- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BOSUN

-

Model Number:

-

201;202;410;430;304

-

Usage:

-

Surface cleaning, rust removal, peening

-

Keyword:

-

stainless steel shot

-

Product name:

-

stainless steel cut wire shot

-

material:

-

stainless steel

-

Certificate:

-

ISO9001:2008

-

Shape:

-

cylinders;round

-

Sample:

-

Sample Provided

-

Size:

-

Customer Size

-

Hardness:

-

40-60HRC

-

MOQ:

-

5 Tons

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

0.3mm--2.5mm

-

Place of Origin:

-

China

-

Brand Name:

-

BOSUN

-

Model Number:

-

201;202;410;430;304

-

Usage:

-

Surface cleaning, rust removal, peening

-

Keyword:

-

stainless steel shot

-

Product name:

-

stainless steel cut wire shot

-

material:

-

stainless steel

-

Certificate:

-

ISO9001:2008

-

Shape:

-

cylinders;round

-

Sample:

-

Sample Provided

-

Size:

-

Customer Size

-

Hardness:

-

40-60HRC

-

MOQ:

-

5 Tons

stainless steel shot and stainless steel cut wire shot

Bosun stainless shot is delicately with the process of drawing, cutting, and conditioned etc. and with the appearance of brightness, restlessness and spherical beads (for cut wire shot, cylinders). It’ s also called Conditioned stainless steel cut wire shot. And they are widely used for the surface preparation by peening and blasting on Copper, Aluminum, Zinc and stainless steel work pieces etc. So, the work can illustrate their metal color with sub-light effects and die casting restlessness after preparation. There is no need to adopting rust moving treatment by acid cleaning. Besides their abrasion resistance is 3-5 times as much than cast stainless steel shot, so the production could be cut down.

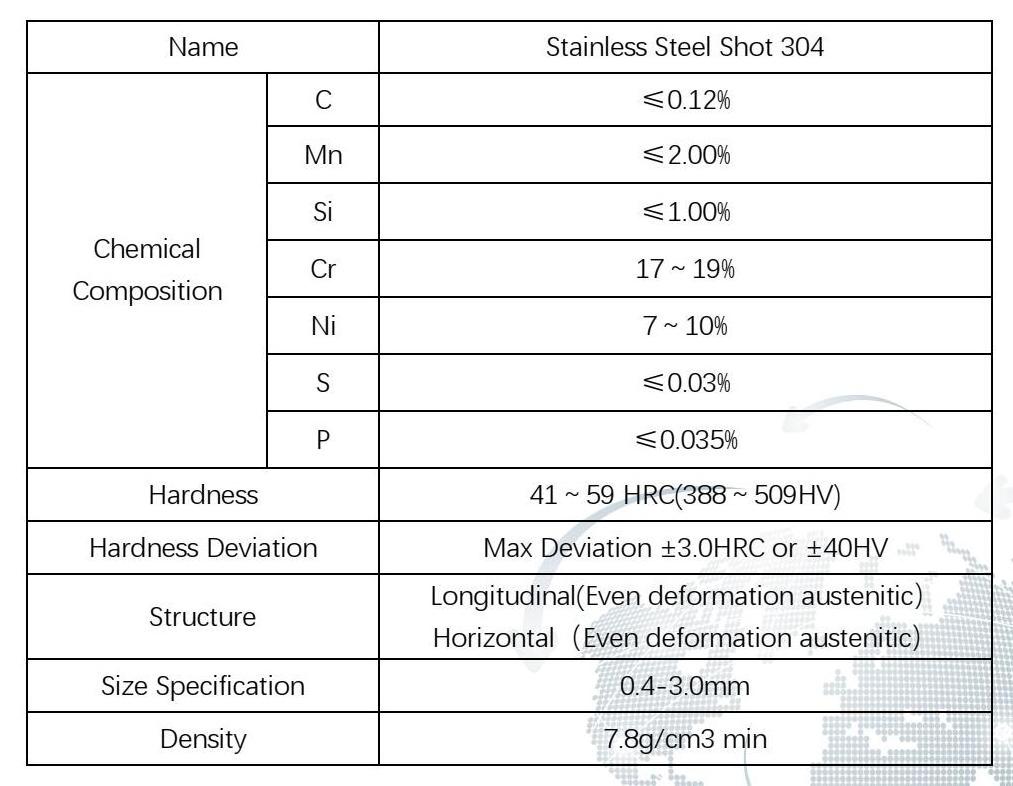

Technical Specifications & Characteristics

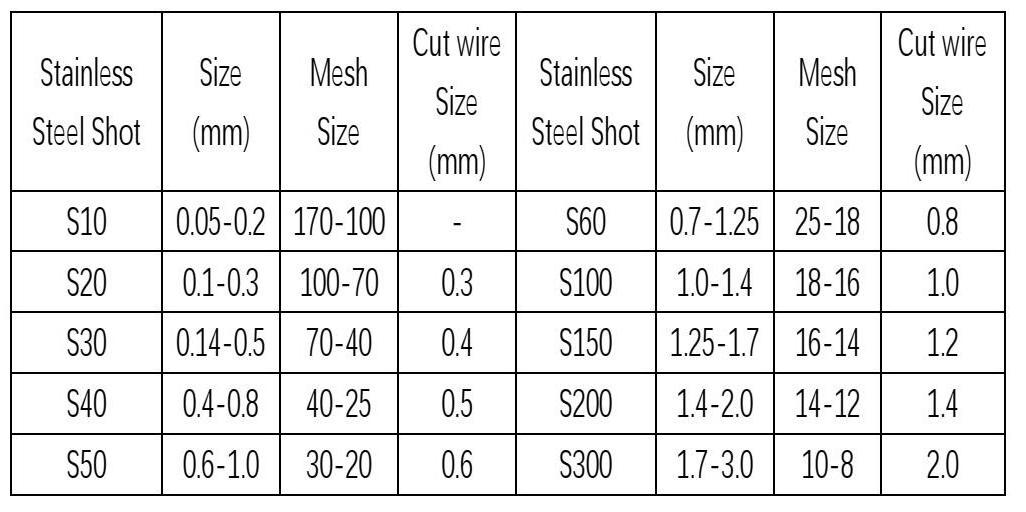

Size specification

| Chemistry composite of stainless steel shot (%) | |||||||

| Grade | C (Max) | Mn (Max) | P (Max) | S (Max) | Si (Max) | Cr | Ni |

| 201 | 0.15 | 8.0-10.5 | 0.08 | 0.03 | 1.0 | 13.0-16.0 | 1.8 |

| 202 | 0.15 | 7.0-10.0 | 0.06 | 0.03 | 1.0 | 14.0-16.0 | 3.8 |

| 304 | 0.08 | 2.0 | 0.04 | 0.03 | 1.0 | 18.0 - 20.0 | 7.8 |

| 410 | 0.08 | 1.0 | 0.04 | 0.03 | 1.0 | 11.5- 13.5 | 0.6 |

| 430 | 0.12 | 1.0 | 0.04 | 0.03 | 1.0 | 16.0- 18.0 | 0.75 |

Advantages

√ Exceeding the life of aluminum oxide, glass beads, mineral abrasives, garnet or slag by nearly 1000 to 1, it can significantly reduce your raw material and disposal costs.

√ Uniform hardness, density and microstructure, coupled with good toughness for durability

√ High Density and strength for fast blast rate, low break down rate and low dust

√ After treatment, the surface of the castings is not rusty. It is not necessary to carry out acid washing and other post treatment. It is beneficial to environmental protection

Some pictures showing product details

Certificates

Applification

√ All types of aluminum castings and forgings

√ Non-ferrous metals and special alloys

√ Stainless steel castings and forgings

√ Apparatus and welded structures in stainless steel

√ Other application

Our services

1. Free samples: we can supply 200gs samples for free.

2.Direct manufacturer.

3. High quality : our product have passed ISO quality.

4. After sales service: we can supply technical service for free.

For any questions pls contact me freely!

Any interest in my product, pls feel free to contact with me, you can call me directly.

I am here waiting for you. Many thanks.

Rita Zhang

Mob: +86 13127901320

Skype: +86 13127901320

WhatsApp/Wechat: +86 13127901320

Email: rita.zhang(at)chinabosun.com

TM:cn1519047498sjzd