- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yuanda

-

Voltage:

-

380V

-

Power:

-

300-500

-

Weight:

-

40000 kg

-

Voltage::

-

220/380/415/480V. 50/60Hz

-

Machine type::

-

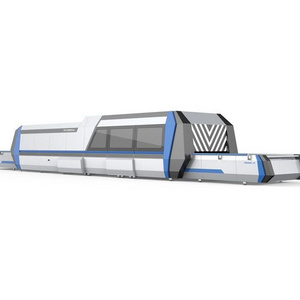

Horizontal flat tempering furnace

-

Max.glass Width(mm):

-

2400

-

Max.glass Length(mm):

-

6000

-

Glass thickness(mm)::

-

4-19

-

Name:

-

glass tempering machine

-

Min glass size:

-

100x100mm

-

Control system:

-

Touch Screen Computer

-

Tempering type:

-

Flat Glass Tempering

-

Application:

-

Architectures Furniture Household Appliance

Quick Details

-

Machine Type:

-

Glass Tempering Furnace

-

Glass Thickness:

-

4-19mm

-

Production Capacity:

-

10

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yuanda

-

Voltage:

-

380V

-

Power:

-

300-500

-

Weight:

-

40000 kg

-

Voltage::

-

220/380/415/480V. 50/60Hz

-

Machine type::

-

Horizontal flat tempering furnace

-

Max.glass Width(mm):

-

2400

-

Max.glass Length(mm):

-

6000

-

Glass thickness(mm)::

-

4-19

-

Name:

-

glass tempering machine

-

Min glass size:

-

100x100mm

-

Control system:

-

Touch Screen Computer

-

Tempering type:

-

Flat Glass Tempering

-

Application:

-

Architectures Furniture Household Appliance

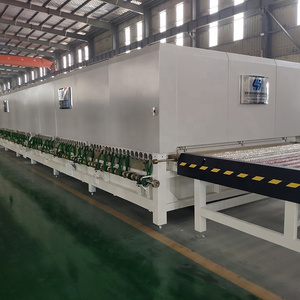

Big size glass 2.8*6m tempered glass making machine tempering furnace

,

Machine specification

Total length of the machine:26m,main body: 5M, cooling fan:40-60m2

Machine Parameters

|

Max. glass dimension |

2800mm×6000mm |

|

Min. glass dimension |

100mm×300mm |

|

Glass thickness range |

4~19mm |

|

Output |

247 m 2 /hour (5mm float glass, loading rate 85%) |

|

Power |

1312KW |

Glass type

Transparent float glass or flat glass

Mass color float glass or flat glass

Single side printed glass

On line low-e glass

Off line low-e glass (convection type furnace)

Quality Standard of glass

The product meets to Chinese national quality standard<GB 15763.2-2005>

Glass stress equilibrium, particle even

Quality of all finished glass are the same

Heat resistance: confront to international standard

1. Easy and human friend control system.

l The machine use Beckhoff control system with very intelligent and easy operation page. All parameter can be set on screen page;

l For each type of glass, the operator can save the relating parameter as a formula , save it into the computer. Can select and use it for next production.

2. Energy saving.

l The machine use advance arrangement of heating wires, reasonable distance from heating wire to glass, DIN heating control system to enable energy saving. Less than 4kw/m2 for 5mm thickness glass.

l It also can design passing section for 4mm or 5mm thickness glass to save energy when the machine process glass over 6mm.

l With converter for blowers.

l Use of high quality heating protect brakes to prevent heating escape.

3. High quality glass

l The tempered glass meet with Chinese high standard of tempered glass GB15763-2005 for tempering glass used for building.

l Breaking particles: in a position of 50*50mm, the breaking pieces shoud over 50pcs for 4-12mm glass and over 40pcs for glass over 15mm. (The actual breaking rate may higher than this)

l Surface stress of glass will not less than 90MPa.

l Can understand 200 degree te mperature difference

4 High quality parts used on the whole machine

l The whole machine u ses high quality steel, heating wires, ceramic rollers, electric parts, heating reserve parts.

5. Experienced in new glass processing factory supply.

l Assist for glass tempering plant in Romania, Saudi Arabia, United State, Egypt, Australia, Uzbekistan, Turkey etc.

6. Engineers for machine set up

l We sent engineer to set up the machines when machines and workshop are ready. At present, our engineers went to over 20 countries, includes USA, Romania, Saudi Arabia, Egypt, Australia, Guatemala,Turkey, Poland, Czech, Bulgaria etc to install and commissioning the machines.

Succesful project recently:

Project 1:

Project 2:

Project 3:

Project 4:

Warranty: Warranty period of the whole machine: one year

Machine commissioning and training: Send engineers to set up and commissioning at buyer’s factory.

Aftersales service:

Life time techical and parts support.

On port techcial training or problem solving when necessary