- Product Details

- {{item.text}}

Quick Details

-

Printing width:

-

1800mm

-

Mechanical speed:

-

1-20 meters / minute

-

Heating drum diameter:

-

800mm

-

Power supply:

-

3 phase, 380V, 50HZ

-

Heating parts power rate:

-

60KW

-

Motor parts power rate:

-

5KW

-

Working temperature:

-

220-240 centigrade degree

-

Recommended working area:

-

4770*3200

-

Machine size / weight:

-

1850*3380*2000 / 4500KGS

-

Certification:

-

CE Certificate

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine type:

-

Heat transfer sublimation printing calenders machine

-

Printing width:

-

1800mm

-

Mechanical speed:

-

1-20 meters / minute

-

Heating drum diameter:

-

800mm

-

Power supply:

-

3 phase, 380V, 50HZ

-

Heating parts power rate:

-

60KW

-

Motor parts power rate:

-

5KW

-

Working temperature:

-

220-240 centigrade degree

-

Recommended working area:

-

4770*3200

-

Machine size / weight:

-

1850*3380*2000 / 4500KGS

-

Certification:

-

CE Certificate

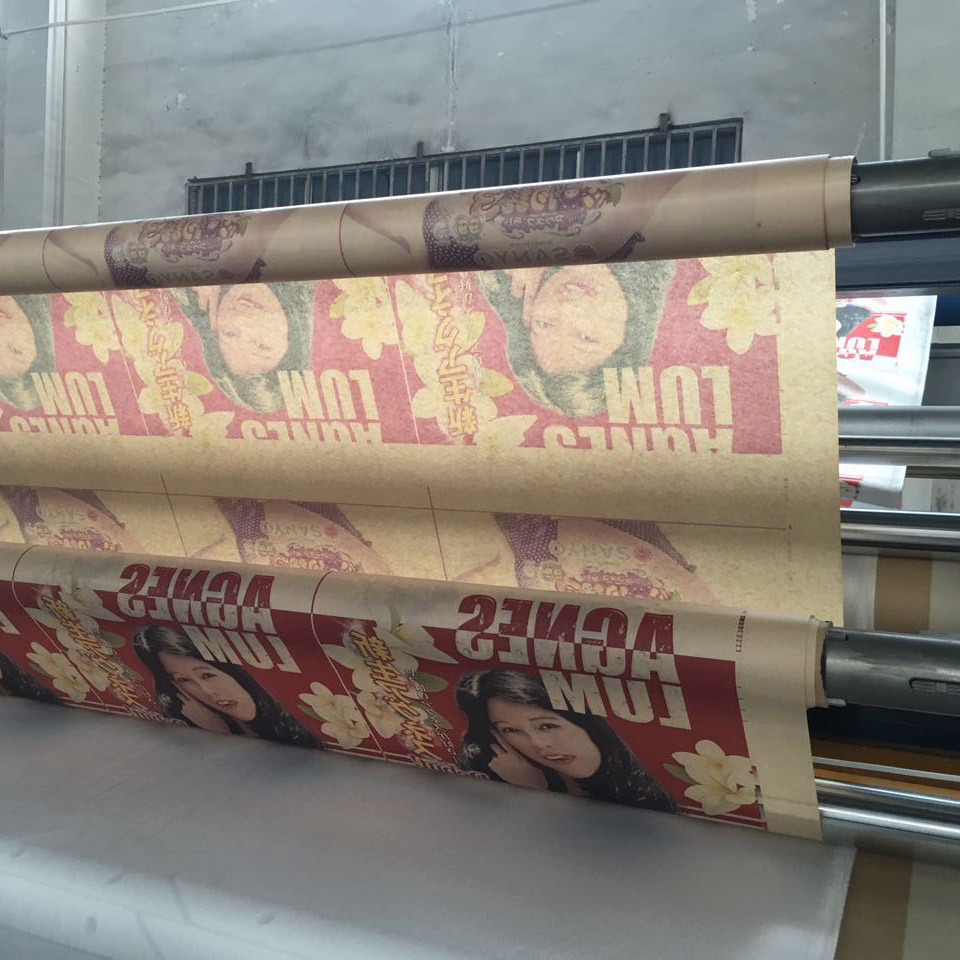

Heat transfer sublimation printing calenders machine

The Heat transfer sublimation printing calenders machine is designed to meet the increasing demand for high quality ink jet Dye-sublimation heat transfer technology . It is the perfect machine for industrial scaled producer who require high production speed and printing quality. Similar quality to Monti, but very economical price.

Main features:

1. Vacuum oil drum be heated by centralized resistor. Energy consumption saving and efficient, it just need 40 minutes to reach 200 ℃ working temperature . Temperature different will be controlled ± 1 ℃ .

2. Compact machine structure design for easy and safety operation. Very reasonable designed emergency stop structure to maximum protect the worker safety.

3. Automatic alignment device equipped

4. Electromagnetic system is used so even very thin paper can run on this machine properly.

5. All mechanical activities are completed by independent motor, therefore the problems brought b the electrical circuit or unfixed pulley system can be avoided.

6. Independent electrical cabinet design extended the machine life-span tremendously.

7. The safety system for the sudden power failure is provided.

8. The blanket can be separated from the heating drum manually according to user habit.

9. Machine switch on/off preset function is equipped.

10. For continuous production consideration, the second heat transfer paper roll loading is also equipped on this machine. In this way, fabric material is also maximum saved.

Technical parameters:

|

|

HM500-2000/2600/3300 |

HM800-2000/2600/3300 |

HM1000-2000/2600/3300 |

|

Oil drum width |

2000/2600/3300mm |

2000/2600/3300mm |

2000/2600/3300mm |

|

Oil drum dia. |

500mm |

800mm |

1000mm |

|

Working width |

1800/2400/2800mm |

1800/2400/2800mm |

1800/2400/2800mm |

|

Speed |

1-15m/min |

1-20m/min |

1-25m/min |

|

Machine size |

1850 X 3380/3860/4560 X 2000mm |

||

|

Net weight |

3.8MT |

4.5MT |

5MT |

|

Power rate |

48-65KW |

65-100KW |

80-120KW |

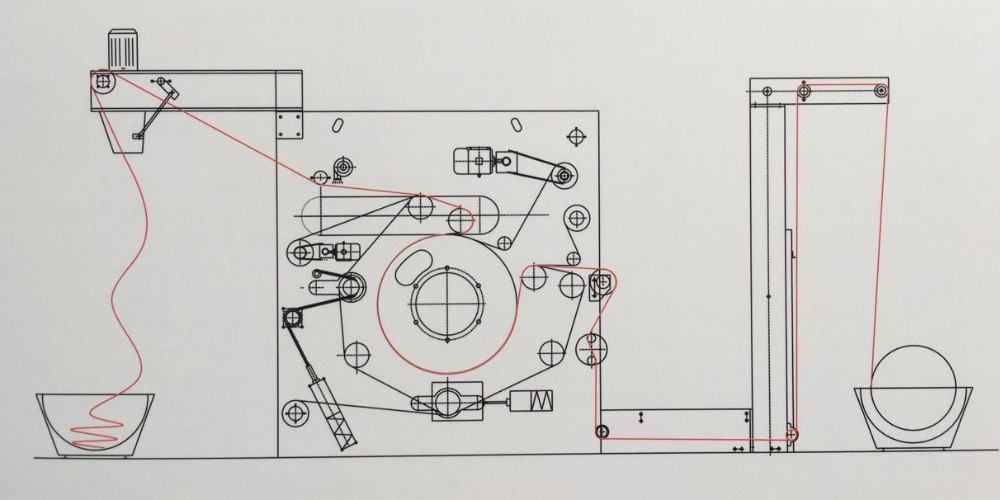

Machine schematic: