- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1-0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

TT-OS

-

Brand Name:

-

TONTEN

-

Product name:

-

Olivine sand

-

Form:

-

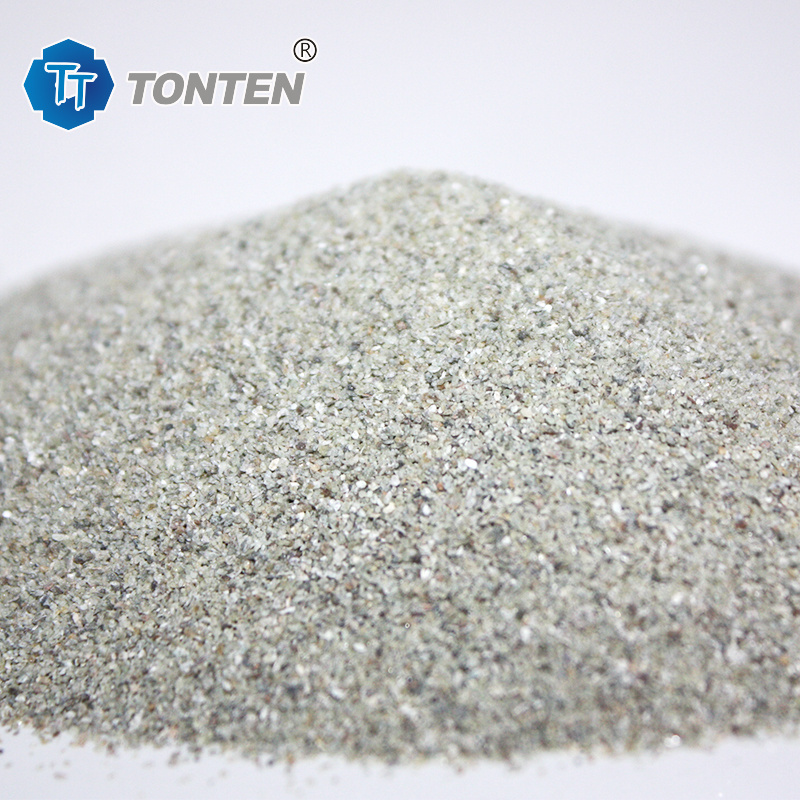

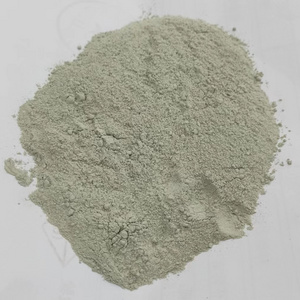

powder or sand, particles

-

Color:

-

Grayish

-

Bulk Density(g/cm3):

-

3.2-3.4

-

Melting points:

-

1600 deg. Centg.

-

Application:

-

Casting material

-

Usage:

-

refractory, foundry, etc.

-

Package:

-

25kg/bag

-

Sample:

-

Provide

Quick Details

-

SiO2 Content (%):

-

50%~65%

-

Al2O3 Content (%):

-

38-48%

-

MgO Content (%):

-

0.8-1.2

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1-0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

TT-OS

-

Brand Name:

-

TONTEN

-

Product name:

-

Olivine sand

-

Form:

-

powder or sand, particles

-

Color:

-

Grayish

-

Bulk Density(g/cm3):

-

3.2-3.4

-

Melting points:

-

1600 deg. Centg.

-

Application:

-

Casting material

-

Usage:

-

refractory, foundry, etc.

-

Package:

-

25kg/bag

-

Sample:

-

Provide

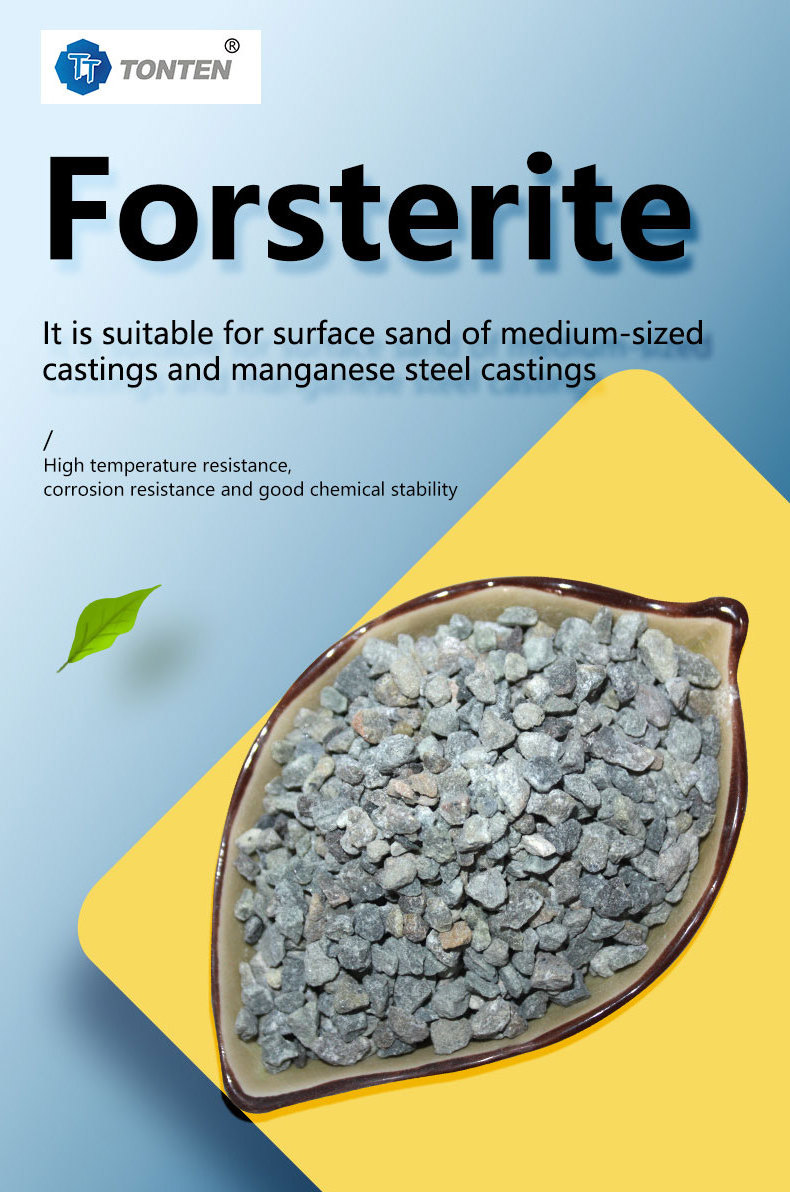

Olivine sand is an artificial sand made of pure peridotite through mechanical processing and sorting.

Molding sand for casting models and steel castings of brass, bronze, aluminum and magnesium.

Generally requires MgO>45%, SiO2<40%, Al2O3<3%, FeO<11%, and the particle size ranges from 36 to 200 mesh

|

Good thermal conductivity Good thermal conductivity, slow and uniform thermal expansion, not easy to produce sand inclusion. |

|

|

Good production environment No free SiO exists, no silica sand hazard, no CO gas is generated during casting, and the production environment is good. |

|

|

High fire resistance High fire resistance, strong resistance to metal oxide corrosion, can effectively prevent chemical and mechanical sand sticking of castings, good surface quality of castings, accurate size and high qualification rate. |

|

|

High recovery Due to the high melting point and stable chemical properties of magnesium olive sand, it has strong etching ability for iron oxides and alkaline slag, is easy to recover, and can reduce the production cost. |

Applications:

1. Forsterite sand is suitable for the modeling of special ordinary castings, especially the ideal modeling material for high manganese steel parts.

2. Forsterite powder can also be used as a chemical raw material and is the base material of phosphate-magnesium fertilizer.

3. Forsterite refractories are widely used in the lining of alkaline steelmaking and non-ferrous metal smelting furnaces.

Advantages:

1. Good thermal conductivity, slow and uniform thermal expansion, not easy to produce sand.

2. There is no free SiO, no silica snd hazard, no CO gas generated during casting, and a good production environment.

3. High refractoriness, string resistance to metal oxide corrosion, can effectively prevent chemical and mechanical sand sticking of castings, good casting surface quality, accurate dimensions, and high qualification rate.

4. The recovery rate is high. Due to the high melting point of the forsterite sand, the stable chemical properties, the corrosion resistance to iron oxides and alkaline slag, the easy recovery, and the reduction of production costs.

Packing details: 25kg(55lb)/bag, 40 bags packed in a 1000kg (2200lb) bulk bag or pallet

1000kg(2200lb)/jumbo bag or as requirement

Delivery details: 3-25 days after payment according to your order quantities

1.You are a manufacture or a trading company?

We are truly a manufacture, we not only can provide the high quality products with the best price, but also can offer the best pre-sale service and after-service.

2. How can we guarantee quality?

Always a pre-production sample before mass production:

Always final inspection before shipmemt.

3. Why should you buy from us not from other suppliers?

We have more than 10 years experience in the machine, we can supply high quality machine according to customer request. In addition, we have good after service.

4. What services can we provide?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currency:USD, EUR, CNY;

Accepted payment type: T/T, L/C, D/P, etc.