- Product Details

- {{item.text}}

Quick Details

-

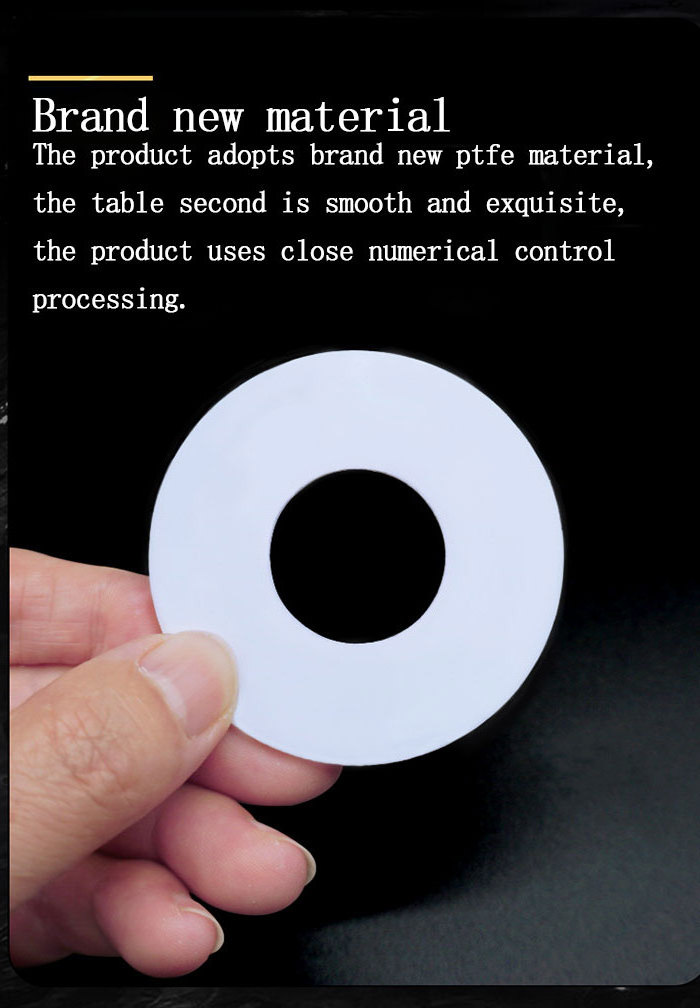

Product name:

-

PTFE Gasket

-

Shape:

-

O-Ring or customized

-

Purity:

-

100% Virgin PTFE Micro Powder

-

Size:

-

Can be custom

-

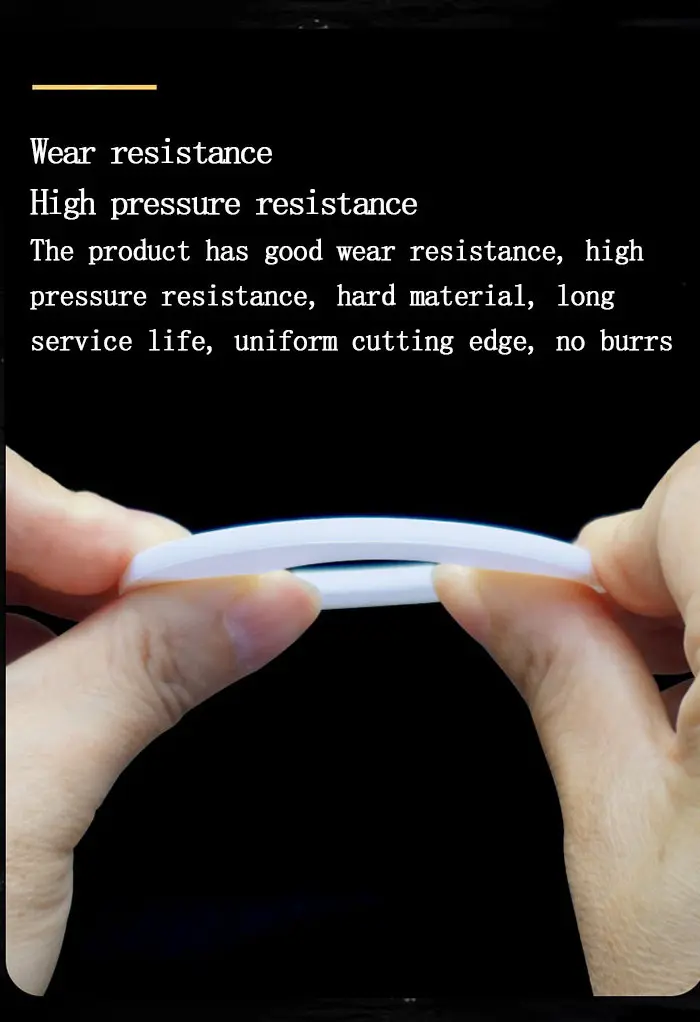

Wear resistance:

-

High lubrication

-

Working temperature:

-

-100℃~100℃

-

Color:

-

White

-

Feature:

-

Good Electrical insulation,high temperature resist,

-

Performance:

-

Resistance to oxidation

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Mengfei

-

Model Number:

-

Customized

-

Product name:

-

PTFE Gasket

-

Shape:

-

O-Ring or customized

-

Purity:

-

100% Virgin PTFE Micro Powder

-

Size:

-

Can be custom

-

Wear resistance:

-

High lubrication

-

Working temperature:

-

-100℃~100℃

-

Color:

-

White

-

Feature:

-

Good Electrical insulation,high temperature resist,

-

Performance:

-

Resistance to oxidation

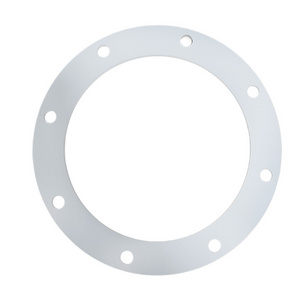

Specification

|

Product Name

|

PTFE Gasket and PTFE Products

|

|

Shape

|

Ring or other

|

|

Size

|

Can be custom

|

|

Color

|

White

|

Product description:

Rigor

In fluid machinery (such as pumps, compressors, mixing kettles, centrifuges, etc.), the parts with the most severe operating conditions are PTFE gaskets.

(1) Accept axial force like a thrust bearing;

(2) Export the generated heat like a radiator;

(3) In the case of high temperature and high pressure and easy corrosion, static sealing is very difficult, and it is even more difficult to complete dynamic sealing on a sealing surface of several millimeters in high-speed rotation.

Working environment

(1) Without an auxiliary system, it is only possible to improve the sealing structure and improve the raw materials. (It's expensive and doesn't fundamentally solve the problem.)

(2) In practice, there are almost no PTFE gaskets without any auxiliary equipment. For example, tandem PTFE gaskets and high temperature PTFE gaskets used in high pressure must use corresponding auxiliary equipment.

(3) (Through the auxiliary system) severe working conditions have become acceptable working conditions for sealing (the effect of tetrafluoro gaskets has been greatly improved, the scope of application has become more extensive, the demand for sealing materials is reduced, and the cost of tetrafluoro gaskets is reduced.).

Manipulate

Excessive frictional heat on the end face has the following damages: (1) Vaporization and wear of the liquid film aggravate the seal failure; (2) Thermal deformation of the end face increases leakage and wear; (3) Increases corrosion; (4) Assists the aging and deterioration of the sealing ring and then fails; ( 5) Stone

The ink impregnated material carbonized or melted and leaked. Therefore, the temperature rise of the end face is the enemy of the PTFE gasket. ).

Product Description

Product Features

Hot Searches