- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Brand Name:

-

silian

-

Applicable Industries:

-

Cosmetic, Chemical

-

Weight (KG):

-

500

Product Overview

Semi automatic filling and sealing machine

* Manually tube feeding, automatic registration mark identifying, filling, sealing with coding, end trimming, tube out feeding.

*Cam indexing system could position precisely for ten working stations.

*Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

* Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adju st the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

* PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen, could locate the problem and solve immediately.

* Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

* No tube, no fill, no tube, no seal function, reducing the machine and mould loss.

PRODUCT SPECIFICATIONS

|

Model

|

HX-006

|

|

Power

|

2KW

|

|

Power supply

|

AC220V/110V 50/60Hz

|

|

Filling range

|

A3-30ml B6-60ml C10-120ml D25-250ml E50-500ml

|

|

Filling accuracy

|

±1%

|

|

Capacity

|

18-28pcs/min

|

|

Tube Dia.

|

15-50mm

|

|

Tube height

|

60-200mm

|

|

Working pressure

|

0.6MPa

|

|

Dimension

|

1200*900*1550mm

|

|

N.W

|

350kgs

|

|

G.W

|

380kgs

|

PRODUCT DETAILS

Working table Ten stations Tube holder will be production according to the diameter of tube.The working table adopts sandblasting process mar-proof

Tube holderI set=10pcs

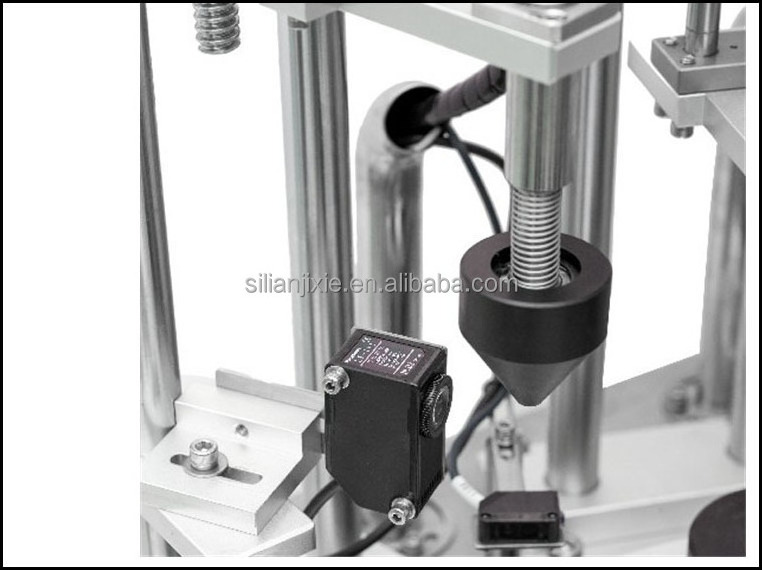

Panasonic Mark sensor,It is used to make date code on the sealing area.It support to date coding in the front or back.

Anti-dripping filling nozzle with blowing;with a variety of nozzles,suck back, And shut off after filling;Suit for stick cream,liqiuid or gel filling

Ultrasonic sealing horn with date code letter. 5-18digits printing custom made according to your requesting.

Two-way steel knife Trimming smoothly No burrs

APPLICATION SCENARIOS

COMPANY PROFILE

SALES AND SERVICE NETWORK

CERTIFICATE

PACKAGE AND TRANSPORT

FAQ

Q1. How About the Installation & Adjustment?

After the equipment arrived at the customer’s site, customers just need connect the machine with eletricity and air compressor,then the machine can run it,as we will shipping the machine with whole packed,customers no need to install the machine again when it arrived your factory.you can use or hire a forklift for unload the machine from the car.

Q2. Are There Training for Customers or our ?

We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users' technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.otherwise,we supply with Instructions in English language for each machine.

Q3. How about the "Quality Assurance"?

We are responsible for the faults and damages of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc. Each machine will be test and factory pre-adjust according to our customers real samples.we can take video for our customers to check before shipping, to make sure the machine quality and customers satisfaction.

Q4.How about the Warranty?

We offer 12 months maintenance period to the problems that caused by our design, manufacture, and material quality, and offer the relevant parts and effective services for free if the problems was caused by above reasons. We will offer a life-long technical support, after service for customers.

Hot Searches