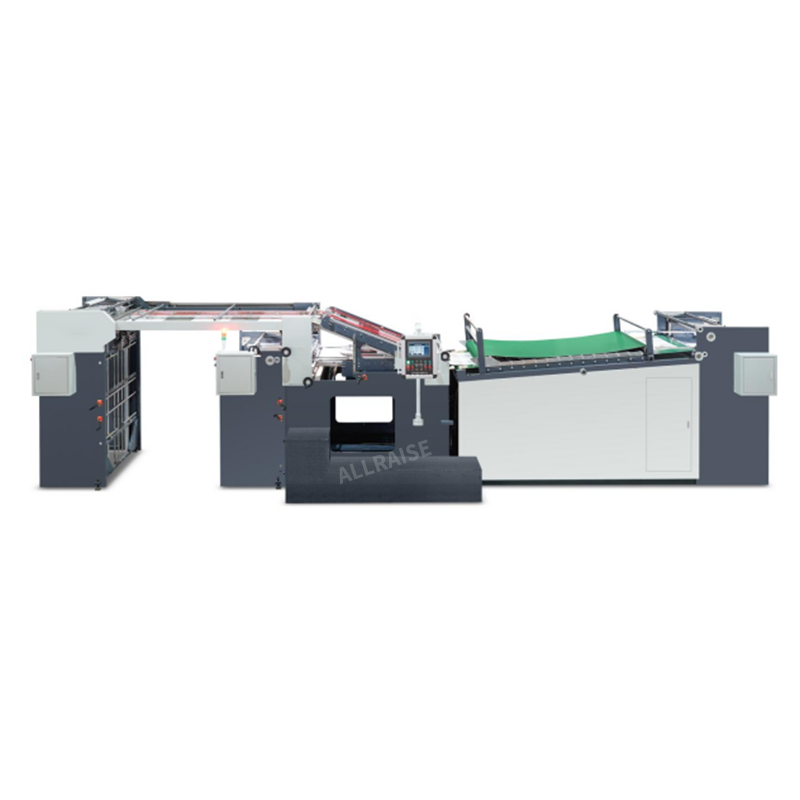

Fully automatic film cardboard pvc glue coating lamination machine plastic laminating machines

|

Product Name

|

Automatic coating laminating machine

|

|

Model

|

ORJW-1210

|

|

Max Paper Size

|

1200 * 1000 mm

|

|

Min Paper Size

|

450 * 300 mm

|

|

Thickness of upper paper

|

100-800 g/m²

|

|

Thickness of bottom paper

|

180-2400 g/m²

|

|

Max.Speed

|

105 pcs/min

|

|

Accuracy

|

±0.5 mm

|

|

Power

|

12 Kw

|

|

Weight

|

7000 Kg

|

|

Operating Space

|

3000*12000 mm

|

|

Overall Dimension(LxWxH)

|

9000 * 2100 * 2200 mm

|

|

1

|

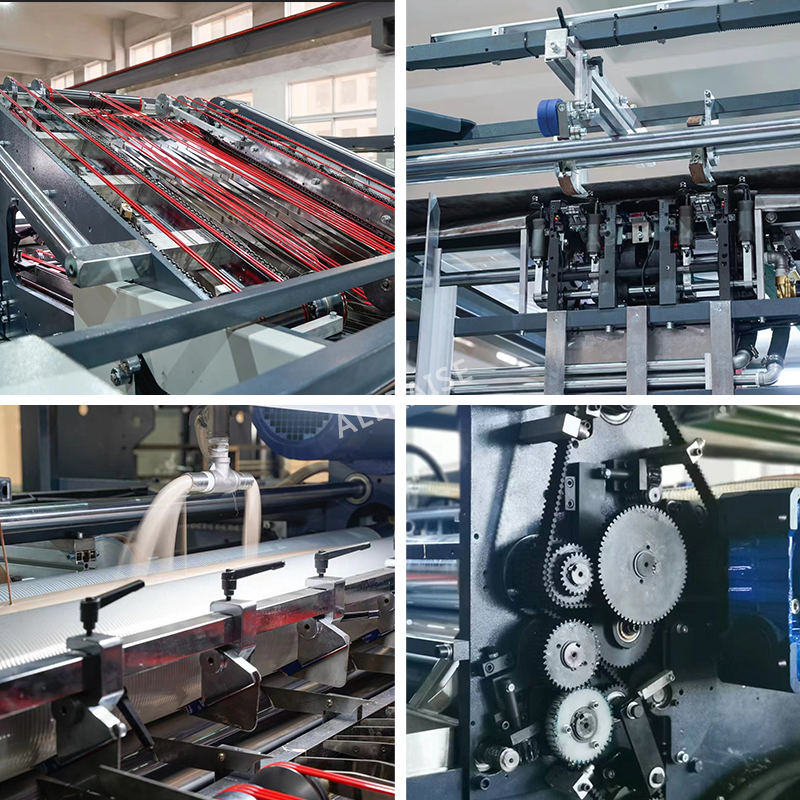

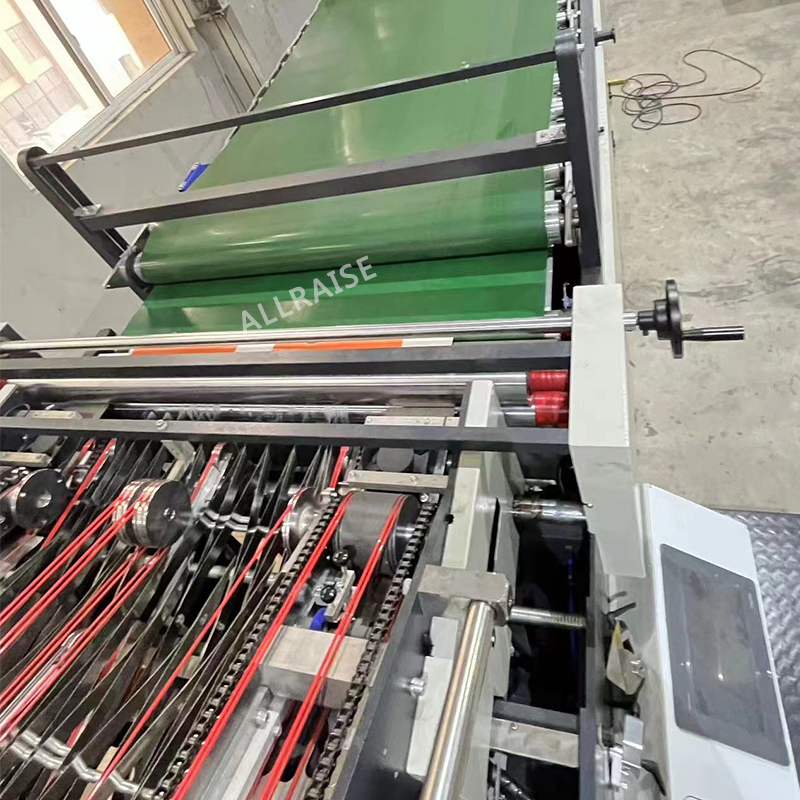

Unique paper dynamic aligning system, the whole machine in power transmission by a complete set of timer belts. Free maintenance, low noise and high efficiency.

|

|

2

|

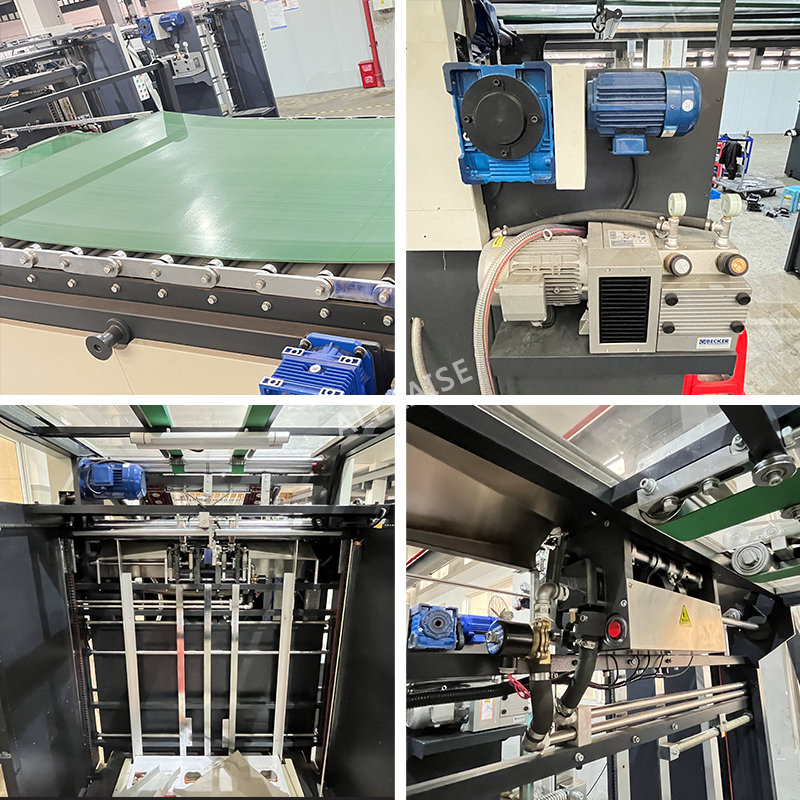

Leading-edge feeder system, easy to operate for different jobs.

|

|

3

|

Vibra-Loose Collecting Mechanism, capable of loosening mullet-laid laminated sheets and pushing neatly to ensure smooth collection of paper. E-type holder plate and high-speed elevator jointly pull-out laminated sheets rapidly and conveniently, which greatly increase the working efficiency.

|

|

4

|

Adopt E-type paper holder plate, convenient for quick paper replenishment by pushing pallet trolley directly to the holder plate.

|

|

5

|

Motorized calibration of running speed and pressing paper Length allows easy change-over of different paper sizes.

|

|

6

|

Under control of high precision coating mechanism, the coating volume of gluing roller and glue adjusting roller can reach less than 0.08mm. Automatic glue level control: accurately adjust coating volume required by different paper to ensure even gluing.

|

|

7

|

Convenient paper separator: separate the paper from the gluing roller quickly and easy for dismantling, cleaning and calibration of the gluing roller, wipe the glue back to the roller to prevent roller ends at high speed from glue overflowing, and it can also adjust back flow to recycle the glue.

|

|

8

|

Use PLC computer program control system, monitor display for machine running in real time.

|

Related Products

Tel/Whats App/Wechat: +86 15378755823

Package&Shipping

|

Packaging

|

By container or standard export packing per machine

|

|

Delivery time

|

15-30 days after payment received

|

Hot Searches