- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Gondor

-

Type:

-

Peeling machine, Peeling machine

-

Voltage:

-

380v

-

Power:

-

1.5kw

-

Weight:

-

110 KG

-

Dimension(L*W*H):

-

600*700*1700mm

-

Year:

-

2024

-

Core selling point:

-

High efficiency, suitable for a variety of fruits.

-

Applicable raw materials:

-

Winter melon;small pumpkin;pumpkin;taro;pineapple ;watermelon

-

Working head:

-

Double

-

Capacity:

-

150-240 pcs/h

-

Material:

-

stainless steel

-

Finished product name:

-

Pineapple

-

OEM/ODM Service:

-

Acceptable

-

Function:

-

Fruit peeling work

-

Usage:

-

Commercial usage

Quick Details

-

Marketing Type:

-

Hot Product

-

Core Components:

-

Automatic stroke sensor, Control pedal, Cylinder

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gondor

-

Type:

-

Peeling machine, Peeling machine

-

Voltage:

-

380v

-

Power:

-

1.5kw

-

Weight:

-

110 KG

-

Dimension(L*W*H):

-

600*700*1700mm

-

Year:

-

2024

-

Core selling point:

-

High efficiency, suitable for a variety of fruits.

-

Applicable raw materials:

-

Winter melon;small pumpkin;pumpkin;taro;pineapple ;watermelon

-

Working head:

-

Double

-

Capacity:

-

150-240 pcs/h

-

Material:

-

stainless steel

-

Finished product name:

-

Pineapple

-

OEM/ODM Service:

-

Acceptable

-

Function:

-

Fruit peeling work

-

Usage:

-

Commercial usage

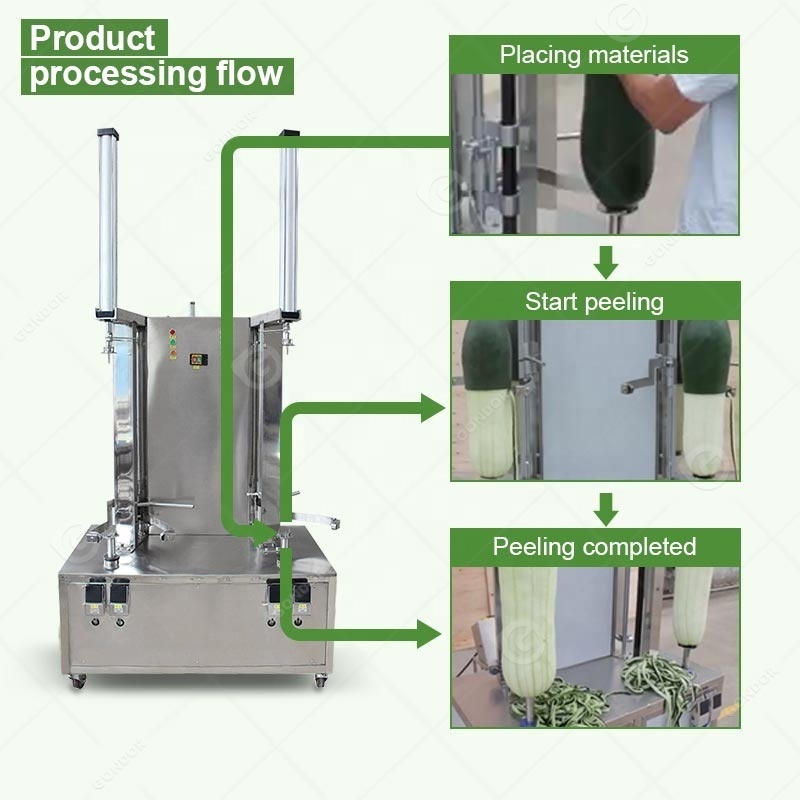

Introduction

Pineapple peeler machine is composed of a peeler, a cylinder, a control switch, a gear lever, and other components, used for peeling various fruits such as pineapples. Suitable for various occasions such as the catering industry, canteens, food processing factories, etc.

Pineapple peeling machine has the characteristics of fast peeling speed, wide application range, simple operation, high efficiency, convenient cleaning, safety and hygiene, and is an ideal equipment for peeling various fruits and melons.

Application

1. Pineapple peeling machine is specially designed for peeling large and medium-sized melons such as pineapple, papaya, pumpkin, cantaloupe, watermelon, winter melon, grapefruit, etc., with high efficiency and good quality.

2. Pineapple peeler machine is widely used in restaurants, canteens, agricultural and sideline products processing plants, clean vegetable distribution centers, food processing plants and central kitchens and other occasions.

Features

1.

The peeling thickness of the pineapple peeling machine is adjustable and easy to use.

2.

The cutting efficiency of the knife group is high up and down, and the peeling rate reaches more than 90%.

3.

Pineapple peeler machine is made of stainless steel, which has good structural strength and is not easy to rust.

4.

Simple operation, convenient cleaning, safe and hygienic.

Paramater

| Model | GD-100-1 | GD-100-2 | GD-100-22 | GD-200 |

| Capacity | 180 pcs/h | 150-200 pcs/h | 150-200 pcs/h | 150-240 pcs/h |

| Size | 600*700*1700mm | 420*590*1030mm | 420*590*1030mm | 1200*720*1800mm |

| Voltage | 380v | 220V | 220V | 380v |

| Power | 0.75kw | 0.5kw | 0.5kw | 1.5kw |

| Weight | 110kg | 55kg | 55kg | 190kg |

Q1 What is a pineapple peeler machine? What is its purpose?

Pineapple peeler machine is a mechanical device specifically designed to remove the outer skin of pineapple and mango pulp, in order to improve efficiency and reduce manual labor intensity. It can be widely used in food processing factories, fruit processing factories, and other places.

Q2 What is the principle of a pineapple peeler machine?

Pineapple peeling machine uses a combination of rotating blades and transmission devices to cut and remove the outer skin of pineapple, as well as remove the outer skin of mango flesh. The rotating blades of the machine can quickly remove the outer skin and improve processing efficiency.

Q3

How to solve the failure of the machine during use?

If necessary, you can send us the detailed information and fault statement of the machine with photos or videos, then we will provide you with professional guidance and suggestions until the machine works normally.

Q4 How about the quality of the machine?

This machine is tested repeatedly from material selection to processing, manufacturing, and forming to ensure product quality.

Q5

Which details are important before ordering the processing line?

Before making an accurate plan for you, your factory's processing materials, capacity requirements, floor plans, and your customized requirements should be provided to us.

Install waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Delivery Time

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.