- Product Details

- {{item.text}}

Quick Details

-

Power:

-

/

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

LATINO

-

Dimension(L*W*H):

-

According to request

-

Weight:

-

Based the requested type on

-

Product name:

-

round shape water cooling tower for chiller

-

Application:

-

Industrial Cooling System

-

Keyword:

-

Industrial Towers Frp Cooling Tower

-

Water flow:

-

25~300t/h

-

Product material:

-

FRP/STEEL

-

Application Fields:

-

Industial

-

Shape:

-

Square Shape

-

Cooling Capacity:

-

50~300RT

-

Cooling Tower Type:

-

Counter Flow Circular Cooling Tower

-

Lead time:

-

15~25 Working Days

-

Certification:

-

CTI

Quick Details

-

Cooling Type:

-

Counter Flow

-

Material:

-

FRP

-

Voltage:

-

220/380

-

Power:

-

/

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

LATINO

-

Dimension(L*W*H):

-

According to request

-

Weight:

-

Based the requested type on

-

Product name:

-

round shape water cooling tower for chiller

-

Application:

-

Industrial Cooling System

-

Keyword:

-

Industrial Towers Frp Cooling Tower

-

Water flow:

-

25~300t/h

-

Product material:

-

FRP/STEEL

-

Application Fields:

-

Industial

-

Shape:

-

Square Shape

-

Cooling Capacity:

-

50~300RT

-

Cooling Tower Type:

-

Counter Flow Circular Cooling Tower

-

Lead time:

-

15~25 Working Days

-

Certification:

-

CTI

Round Shape Water Cooling Tower For Chiller

A cooling tower is a specialized heat exchanger in which air and water are brought into direct contact with each other in order to reduce the water’s temperature. As this occurs, a small volume of water is evaporated, reducing the temperature of the water being circulated through the tower.

Water, which has been heated by an industrial process or in an air-conditioning condenser, is pumped to the cooling tower through pipes. The water sprays through nozzles onto banks of material called “fill,” which slows the flow of water through the cooling tower, and exposes as much water surface area as possible for maximum air-water contact. As the water flows through the cooling tower, it is exposed to air, which is being pulled through the tower by the electric motor-driven fan.

When the water and air meet, a small amount of water is evaporated, creating a cooling action. The cooled water is then pumped back to the condenser or process equipment where it absorbs heat. It will then be pumped back to the cooling tower to be cooled once again. Cooling Tower Fundamentals provides a level of basic cooling tower knowledge and is a great resource for those wanting to learn more.

Types Of Cooling Towers

Not all towers are suitable for all applications. Cooling towers are designed and manufactured in several types, with numerous sizes available. Understanding the various types, along with their advantages and limitations, is important when determining the right tower for a project. The product list provides an overview of towers to help you determine which is right for your application.

Crossflow Cooling Towers

In crossflow towers the water flows vertically through the fill while the air flows horizontally, across the flow of the falling water.

Because of this, air does not have to pass through the distribution system, permitting the use of gravity flow hot water distribution basins mounted at the top of the unit above the fill.

These basins are universally applied on all crossflow towers.

Counterflow Cooling Towers

Counterflow towers are designed so that air flows vertically upward, counter to the flow of falling water in the fill.

Because of this vertical airflow, it is not possible to use the open, gravity-flow basins typical in crossflow designs. Instead, counterflow towers use pressurized, pipe-type spray systems to spray water onto the top of the fill.

Since air must be able to pass through the spray system, the pipes and nozzles must be farther apart so as not to restrict airflow.

Induced Draft vs. Forced Draft Cooling Towers

Induced draft cooling towers have fans that are typically mounted on top of the unit and pull air through the fill media. Conversely, air is pushed by blowers located at the base of the air inlet face on forced draft towers.

Factory Assembled (FAP) vs. Field Erected (FEP) Cooling Towers

Factory-assembled towers (FAP) are built and shipped in as few sections as the mode of transportation will permit. A relatively small tower will ship essentially intact. A larger, multi-cell cooling tower is manufactured as modules at the factory, and shipped ready for final assembly. Factory-assembled towers are also known as “packaged” or “FAP” (factory-assembled product). Factory-assembled cooling towers can be crossflow or counterflow, induced draft or forced draft, depending on the application. While all applications are different, the factory-assembled Marley NC crossflow, induced draft tower is widely used for HVAC and light industrial applications.

Field-erected cooling towers (FEP) Field-erected towers are primarily constructed at the site of ultimate use. All large cooling towers, and many of the smaller towers, are prefabricated, piece-marked, and shipped to the site for final assembly. The manufacturer usually provides labor and supervision for final assembly. Field-erected towers can be crossflow or counterflow, depending on the application. For power and heavy industrial applications, the field-erected Marley F400 counterflow tower can be customized to meet your exact specifications for performance, structure, drift and plume abatement.

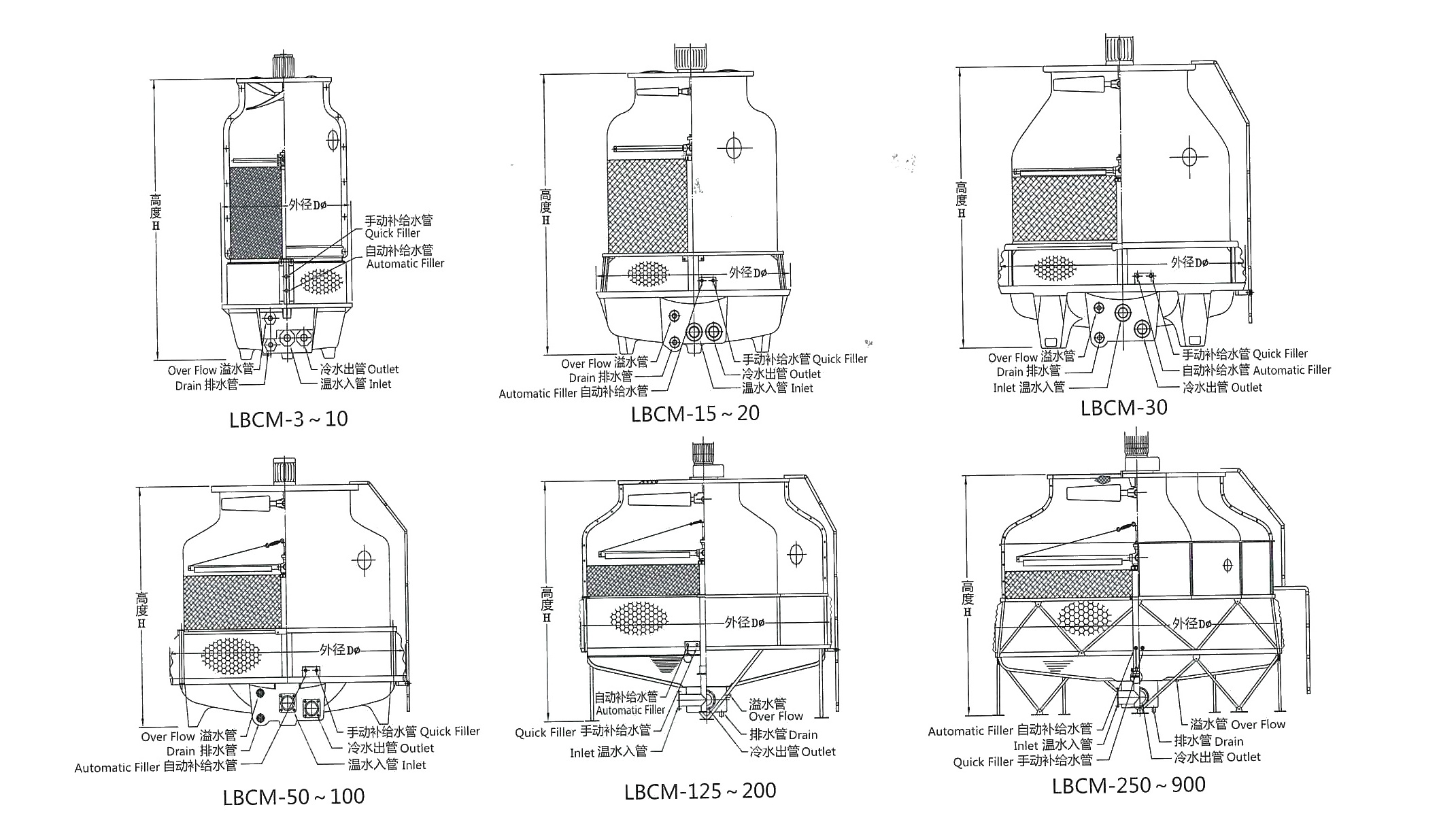

| Modle | water Flow | Motor | Fan | Dimensions | Pipe Connection | |||||||

| M3/H | MM | Inlet | Outlet | Drain | Over Flow | |||||||

| LBCM- | LBC- | WB28ºC | WB27ºC | KW | Hp | D(mm) | H | D | mm | |||

| 3 | 2.1 | 2.5 | 0.12 | 1/6 | 500 | 1335 | 750 | 25 | 25 | 20 | 25 | |

| 3 | 5 | 3.2 | 3.7 | 0.12 | 1/6 | 500 | 1410 | 750 | 40 | 40 | 20 | 25 |

| 5 | 8 | 5.5 | 6.6 | 0.12 | 1/6 | 500 | 1690 | 860 | 40 | 40 | 25 | 25 |

| 10 | 6.7 | 7.8 | 0.18 | 1/4 | 670 | 1835 | 1060 | 40 | 40 | 25 | 25 | |

| 10 | 15 | 10 | 11 | 0.18 | 1/4 | 670 | 1940 | 1170 | 50 | 50 | 25 | 25 |

| 20 | 13.5 | 15.6 | 2110 | 1170 | 0.18 | 1/2 | 770 | 50 | 50 | 25 | 25 | |

| 25 | 17 | 20.4 | 2170 | 1170 | 0.37 | 3/4 | 770 | 50 | 50 | 25 | 25 | |

| 30 | 20 | 23.5 | 2205 | 1380 | 0.55 | 1 | 770 | 65 | 65 | 50 | 25 | |

| 40 | 27 | 31.2 | 2117 | 1580 | 0.75 | 1.5 | 970 | 65 | 65 | 50 | 25 | |

| 30 | 50 | 34 | 39.7 | 2410 | 1820 | 1.1 | 1.5 | 970 | 65 | 65 | 50 | 25 |

| 60 | 42 | 46.8 | 2137 | 2000 | 1.1 | 1.5 | 1170 | 80 | 80 | 50 | 25 | |

| 70 | 47 | 53 | 2287 | 2000 | 1.1 | 1.5 | 1170 | 100 | 100 | 50 | 25 | |

| 50 | 80 | 55 | 63.5 | 2565 | 2175 | 1.5 | 2 | 1170 | 100 | 100 | 50 | 25 |

| 65 | 100 | 70 | 81.9 | 2645 | 2175 | 2.2 | 3 | 1470 | 100 | 100 | 50 | 25 |

| 80 | 125 | 86 | 100.5 | 2780 | 2650 | 2.2 | 3 | 1470 | 125 | 125 | 50 | 50 |

| 100 | 150 | 103 | 118.5 | 2785 | 3300 | 3.7 | 5 | 1750 | 125 | 125 | 50 | 50 |

| `175 | 123 | 134.5 | 2885 | 3300 | 3.7 | 5 | 1750 | 125 | 125 | 50 | 50 | |

| 125 | 200 | 137 | 158.9 | 3490 | 3770 | 3.7 | 5 | 1750 | 125 | 125 | 50 | 50 |

| 150 | 225 | 158 | 181.5 | 3690 | 3770 | 5.5 | 7.5 | 2350 | 150 | 150 | 50 | 50 |

| 175 | 250 | 175 | 205 | 3690 | 3770 | 7.5 | 10 | 2350 | 150 | 150 | 50 | 50 |

| 200 | 300 | 215 | 247.3 | 3850 | 4440 | 7.5 | 10 | 2350 | 200 | 200 | 50 | 100 |

| 350 | 243 | 284.0 | 4180 | 4790 | 7.5 | 10 | 2350 | 200 | 200 | 50 | 100 | |

| 250 | 400 | 277 | 324.6 | 4340 | 5180 | 11 | 10 | 2970 | 200 | 200 | 50 | 100 |

| 300 | 450 | 320 | 368.1 | 4430 | 5580 | 11 | 15 | 2970 | 200 | 200 | 50 | 100 |

| 350 | 500 | 355 | 408.3 | 4430 | 5580 | 15 | 15 | 3380 | 250 | 250 | 50 | 100 |

| 400 | 600 | 415 | 477.3 | 4790 | 6600 | 15 | 20 | 3380 | 250 | 250 | 50 | 100 |

| 450 | 700 | 460 | 534.7 | 4790 | 6600 | 22 | 30 | 3580 | 250 | 250 | 80 | 100 |

| 500 | 800 | 509 | 592.5 | 5300 | 7600 | 22 | 30 | 3580 | 250 | 250 | 80 | 100 |

| 600 | 900 | 615 | 707.5 | 5745 | 7600 | 22 | 30 | 3580 | 300 | 300 | 80 | 100 |

| 700 | 1000 | 710 | 816.6 | 5745 | 8430 | 30 | 40 | 4270 | 300 | 300 | 80 | 100 |

| 750 | 1100 | 765 | 867 | 6220 | 8430 | 30 | 40 | 4270 | 300 | 300 | 80 | 100 |

| 800 | 1200 | 800 | 920 | 6520 | 8430 | 30 | 40 | 4270 | 300 | 300 | 80 | 100 |

| 900 | 1350 | 900 | 1032 | 6520 | 8430 | 37 | 50 | 4270 | 300 | 300 | 80 | 100 |

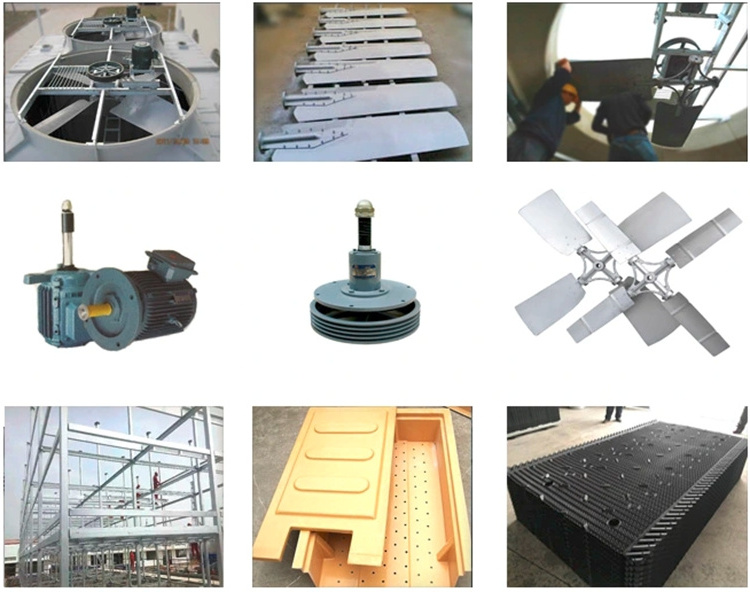

02- Liangchi Cooling Tower Accessories

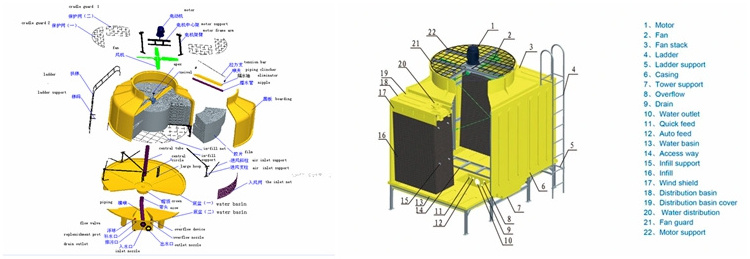

03-Schematic Diagram

04 The Limited Value of Water Analysis

| Parameter | Make up water | Circulating Water | Parameter | Make Up Water | Circulating Water |

| PH Value | 6-8 | 6-8 |

Chloric Acid IOD

(CL-) ppm |

50blew | 200blew |

| Electric Conductivity | 200below | 500blew | Sulphuric ACID ION ppm | 50blew | 200blew |

| Total Hardness | 50blew | 200blew | Silicic ACID ppm | 30blew | 50blew |

| Malkainity | 50blew | 100blew | Ferric (Fe) ppm | 0.3blew | 0.1blew |

05-Instruction For The Cooling Tower Components

CASING AND WATER BASIN

Fiberglass reinforced polyester (FRP) is produced with the water-resistance resin and superior quality fiberglass mat. With good moisture, high gel,high strength, spray the gel-coat on FRP parts by machine and is thermal formed.

FAN & DRIVING SYSTEM

All the cooling tower fans with the adjustable pitch blades are applied to being balanced, it operates stably and quietly. The material for cooling tower fan are A.B.S, aluminum alloy for normal standard, F.R.P or stainless steel material available for all your options.Small capacity cooling tower adopts direct drive low noise fan. Bigger capacity fan equipped with Belt drive speed reducer or Gear box.

WATER DISTRIBUTION SYSTEM

Using high coefficient rotating sprinkler head which is made of plastic or aluminum alloy could reduce the pressure of friction loss, and the water can be distributed evenly to achieve the max thermal cooling performance.

COOLING TOWER FILL PACKING

Used high quality & improved performance PVC with good material, it is high cooling efficiency and anti-corrosive & UL V-0. The surface of cooling tower infill is corrugated to increase the filling pitch to make sure that infill is clog-free and overcome the problem of water quality. Special material for option if high entering water temperature.

COOLING TOWER FRAME

The cooling tower framework is made of hot dip galvanized steel (HDGS) or FRP, to makes the cooling tower in rust-free, durable and long service life.

06- Relevant Cooling Towers

WORKING PRINCIPLE

1. Working fluid (water, oil or other flowing liquid) flowing inside of the coils, which is enwrapped by the cooling tower spray water on the outside. The heat of working fluid is transferred by the coil and become the saturated vapor when meeting the water and air.

2. The heat is exhausted out of the cooling tower by the cooling tower by the top fan; water is collected back to the bottom tank and circulates continuously. The cooling tower spray water is cooled down via cooling tower PVC fill in the process of

circulation, and flow is the same direction with the fresh wind. The coil mainly takes sensible heat travel style.

3. The most benefit of this style is can avoid scale formation on the outside of the coil. And this will apply especially to

dealing with high-temperature fluid (e.g. 60°C) or the fluid need big temperature difference (e.g. 60°C to 32°C).

Cooling tower body structure and performance

This fiber reinforced plastic cooling tower body is made of high-quality fiberglass reinforced plastics, the rubber coating

surface of which is made of imported raw materials, which is even in color and will not fade or degrade easily.All structure parts made of steel are processed in hot-galvanizing.Injected molded parts are used widely for they are erosion-proof, high in intensity, light in weight and easy to attach.

The cooling tower has a successful water floating control, rendering a loss less than 0.001%.

-Use low-speed wind machine to avoid too much water spray in the air;

-Use waterproof sleeves on water distribution pipes to collect spilled water;

-The ground frame is larger than enclosure and is equipped with PVC shutters to avoid water spilling out of the tower.

Advantages

Low-noise control principle

Lower noise from the sound source.The special power machine is filled closed automatic cooling type low-noise cooling tower.Such kind of machine is good at water-proof performance, low in noise.

1.Low-speed fan to avoid excessive mist into the air.

2.FRP body contains stable materials resisting ultraviolet radiation with a long service life.

3.Filled with round counterflow model film.

4.Rotating pipe distributing model.

5.The structure contains rust-removing and high-strength galvanized steel which can bear corrosion and can be easily assembled.

6.Different types(standard,low-noise,high-temperature and industrial type) to meet your needs.

Main Features

1, Cooling tower is mainly used for cooling in air conditioning system, frozen series, injection molding, leather, foam, power

generation, steam turbine, aluminum processing, air compressors, industrial cooling water and other fields;

2, Most used for air conditioning cooling, freezing, plastic chemical industry;

3, Closed circuit cooling tower have the Attractive shape: the Small dimension of shape, the low height of the tower, light weight of tower, and multiform layout in covering the area.