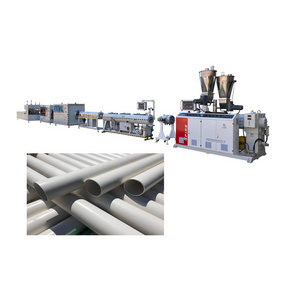

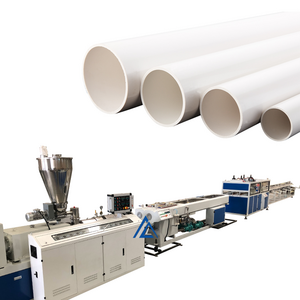

PVC pipe production line / PVC extruder/ PVC pipe extrusion machine

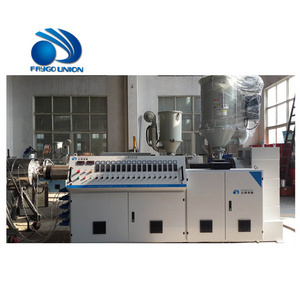

Φ 20- Φ 630 series PVC pipe extrusion machine line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agricultural and constructional plumbing,cable laying etc. This line is composed of conical twin screw extruder,Vacuum calibration tank,haul off,motors,cutter and stacker etc. The extruder and haul off methods are two-claw,three-claw four-claw,six-claw,eight-claw,ten-claw,twelve claw etc. You may choose saw blade cutting type or planetary cutting type. It is aditionaly attached with length counter and intensifying device. This line with reliable performance and high production eficiency. Our company can also manufacture special pipe production lines,e.g. spiral silencing pipe and core foaming pipe according to your requirements.

PVC pipe making machine performance

1.Replacement molds can produce pipes with different diameters.

2.With a set of molds to produce two or four tubes at the same time.Increased production efficiency.

3.More cost-effective production line.

4.Greatly saving the use of the factory space.

5.High energy efficiency.Just a set of power systems.

6.Can significantly reduce the number of operators.

7.Simple operation.

Processing flow of Pvc Electric Conduit water Pipe Making Machine production line

PVC powder + additive → mixing → spring feeding → twin screw extruder → mould and calibrator → vacuum forming machine → haul off machine → cutting machine → discharging rack