- Product Details

- {{item.text}}

Quick Details

-

Engine Brand:

-

Imported

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Tewrex

-

Dimension(L*W*H):

-

5060*2466*3464mm

-

Exciting Force:

-

103/159KN

-

Service mass:

-

15000kg

-

Theoretical gradeability:

-

20%

-

Minimum turning radius:

-

7620mm

-

Minimum ground clearance:

-

300mm

-

Compaction width:

-

2360mm

-

Wheelbase:

-

3840mm

-

Engine model:

-

SC7H180.2G3

-

Rated power:

-

132kw

-

Diesel tank volume:

-

170L

Quick Details

-

Type:

-

Vibratory Roller

-

Power:

-

132 KW

-

Weight:

-

15 TON

-

Engine Brand:

-

Imported

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Tewrex

-

Dimension(L*W*H):

-

5060*2466*3464mm

-

Exciting Force:

-

103/159KN

-

Service mass:

-

15000kg

-

Theoretical gradeability:

-

20%

-

Minimum turning radius:

-

7620mm

-

Minimum ground clearance:

-

300mm

-

Compaction width:

-

2360mm

-

Wheelbase:

-

3840mm

-

Engine model:

-

SC7H180.2G3

-

Rated power:

-

132kw

-

Diesel tank volume:

-

170L

Product Description

The XP303 tire roller is a large-tonnage tire roller produced according to market requirements. It uses pneumatic tires as a

working device to compact the laminate material, mainly for asphalt pavement, foundation layer, sub-base layer, dam and fill.

Compaction operations such as engineering are ideal compaction equipment for the construction of high-grade roads, airports,

ports, dams and industrial construction sites.

Performance characteristics

1. Adopting Shangchai SC7H180.2G3 electronically controlled diesel engine with high reliability and fuel economy, low noise and

low emission to meet the national III standard.

2. Adopting hydraulic torque converter with stepless automatic shifting and power shifting gearbox, the roller has automatic

adaptability. When the external load suddenly increases, the roller can automatically decelerate and increase.

Gravity; when the external load is reduced, the traction force can be automatically reduced to adapt to the change of the external

load, and the compactness of the transmission can be improved to ensure that the diesel engine often works under rated conditions.

3. When the roller is turning or each driving wheel has different driving conditions and different ground adhesion factors, it can

prevent the wheel from slipping and slipping.

4. The parking brake is pneumatically controlled.

5. The volume of the gas storage cylinder is doubled, the reserve coefficient is larger, and it is safe and reliable, especially

suitable for frequent braking conditions in mountainous areas.

6. The exclusive use of dual-circuit braking system in China has higher braking efficiency, faster reaction speed, shorter braking

distance and higher reliability.

7. Adopt all-wheel braking technology to ensure the safety of the whole machine, especially for mountain working conditions.

8. The fuselage adopts a box-type integral frame. The front and middle sides and the lower part of the frame are counterweight

water tanks, which can also be used as water for watering.

Each part of the fuselage is designed with a service hole and a flip cover to facilitate the maintenance and maintenance of

various components.

9. The intelligent intermittent sprinkler system can not only greatly improve the reliability of the sprinkler system, but also

minimize the impact of sprinkler operations on the quality of the pavement.

10. Optional intermittent oil spill system can meet the needs of domestic users, save manpower and material resources, and

effectively reduce the adhesion of tire tread asphalt and improve work quality.

11. Optional centralized inflation.

working device to compact the laminate material, mainly for asphalt pavement, foundation layer, sub-base layer, dam and fill.

Compaction operations such as engineering are ideal compaction equipment for the construction of high-grade roads, airports,

ports, dams and industrial construction sites.

Performance characteristics

1. Adopting Shangchai SC7H180.2G3 electronically controlled diesel engine with high reliability and fuel economy, low noise and

low emission to meet the national III standard.

2. Adopting hydraulic torque converter with stepless automatic shifting and power shifting gearbox, the roller has automatic

adaptability. When the external load suddenly increases, the roller can automatically decelerate and increase.

Gravity; when the external load is reduced, the traction force can be automatically reduced to adapt to the change of the external

load, and the compactness of the transmission can be improved to ensure that the diesel engine often works under rated conditions.

3. When the roller is turning or each driving wheel has different driving conditions and different ground adhesion factors, it can

prevent the wheel from slipping and slipping.

4. The parking brake is pneumatically controlled.

5. The volume of the gas storage cylinder is doubled, the reserve coefficient is larger, and it is safe and reliable, especially

suitable for frequent braking conditions in mountainous areas.

6. The exclusive use of dual-circuit braking system in China has higher braking efficiency, faster reaction speed, shorter braking

distance and higher reliability.

7. Adopt all-wheel braking technology to ensure the safety of the whole machine, especially for mountain working conditions.

8. The fuselage adopts a box-type integral frame. The front and middle sides and the lower part of the frame are counterweight

water tanks, which can also be used as water for watering.

Each part of the fuselage is designed with a service hole and a flip cover to facilitate the maintenance and maintenance of

various components.

9. The intelligent intermittent sprinkler system can not only greatly improve the reliability of the sprinkler system, but also

minimize the impact of sprinkler operations on the quality of the pavement.

10. Optional intermittent oil spill system can meet the needs of domestic users, save manpower and material resources, and

effectively reduce the adhesion of tire tread asphalt and improve work quality.

11. Optional centralized inflation.

Contact us: Monica Yin

Whatsapp/Wechat/Mobile:008618862629277

Email: monica@tewrex.com

Email: monica@tewrex.com

|

Item

|

Unit

|

XP303

|

|

Minimum operating mass

|

kg

|

15000

|

|

Maximum operating mass

|

kg

|

30300

|

|

Mass of added heavy water

|

kg

|

650

|

|

Added mass

|

kg

|

14550

|

|

Compacting width

|

mm

|

2360

|

|

Overlap amount of tires

|

mm

|

65

|

|

Ground pressure

|

kPa

|

200~545

|

|

Minimum turning radius

|

mm

|

7620

|

|

Swing amount of front wheel

|

mm

|

±50

|

|

Minimum ground clearance

|

mm

|

300

|

|

Theoretical gradeability

|

%

|

20

|

|

Wheelbase

|

mm

|

3840

|

|

Running speed

|

km/h

|

0~8

|

|

Speed I

|

km/h

|

0~17

|

|

Speed II

|

|

|

|

Model of diesel engine

|

|

SC7H180.2G3

|

|

Rated power

|

kW

|

132

|

|

Rated speed

|

r/min

|

1800

|

|

Rated fuel oil consumption

|

g/kW·h

|

≤233

|

|

Tire specification

|

|

13/80-20

|

|

Tread pattern

|

|

Smooth tread tire

|

|

Number of tires

|

|

4 front tires and 5 rear tires

|

|

Length (standard for sprinkling water)

|

mm

|

4925

|

|

Length (optional for spraying oil)

|

mm

|

5015

|

|

Width

|

mm

|

2530

|

|

Height

|

mm

|

3370

|

|

Capacity of fuel tank L

|

L

|

170

|

|

Capacity of water tank L

|

L

|

650

|

Details Images

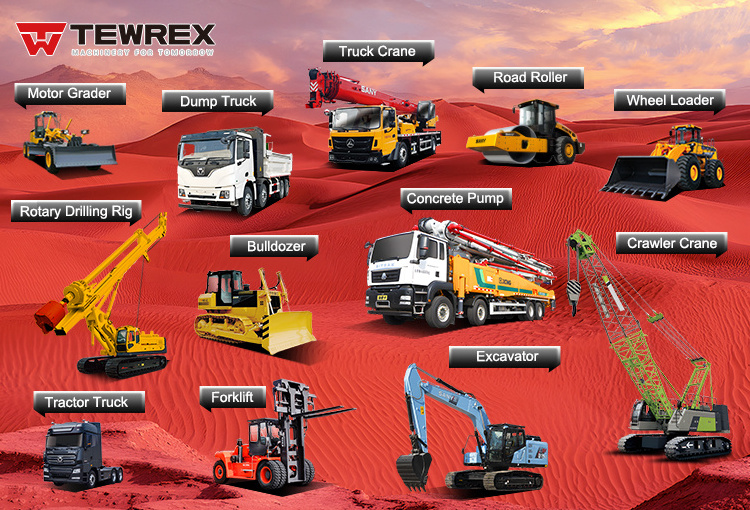

Recommend Products

Hot Searches